- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cryo Systems

-

Capacity:

-

0~18000KW

-

Temperature:

-

-70~+20 °C

-

Refrigerant:

-

R717/R22/R404A

-

Voltage:

-

380V/400V/440V

-

Climate class:

-

SN, N, ST, T

-

Certification:

-

ce

-

Marketing Type:

-

New Product 2021

Quick Details

-

Type:

-

Screw

-

Application:

-

Refrigeration equipment

-

Weight (KG):

-

1030

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cryo Systems

-

Capacity:

-

0~18000KW

-

Temperature:

-

-70~+20 °C

-

Refrigerant:

-

R717/R22/R404A

-

Voltage:

-

380V/400V/440V

-

Climate class:

-

SN, N, ST, T

-

Certification:

-

ce

-

Marketing Type:

-

New Product 2021

About Us

Products Description

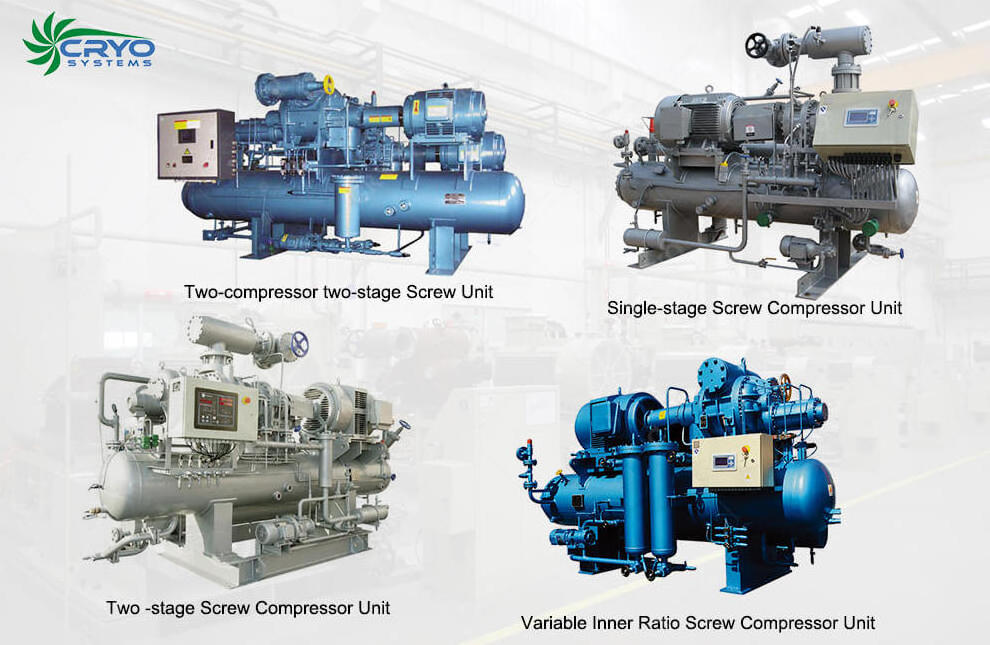

We have many kinds of Screw compressor units

|

Compresor Units Type

|

Open Type single-stage Screw Compressor Unit

Open Type Dual-stage Screw Compressor Unit Variable Inner Ratio Screw Compressor Unit Dual-compressor two-stage Screw Unit Semi-hermetic Two-stage Screw Compressor Unit and so on |

|

Refrigerant

|

Ammonia (R717),

Freon (R22 R744 R507A R404A R290 R1270) |

|

Temperature

|

-70~+20deg.C

|

|

Cooling Capacity

|

0~18000kw

|

|

Capacity Scope

|

Theoretical Exhaust Volume: 624~4800m3/h

|

|

|

Refrigeration capacity:144~1191 kW/153~1526.3kW/148~2636kW

|

|

Application

|

food processing, cold logistics, slaughter, aquaculture, chemical industry, and so on

|

Design Features of Screw Refrigeration Compressor Unit

|

Refrigerant

|

R717

|

R22

|

|

|

Discharge pressure MPa

|

below 1.67

|

below 1.67

|

|

|

Corresponding saturated temperature °C

|

below 45

|

below 46

|

|

|

Suction pressure MPa

|

-0.615

|

-0.637

|

|

|

Corresponding evaporative temperature °C

|

-57.5

|

-57.5

|

|

|

Volume ratio adjustment

|

2.5~5.0 stepless adjustment

|

|

|

|

Energy level adjustment

|

10~100% stepless adjustment

|

|

|

|

Oil Temperature (ºC)

|

25~65 °C

|

|

|

Features

1. The latest contemporary technology

2. Large capacity and low noise

3. Super sealed

4. High reliability and high efficiency

5. Microcomputer controlled

6. Precisely circulation oil control

2. Large capacity and low noise

3. Super sealed

4. High reliability and high efficiency

5. Microcomputer controlled

6. Precisely circulation oil control

Our Advantages

Two-stage Screw Compressor Unit

1. The unit adopts a modular design, compact structure, reasonable layout, and reliable operation.

2. Circulation mode: incomplete cooling in the middle of two-stage compression and one-stage throttling, low-pressure stage with economizer

3. High Reliability

2. Circulation mode: incomplete cooling in the middle of two-stage compression and one-stage throttling, low-pressure stage with economizer

3. High Reliability

- Sliding bearing, long operating life

- Less wearing parts, smooth operation, suitable for long-term operation

4. High efficiency

- Less wearing parts, smooth operation, suitable for long-term operation

4. High efficiency

-

The exhaust temperature of the unit is low, high volumetric efficiency

- World's leading screw compressor rotor profile, high efficiency

- Energy step-less adjustment

- Adopt a high-efficiency oil separator and high-efficiency oil cooler to ensure low oil consumption and high heat exchange

efficiency of the unit

5. Intellectualized:

- Manual control and microcomputer automatic control

- The special microcomputer controller, strong control capability. And realize modulation and networking

- World's leading screw compressor rotor profile, high efficiency

- Energy step-less adjustment

- Adopt a high-efficiency oil separator and high-efficiency oil cooler to ensure low oil consumption and high heat exchange

efficiency of the unit

5. Intellectualized:

- Manual control and microcomputer automatic control

- The special microcomputer controller, strong control capability. And realize modulation and networking

Single-stage Screw Compressor Unit

1. Perfect structure and reliable performance

* Single compressor realized two-stage compression, compact structure, reasonable layout, nice appearance, and simplifies the configuration of the refrigeration system. (can be equipped with Bitzer/Mycom compressor)

* Imported mechanical seal, simple structure, easy installation, excellent sealing performance to ensure continuous and

long-term stable operation of the compressor

* Advanced processing equipment and technology to ensure more accurate processing accuracy and higher efficiency, improve the reliability of the compressor operation

* Whole rolling has low noise, small vibration, rotor precise ,which ensures continuous operation and long life of the

compressor.

* Oil cooler can adopt water cooling or thermal siphon cooling

2. High efficiency and energy saving

* Small single-stage pressure ratio and high COP value in large pressure ratio condition

* World's leading screw compressor rotor profile, high efficiency

* Compressor differential pressure oil supply, saving power consumption, improving the reliability of the oil pump

* Both high and low stage using step-less adjustment energy to ensure efficient operation

* Adopting high efficient oil separator to ensure that oil fuel consumption is ≤5ppm, ensuring unit with low fuel consumption

* High precision suction and oil filter element

3. Ultra low-temperature screw compressor unit

* Evaporative temperature as low as -55 ℃

4. Intellectualized

* Automatic microcomputer control, run faster, more reliable, more powerful control, has achieved a modular, network, and also has a beautiful appearance, convenient operation, friendly interface, etc

* Single compressor realized two-stage compression, compact structure, reasonable layout, nice appearance, and simplifies the configuration of the refrigeration system. (can be equipped with Bitzer/Mycom compressor)

* Imported mechanical seal, simple structure, easy installation, excellent sealing performance to ensure continuous and

long-term stable operation of the compressor

* Advanced processing equipment and technology to ensure more accurate processing accuracy and higher efficiency, improve the reliability of the compressor operation

* Whole rolling has low noise, small vibration, rotor precise ,which ensures continuous operation and long life of the

compressor.

* Oil cooler can adopt water cooling or thermal siphon cooling

2. High efficiency and energy saving

* Small single-stage pressure ratio and high COP value in large pressure ratio condition

* World's leading screw compressor rotor profile, high efficiency

* Compressor differential pressure oil supply, saving power consumption, improving the reliability of the oil pump

* Both high and low stage using step-less adjustment energy to ensure efficient operation

* Adopting high efficient oil separator to ensure that oil fuel consumption is ≤5ppm, ensuring unit with low fuel consumption

* High precision suction and oil filter element

3. Ultra low-temperature screw compressor unit

* Evaporative temperature as low as -55 ℃

4. Intellectualized

* Automatic microcomputer control, run faster, more reliable, more powerful control, has achieved a modular, network, and also has a beautiful appearance, convenient operation, friendly interface, etc

Application

Screw Compressor units widely used in food refrigeration and freezing, dairy, ocean fisheries processing, cold chain, logistics, cold storage, chemical industry, polycrystalline silicon, electronics, aerospace, pharmaceuticals, coal, petroleum, etc. field.

Recommend Products

Hot Searches