- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Reliable

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

15m*2m*1.8m

-

Power (kW):

-

55

-

Weight:

-

4500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic Grade:

-

Fully Automatic

-

Power:

-

37KW

Quick Details

-

Screw Design:

-

Single or Double Screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Reliable

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

15m*2m*1.8m

-

Power (kW):

-

55

-

Weight:

-

4500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic Grade:

-

Fully Automatic

-

Power:

-

37KW

Parameters:

Advantages:

|

PET GRANULATING MACHINE

|

|

|

|

|

||||

|

Model

|

RLB50

|

RLB65

|

RLB75

|

RLB95

|

||||

|

Screw Dia

|

50.5mm

|

62.4mm

|

71.2mm

|

93mm

|

||||

|

L/D

|

32-48mm

|

32-48mm

|

32-48mm

|

32-48mm

|

||||

|

Capacity

|

80-150kg/h

|

150-300kg/h

|

300-550kg/h

|

600-1000kg/h

|

||||

B: Vacuum exhaust or natural exhaust port design can exclude the waste gas and discharging water in the production process, which

can be more stable in extrusion, more dense particles, and guarantee the good quality of the product.

Fiber Reinforcement:

Polymer Blending:

+Polymer Blending: blending of PC/ABS, PA/ABS, PP/EPDM, PA/EPDM, PP/SBS, etc.

+Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE; radiation- crosslink able compounds, optical fiber protection compounds, heat-shrinkable polymer compounds.

+Special Compounds: PPR pipe compounds, PE compounds for cross linked pipes, tobacco filter compounds etc.

+High Concentration Color Master Batches: PE, ABS, PS, EVA, PET, PP etc. with high concentration of pigments and other processing aids.

+Master batches with Flame-Retardants: PP, PA, ABS, EVA, PBT, etc. with flame retardants and other additives.

+Special Functional Master batches: Master batches with anti-static, anti-bacteria, or other special functional fillers.

+Master batches for Degradable Polymers: PP, PE, PS, etc, blended with high concentration of starch and other processing aids.

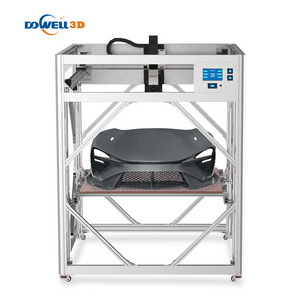

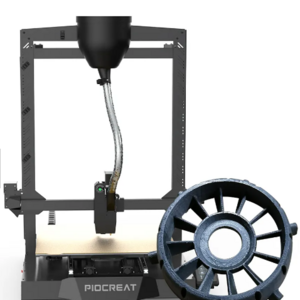

PET Parallel Twin Screw Extruder Pellet Machine

Description & Introduction:

PET pellet machine adopts parallel twin screw extruder, which is special design for waste PET processing; also it can recycle material such as PP, PE, ABS and PS material etc.

Higher homogenization efficiency downstream of filtration and upstream of degassing enhances the subsequent degassing performance and improves the characteristics of melt. According to the character of PET itself, this step is very important and will influence the quality of PET pellets.

We can design different pet plastic pelletizing machine according to your requirements:

a. Equipment name: PET plastic pelletizing machine.

b. Production capacity: 80kg/h~1000kg/h.

c. Material processed: PET flakes to PET granules.

d: You can choose different devices according to your material. You can also purchase separate device based on your own

conditions.

e: We providing turn-key project for you. Design-Product-Installment-Testing.

f. Superiority: Easy operation, high capacity, low energy consumption, safety, reliability, etc.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.