- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Application:

-

Shredding

-

Raw material:

-

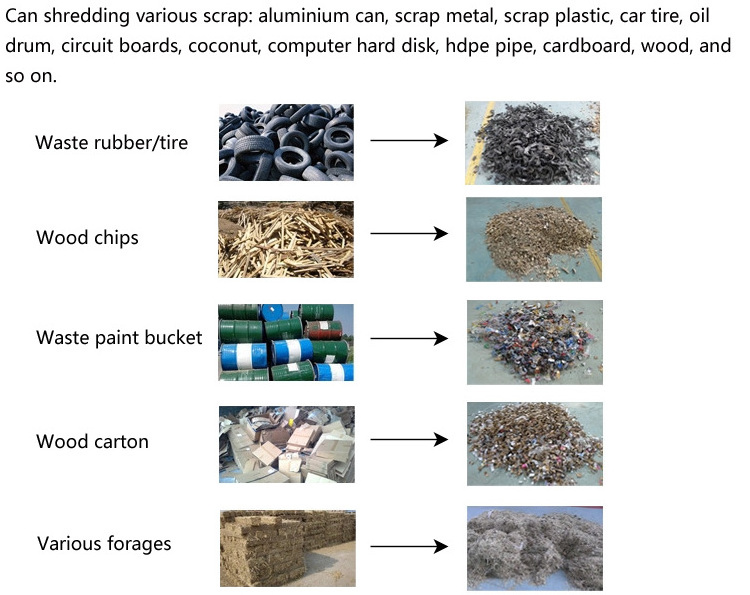

Thin metal , plastic products, kitchen waste, wood, paper, hard disk

-

Final product:

-

2-10cm pieces

-

Advantage:

-

Easy Opperation

-

Shredder Type`:

-

Vertical Shredder

-

After-sales Service Provided:

-

1 year

-

Voltage:

-

customize

-

Color:

-

customize

-

Certification:

-

CE Certificate

-

MOTOR:

-

pure copper motor

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Marketing Type:

-

New Product 2024

-

Power (kW):

-

6

-

Weight (KG):

-

500

-

Application:

-

Shredding

-

Raw material:

-

Thin metal , plastic products, kitchen waste, wood, paper, hard disk

-

Final product:

-

2-10cm pieces

-

Advantage:

-

Easy Opperation

-

Shredder Type`:

-

Vertical Shredder

-

After-sales Service Provided:

-

1 year

-

Voltage:

-

customize

-

Color:

-

customize

-

Certification:

-

CE Certificate

-

MOTOR:

-

pure copper motor

Product Description

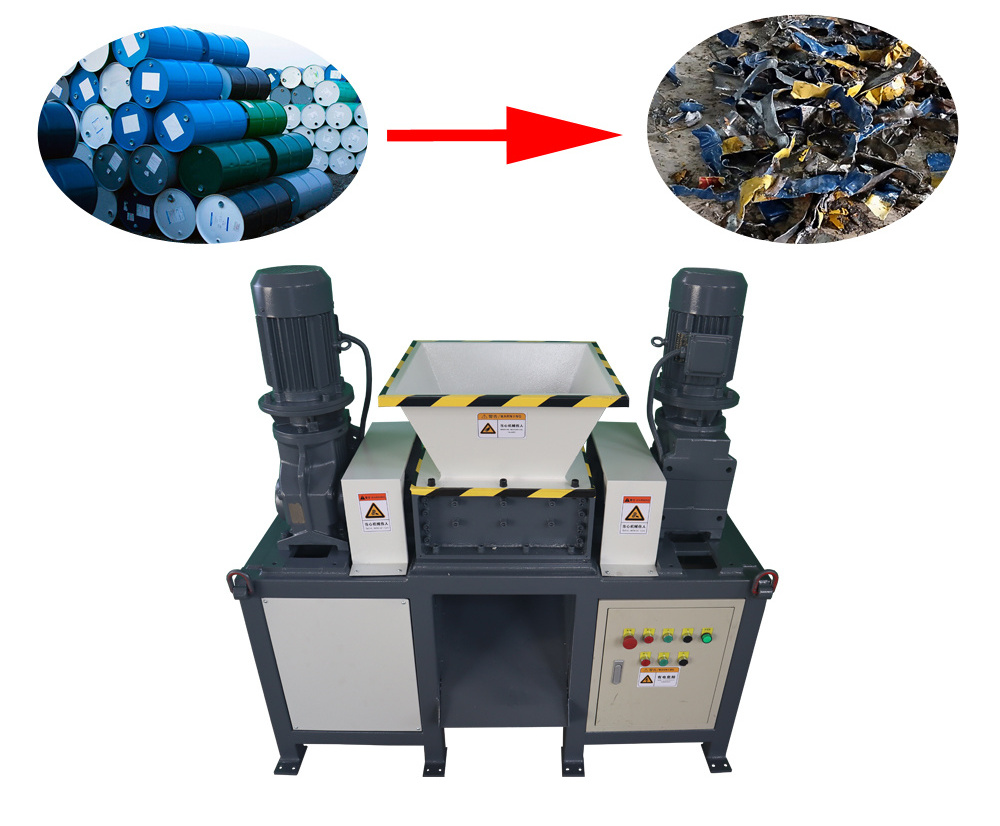

This is a double shaft shredder machine with double electric motor, it can crush cables, hard disk, copper, aluminum, plastic and so on.

Shredding machine product advantages:

1. The blade holder and blade on the rotor can be disassembled for easy cleaning and maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° after wear to continue to use;

3. The main shaft is driven by the gear reduction box, running smoothly, low noise, large torque;

4. Adopt PLC program control system, can automatically reverse, make the machine run stably;

5. The box body is welded and tempered after welding to eliminate the welding stress;

6. The installation position of moving knife is precisely machined by machining center to ensure that the clearance between each moving knife and fixed knife is the same;

7. The moving tool holder is embedded in the tool shaft with high strength screws. On, can prevent welding type after long-term vibration caused by the phenomenon of knife drop.

8. Convenient transportation after tearing, can reduce transportation cost, increase transportation efficiency, convenient secondary processing.

1. The blade holder and blade on the rotor can be disassembled for easy cleaning and maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° after wear to continue to use;

3. The main shaft is driven by the gear reduction box, running smoothly, low noise, large torque;

4. Adopt PLC program control system, can automatically reverse, make the machine run stably;

5. The box body is welded and tempered after welding to eliminate the welding stress;

6. The installation position of moving knife is precisely machined by machining center to ensure that the clearance between each moving knife and fixed knife is the same;

7. The moving tool holder is embedded in the tool shaft with high strength screws. On, can prevent welding type after long-term vibration caused by the phenomenon of knife drop.

8. Convenient transportation after tearing, can reduce transportation cost, increase transportation efficiency, convenient secondary processing.

Structure

Working principle of double shaft shredder:

The double-shaft shredder is sheared by the blades on the two shafts to meet the requirements of shredding materials. The size after shredding is related to the thickness of the shredding blade and the number of teeth. The thinner the blade, the smaller the size of the shredded material, The more the number of cutter teeth, the shorter the length of the shredded material.

Specification

Packaging and Shipping

Customer

Hot Searches