* Fast job changeover

* Multi-type work capabilities

* With integrated bump & turn allows to turn cartons 90º and its alignment

* Extra length crash lock bottom section

* Extra folding & closing section with collapsible central carrier

* Suitable for Straight line, lock bottom, 4 & 6 corner cartons and more

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

11.8*1.3*1.45M

-

Weight:

-

6000 KG

-

Blank size:

-

650/800/1100 mm

-

Name:

-

Fully Automatic Cardboard Folder Gluer Machine

-

Function:

-

Straight line, crash bottom lock, double wall and etc

-

Folding way:

-

Automatic and pressing

-

Glue type:

-

Water-based Cold glue

-

Speed:

-

400m/min

-

Paper material:

-

Cardboard 210-800gsm; A/B/E Flute

-

Certification:

-

CE

-

Way of folding:

-

Fold 1 and fold 3 are 180°and 165°

Quick Details

-

Voltage:

-

3P380v50HZ

-

Place of Origin:

-

Zhejiang, China

-

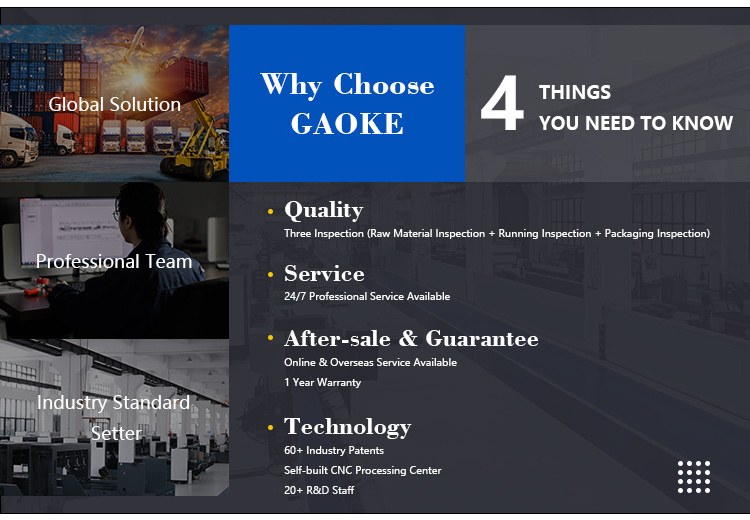

Brand Name:

-

GAOKE

-

Dimension(L*W*H):

-

11.8*1.3*1.45M

-

Weight:

-

6000 KG

-

Blank size:

-

650/800/1100 mm

-

Name:

-

Fully Automatic Cardboard Folder Gluer Machine

-

Function:

-

Straight line, crash bottom lock, double wall and etc

-

Folding way:

-

Automatic and pressing

-

Glue type:

-

Water-based Cold glue

-

Speed:

-

400m/min

-

Paper material:

-

Cardboard 210-800gsm; A/B/E Flute

-

Certification:

-

CE

-

Way of folding:

-

Fold 1 and fold 3 are 180°and 165°

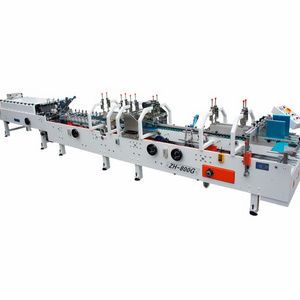

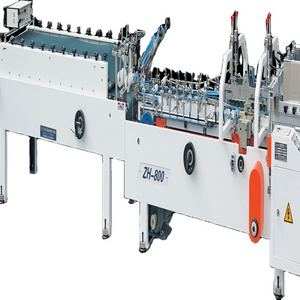

Products Description

Rolam High Speed GS Automatic 4&6 Corner Folder Gluer

Specification

|

Model

|

650

|

800

|

1100

|

||

|

Paper Material

|

Cardboard 210-800 GSM,B/N/E/F Flute

|

|

|

||

|

Max Speed

|

400 M/Min

|

|

|

||

|

Max Thickness of Folded Box

|

12 MM

|

|

|

||

|

Way of Folding

|

Fold 1 and fold 3 are 180°and 135°, fold 2 and fold 4 are 180°

|

|

|

||

|

Power Supply

|

3P 380V 50HZ

|

|

|

||

|

Blank Width

|

650 MM

|

800MM

|

1100MM

|

||

|

Length X Width X Height

|

13 X 1.3 X 1.3M

|

15 X 1.5 X 1.3M

|

15 X 1.8 X 1.3M

|

||

|

Net Weight

|

5.5 T

|

7.5 T

|

8 T

|

||

|

Total Power

|

28.6 KW

|

31.18 KW

|

31.18 KW

|

||

Sample

Details Images

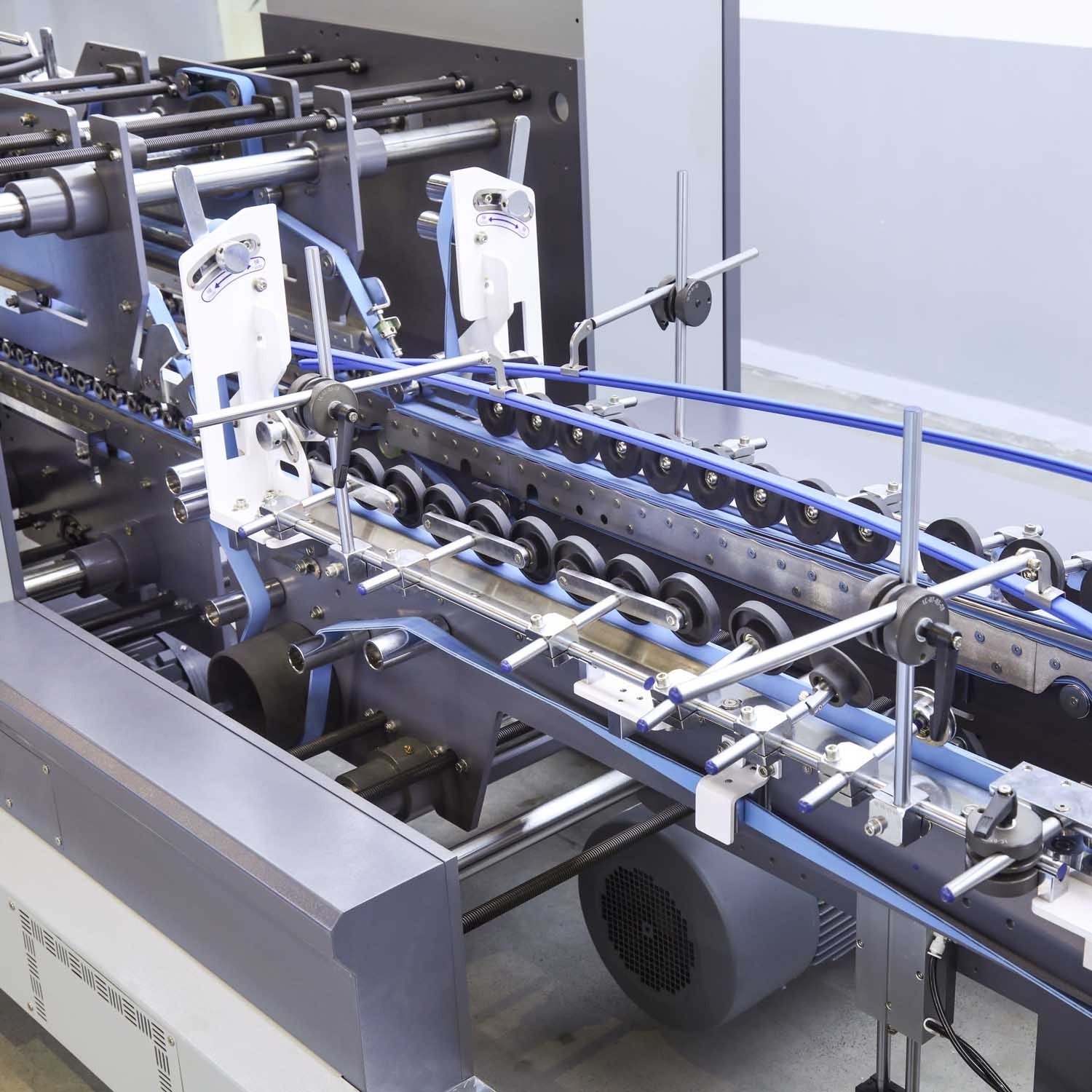

Feeding Section

* Rail width can be horizontally adjusted and set by seven pieces 30mm thickened feeding belt and 10mm metal board.

* Operators can operate feeder switch in any regional.

Pre-folding Section

* Special first folding line pre-fold 180°.

* Third line 165° ,which perfectly meeting the requirements of automatic packaging industry.

Folding and Closing Section

* The Second and fourth folding line 180°.

* Folding and closing section transmit from right and left side ,the belt speed can be adjusted separately and correct the way of

box running to ensure straightly delivery.

* Folding and closing section transmit from right and left side ,the belt speed can be adjusted separately and correct the way of

box running to ensure straightly delivery.

Trombone Section

* Upper and lower belt can be adjusted separately.

* Equipped with photo electronic counting device and kicking paper device, which can press the paper after accounting and make it easy to pack.

* Also equipped with feeding paper inspection device.

* Equipped with photo electronic counting device and kicking paper device, which can press the paper after accounting and make it easy to pack.

* Also equipped with feeding paper inspection device.

Conveyor

* Equipped with special additional sponge belt for the press of boxes valley part.

* Upper section moves back and forward, allowing for different box length.

* Upper section moves back and forward, allowing for different box length.

Hot Searches