- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jiangtai

-

Model Number:

-

Molybdenum Disulfide Grease

-

Product name:

-

Industrial Grease

-

Feature:

-

High Temperature Corrosion

-

Keywords:

-

Graphene grease

-

Use:

-

Heavy Machiney

-

Function:

-

Reduce Friction

-

Appearance:

-

Smooth Ointment

-

Color:

-

Black

-

Packing:

-

Customer Requirements

-

Service:

-

OEM ODM Service

-

Certificate:

-

ISO9001

Quick Details

-

Application:

-

Industrial Lubricant

-

Type:

-

Greases

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jiangtai

-

Model Number:

-

Molybdenum Disulfide Grease

-

Product name:

-

Industrial Grease

-

Feature:

-

High Temperature Corrosion

-

Keywords:

-

Graphene grease

-

Use:

-

Heavy Machiney

-

Function:

-

Reduce Friction

-

Appearance:

-

Smooth Ointment

-

Color:

-

Black

-

Packing:

-

Customer Requirements

-

Service:

-

OEM ODM Service

-

Certificate:

-

ISO9001

High Temperature Polyurea Grease Black Molybdenum Disulfide Grease Industrial Graphite Lubricant Grease

Grease MoS2 are high quality lithium multipurpose and EP greases fortified with micronized molybdenum disulphide for enhanced extreme pressure and anti seize properties. They contain a synergistic blend of additives and performance boosters for optimum performance.

Feathers :

Feathers :

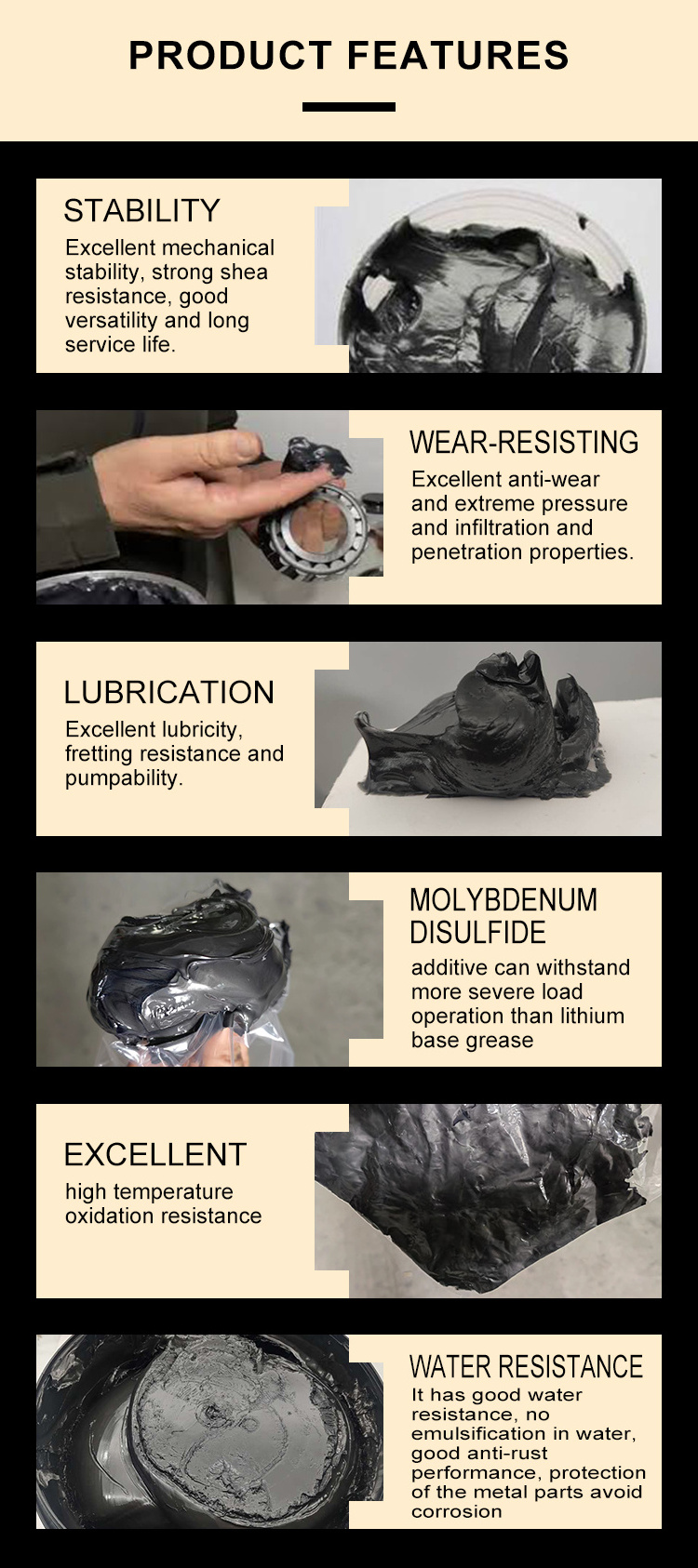

1. Molybdenum disulfide additive can withstand more severe load operation than lithium base grease

2. It has good water resistance, no emulsification in water, good anti-rust performance, protection of the metal parts avoid corrosion

3. Excellent mechanical stability, strong shear resistance, good versatility and long service life.

4. Excellent anti-wear and extreme pressure and infiltration and penetration properties

5. Excellent high temperature oxidation resistance

6. It can completely cover the metal surface and quickly penetrate to the core of the steel wire rope

7. Excellent lubricity, fretting resistance and pumpability.

4. Excellent anti-wear and extreme pressure and infiltration and penetration properties

5. Excellent high temperature oxidation resistance

6. It can completely cover the metal surface and quickly penetrate to the core of the steel wire rope

7. Excellent lubricity, fretting resistance and pumpability.

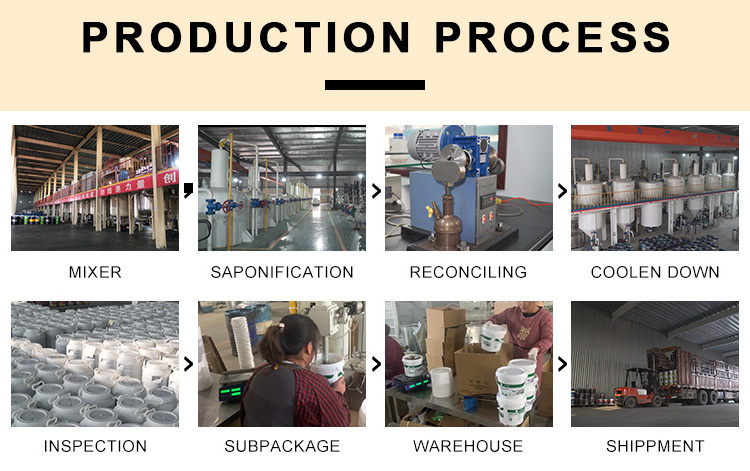

Grease Usage Notice:

1. Position the grease in a ventilated, favorable temperature room. Protected it from dust and impurities after open, close the

drum lid after using.

2. Cleaning the parts of lubrication before using, don’t mix using with other grease. If there is a little oil impregnate, blend

it before using.

1. Position the grease in a ventilated, favorable temperature room. Protected it from dust and impurities after open, close the

drum lid after using.

2. Cleaning the parts of lubrication before using, don’t mix using with other grease. If there is a little oil impregnate, blend

it before using.

Specification

|

Items

|

speciation

|

Test Methods

|

|

Worked Cone Penetration, 0.1mm

|

230

|

GB/T 269

|

|

Drop Point, ℃

|

>180

|

GB/T 4929

|

|

Steel Mesh Oil Separation(100℃, 24h),%

|

1.5

|

GB/T 0324

|

|

NLGI

|

3

|

|

|

Operate Temp

|

-20~140

|

|

Product Features

Production Process

Related Products

Hot Searches