- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V,50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Uboray

-

Weight:

-

650 KG

-

Type of machines:

-

powder filling machine

-

Filling speed:

-

30-50 bottles/min (customizable)

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V,50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Uboray

-

Weight:

-

650 KG

-

Type of machines:

-

powder filling machine

-

Filling speed:

-

30-50 bottles/min (customizable)

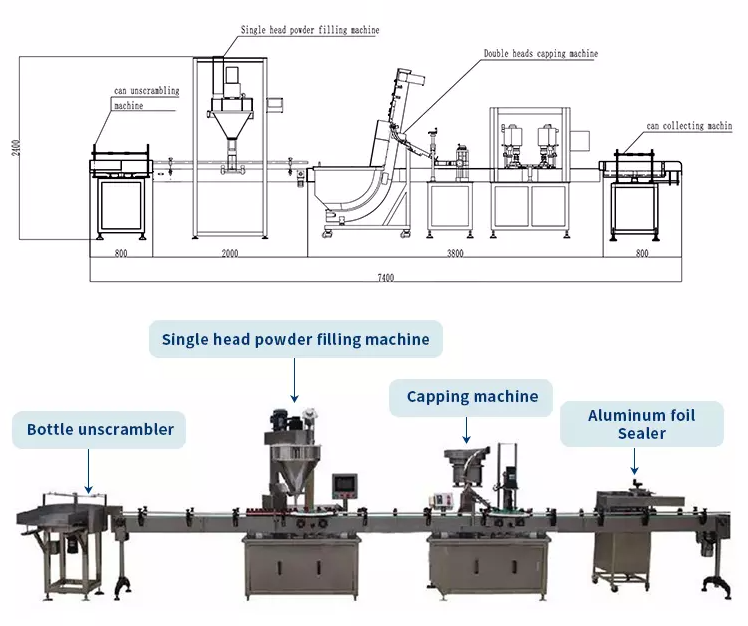

Automatic powder filling machine

The machine can complete the measurement, filling ,capping and labeling.The whole machine is made of stainless steel, anti-corrosion; PLC touch screen man-machine interface, Chinese and English display, For dusty material packaging, Through the replacement of screw attachments, powder materials can be packaged in various packaging specifications such as milk powder, coffee, flour,spice ,pesticides,ect.

The machine can complete the measurement, filling ,capping and labeling.The whole machine is made of stainless steel, anti-corrosion; PLC touch screen man-machine interface, Chinese and English display, For dusty material packaging, Through the replacement of screw attachments, powder materials can be packaged in various packaging specifications such as milk powder, coffee, flour,spice ,pesticides,ect.

Machine Features

1.The entire machine is made of stainless steel, and it is especially suitable for GMP certification, food hygiene certification, and anti-corrosion chemical products.

2.Touch screen man-machine interface,operation is stable.The weight of the package can be adjusted steplessly at any time, and the working status can be changed at any time.

3.Filling adopts servo motor,with the advantages of accurate positioning, high precision, high speed, large torque, long life,speed can be set, good stability and so on.

4.Stirring uses Taiwan geared motor: low noise, long life, and lifetime maintenance free.

5.Designed as feedback proportion tracking system, it overcomes the disadvantages of weight changes due to changes in the proportion of materials.

6.The fully sealed air-resistance glass stainless steel side-opening compound material hopper provides clear visibility of materials and dust without leaking. The suction device is installed at the outlet to protect the workshop environment.

7. Replacement screw accessories can adapt to a variety of materials from ultra-fine powder to large particles.

1.The entire machine is made of stainless steel, and it is especially suitable for GMP certification, food hygiene certification, and anti-corrosion chemical products.

2.Touch screen man-machine interface,operation is stable.The weight of the package can be adjusted steplessly at any time, and the working status can be changed at any time.

3.Filling adopts servo motor,with the advantages of accurate positioning, high precision, high speed, large torque, long life,speed can be set, good stability and so on.

4.Stirring uses Taiwan geared motor: low noise, long life, and lifetime maintenance free.

5.Designed as feedback proportion tracking system, it overcomes the disadvantages of weight changes due to changes in the proportion of materials.

6.The fully sealed air-resistance glass stainless steel side-opening compound material hopper provides clear visibility of materials and dust without leaking. The suction device is installed at the outlet to protect the workshop environment.

7. Replacement screw accessories can adapt to a variety of materials from ultra-fine powder to large particles.

|

Automatic Powder Weighing Filling Capping And Labeling Machine

|

|

|

|

|

||||

|

Model

|

UBY-80

|

UB-520

|

UB-620

|

UB-720

|

||||

|

Filling Weight

|

10-5000g(customizable)

|

Max.520mm

|

Max.620mm

|

Max.720mm

|

||||

|

Bottle diameter

|

Φ30-Φ140mm(customizable)

|

80-400mm

|

80-500mm

|

80-600mm

|

||||

|

Bottle height

|

50mm-200mm(customizable)

|

70-250 mm

|

60-300 mm

|

200-350 mm

|

||||

|

Power

|

220V/380V/50/60 HZ

|

|

|

|

||||

|

Packing speed

|

30-70bottle/min

|

|

|

|

||||

|

Measurement accuracy

|

≤500g,≤±1%;>500g,≤±0.5% (Varies due to the characteristics of the material)

|

|

|

|

||||

|

Powder

|

2.5KW

|

2.2KW

|

3.0KW

|

4.0KW

|

||||

|

Machine Weight

|

750KG

|

480KG

|

550KG

|

690KG

|

||||

|

Dimensions (mm)

|

4400*1.2*1800(L*W*H mm)

|

1500*1600*1800

|

1600*1700*1800

|

1600*1700*1800

|

||||

Description Of Main Packaging Process:

①Bottle Unscrambler → ② Automatic Powder Weighting And Filling Machine → ③Automatic Capping Machine → ④Automatic Labeling Machine

①Bottle Unscrambler → ② Automatic Powder Weighting And Filling Machine → ③Automatic Capping Machine → ④Automatic Labeling Machine

Hot Searches