- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1500x1100x2250mm

-

Motor Power (kW):

-

3

-

Model Number:

-

J23-40T

-

Weight (T):

-

2.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Power Press Machine

-

Application:

-

Metal Sheet Stamping

-

Material:

-

Steel Material

-

Color:

-

Optional Color

-

Advantage:

-

High Efficiceny

-

Nominal Force (kN):

-

400kN

Quick Details

-

Slide Stroke (mm):

-

50

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

BLMA

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1500x1100x2250mm

-

Motor Power (kW):

-

3

-

Model Number:

-

J23-40T

-

Weight (T):

-

2.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Power Press Machine

-

Application:

-

Metal Sheet Stamping

-

Material:

-

Steel Material

-

Color:

-

Optional Color

-

Advantage:

-

High Efficiceny

-

Nominal Force (kN):

-

400kN

Product Overview

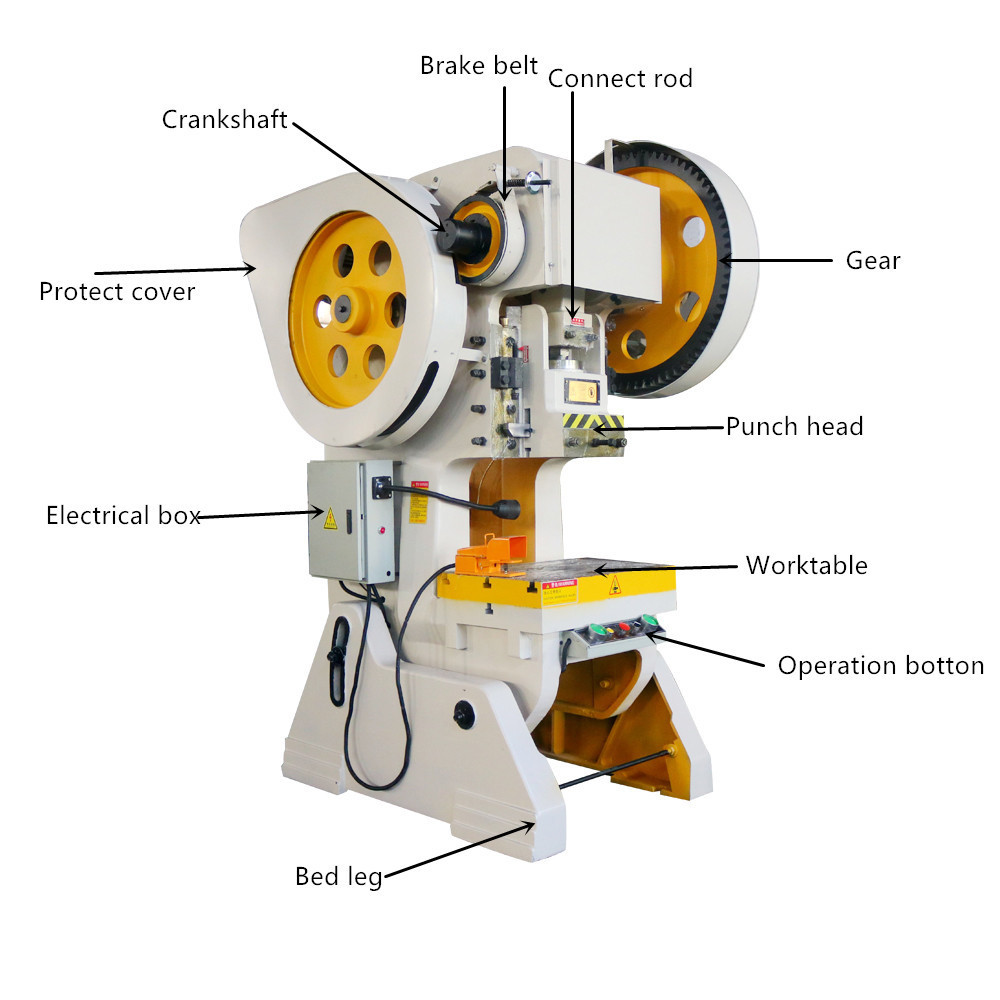

Punching machine

The press is applicable to compression of plastic materials. For example, powder and plastic products forming and heat/cool metal extruction, stamping, bending, edge-folding, straightening, depressed mounting and etc.

Independent drive structures and electrical devices insure reliable operation with centered control buttons. Adjustment ,manual operation and semi-automatic operation, three modes are provided respectively for your choice.

The working pressure, pressing speed, unload-descending speed and decelecrated pressing speed can be respectively adjusted in requirements. By preset, knock-out and drawing can be taken out with pressure-dependent or distance-dependent of die. .

Independent drive structures and electrical devices insure reliable operation with centered control buttons. Adjustment ,manual operation and semi-automatic operation, three modes are provided respectively for your choice.

The working pressure, pressing speed, unload-descending speed and decelecrated pressing speed can be respectively adjusted in requirements. By preset, knock-out and drawing can be taken out with pressure-dependent or distance-dependent of die. .

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

Item

|

J23-10T

|

J23-16T

|

J23-25T

|

J23-40T

|

J23-63T

|

J23-80T

|

J23-100T

|

J23-125T

|

|

Nominal Pressure

|

100KN

|

160KN

|

250KN

|

400KN

|

630KN

|

800KN

|

1000KN

|

1250KN

|

|

Slide stroke (Times/min)

|

145

|

140

|

70

|

55

|

50

|

45

|

45

|

38

|

|

Slide strokes

|

50mm

|

60mm

|

70mm

|

100mm

|

110mm

|

115mm

|

130mm

|

150mm

|

|

Max closing height

|

150mm

|

170mm

|

200mm

|

300mm

|

330mm

|

380mm

|

380mm

|

500mm

|

|

Die height adjustment

|

40mm

|

40mm

|

40mm

|

70mm

|

80mm

|

80mm

|

100mm

|

100mm

|

|

Distance between slider center and machine

|

130mm

|

160mm

|

180mm

|

215mm

|

230mm

|

250mm

|

280mm

|

390mm

|

|

Workbench diameter(mm)

|

240x360

|

300x480

|

320x525

|

400x650

|

440x700

|

480x750

|

540x840

|

720x1100

|

|

Pole distance

|

180mm

|

220mm

|

240mm

|

300mm

|

300mm

|

300mm

|

380mm

|

550mm

|

|

Shank hole diameter

|

30mm

|

35mm

|

40mm

|

50mm

|

60mm

|

60mm

|

60mm

|

60mm

|

|

Shank hole depth

|

50mm

|

60mm

|

60mm

|

70mm

|

70mm

|

80mm

|

80mm

|

75mm

|

|

Pad thickness

|

50mm

|

50mm

|

50mm

|

75mm

|

80mm

|

95mm

|

100mm

|

130mm

|

|

Body tilting angle

|

30°

|

20°

|

20°

|

20°

|

20°

|

20°

|

20°

|

13°

|

|

Motor power

|

1.5Kw

|

1.5KW

|

2.2KW

|

3KW

|

4KW

|

7.5KW

|

7.5KW

|

11Kw

|

|

Weight

|

450Kg

|

750KG

|

1500KG

|

2500KG

|

4000KG

|

5000KG

|

6000KG

|

7000Kg

|

PRODUCT CONFIGURATION

Packaging and Delivery

Related Products

Hot Searches