- Product Details

- {{item.text}}

Quick Details

-

Application:

-

forklift attachment

-

Service:

-

OEM Customized Services

-

Color:

-

Customized Color

-

Used for:

-

Forklift Body Parts

-

After Warranty Service:

-

provide repair parts

-

Quality:

-

High-Quality

-

Packing:

-

Wooden Case

-

Usage:

-

forklift belongings

-

Product name:

-

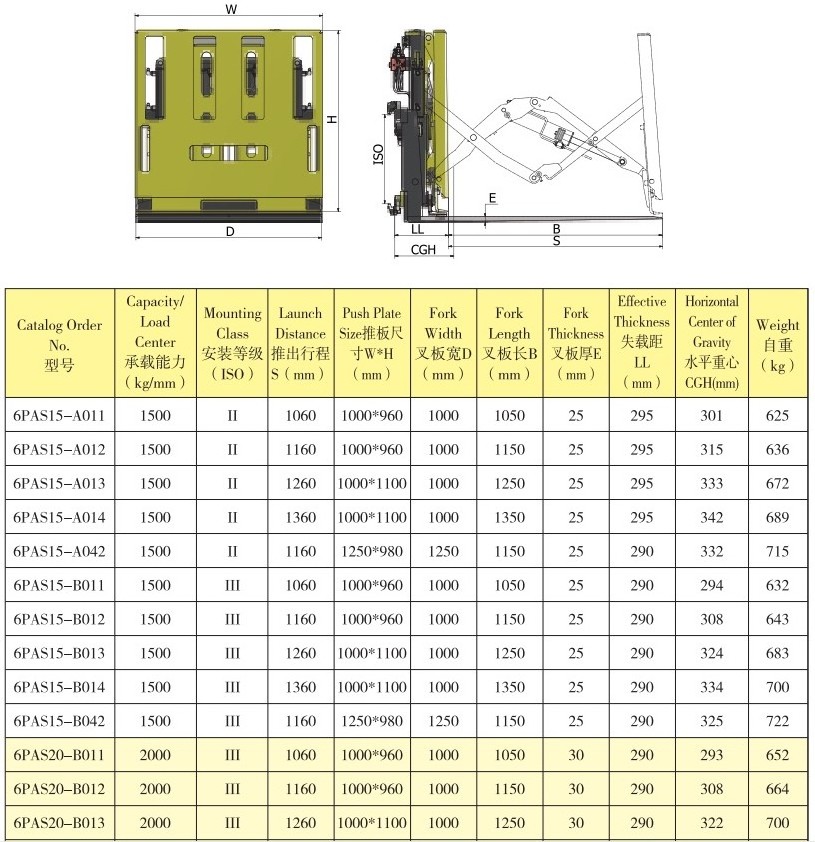

push pull clamp

-

OEM:

-

Accept OEM

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

775

-

Place of Origin:

-

Fujian, China

-

Application:

-

forklift attachment

-

Service:

-

OEM Customized Services

-

Color:

-

Customized Color

-

Used for:

-

Forklift Body Parts

-

After Warranty Service:

-

provide repair parts

-

Quality:

-

High-Quality

-

Packing:

-

Wooden Case

-

Usage:

-

forklift belongings

-

Product name:

-

push pull clamp

-

OEM:

-

Accept OEM

Details Images

Products Description

Push-pull clamps are hydraulic attachments used for handling loads without pallets. A flat faceplate and gripper secure the load,

and the attachment can extend forward and retract, effectively “pushing” and “pulling” the load. This attachment is ideal for

handling goods shipped on slip sheets rather than pallets.

|

Delivery time

|

within 15 days

|

Condition

|

100%New from factory production line

|

|

Delivery method

|

BY SEA, BY AIR

|

Customized

|

support customized product

|

|

Packing

|

carton/wooden case/pallet

|

Quality

|

High Quality

|

|

Availability

|

Production stand by

|

After Sales

|

Provide online technical support

|

More Products

Factory Profile

Product packaging

FAQ

Which Forklift Attachment Do I Need?

To ascertain the appropriate forklift attachment for a task, it’s essential to evaluate several factors, including the nature of the job, the load’s weight and height, and the workplace environment. Safety considerations should be central to your decision-making process.

Nature Of The Task And Workspace:

The type of material being moved and the workspace characteristics are primary determinants of which forklift attachment is required. For example:

* Carpet Poles are ideal for transporting rolls of carpet or fabric and are particularly useful in carpet warehouses or home improvement stores.

* Paper Roll Clamps: Best suited for handling large rolls of paper, making them essential for paper mills and printing facilities.

* Cylinder Caddies: Specifically designed for transporting gas cylinders, useful in manufacturing facilities or places dealing with gases.

* Side Shifters: Highly beneficial in confined spaces as they allow horizontal movement of the load without moving the forklift, which is crucial for precise placement in storage racks or tight spaces.

Load Weight:

Assessing the weight of the load is vital to ensure the forklift’s capacity isn’t exceeded. Overloading a forklift can cause it to tip over. When using an attachment, it’s important to note that it adds weight and can change the forklift’s load centre. To maintain stability:

* Ensure that the combined weight of the attachment and the load does not exceed the forklift’s rated capacity.

* Keep the load as low as possible to maintain a low centre of gravity.

Load Height:

Evaluating how high the load needs to be lifted is critical. Attachments like mast extenders can help lift loads to greater heights, but ensuring that the forklift’s lifting capacity aligns with the height requirements is important. Raising the mast too high can make the forklift unstable. Key considerations include:

* Ensure not to extend the mast beyond the forklift’s safe lifting capacity.

* Being cautious of the surrounding environment, such as low ceilings or overhead obstacles.

Safety Considerations:

Safety is paramount; choosing the right attachment is critical in ensuring a safe working environment. Attachments should be compatible with the forklift, and operators should be trained. Additionally, regular inspections and maintenance of attachments are essential to ensure they are in good working condition.

To ascertain the appropriate forklift attachment for a task, it’s essential to evaluate several factors, including the nature of the job, the load’s weight and height, and the workplace environment. Safety considerations should be central to your decision-making process.

Nature Of The Task And Workspace:

The type of material being moved and the workspace characteristics are primary determinants of which forklift attachment is required. For example:

* Carpet Poles are ideal for transporting rolls of carpet or fabric and are particularly useful in carpet warehouses or home improvement stores.

* Paper Roll Clamps: Best suited for handling large rolls of paper, making them essential for paper mills and printing facilities.

* Cylinder Caddies: Specifically designed for transporting gas cylinders, useful in manufacturing facilities or places dealing with gases.

* Side Shifters: Highly beneficial in confined spaces as they allow horizontal movement of the load without moving the forklift, which is crucial for precise placement in storage racks or tight spaces.

Load Weight:

Assessing the weight of the load is vital to ensure the forklift’s capacity isn’t exceeded. Overloading a forklift can cause it to tip over. When using an attachment, it’s important to note that it adds weight and can change the forklift’s load centre. To maintain stability:

* Ensure that the combined weight of the attachment and the load does not exceed the forklift’s rated capacity.

* Keep the load as low as possible to maintain a low centre of gravity.

Load Height:

Evaluating how high the load needs to be lifted is critical. Attachments like mast extenders can help lift loads to greater heights, but ensuring that the forklift’s lifting capacity aligns with the height requirements is important. Raising the mast too high can make the forklift unstable. Key considerations include:

* Ensure not to extend the mast beyond the forklift’s safe lifting capacity.

* Being cautious of the surrounding environment, such as low ceilings or overhead obstacles.

Safety Considerations:

Safety is paramount; choosing the right attachment is critical in ensuring a safe working environment. Attachments should be compatible with the forklift, and operators should be trained. Additionally, regular inspections and maintenance of attachments are essential to ensure they are in good working condition.

Hot Searches