- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

TXSL

-

Power (kW):

-

5.5

-

Weight (KG):

-

2500

Quick Details

-

Max.Shrinking Capacity (Thickness)(mm):

-

5 mm

-

Marketing Type:

-

New product

-

Max.Shrinking Capacity (Diameter)(mm):

-

50 mm

-

Place of Origin:

-

China

-

Brand Name:

-

TXSL

-

Power (kW):

-

5.5

-

Weight (KG):

-

2500

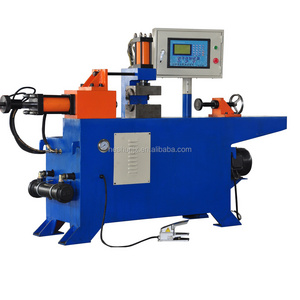

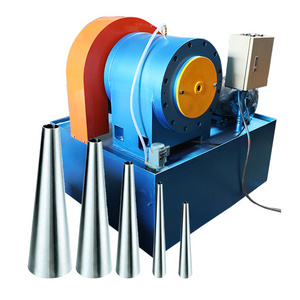

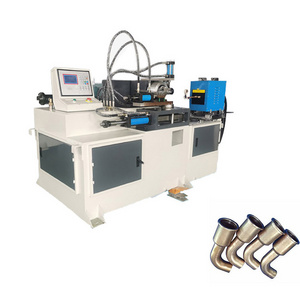

Description of Steel Pointed Pipe End Forming Machine Rebar Reducing Machine

1. High efficiency: rapid forming, smooth machining surface, no scars on the workpiece. One worker can finish the work of taper pipes which are needed for a construction site.

2. Small size, light weight, low noise, easy operation, three-phase and single-phase voltage optional.

3.Easy maintenance,low failure rate ,beautiful appearance,compact structure.The mold and the mold seat are sliding to draw, the dovetail mold is convenient for loading and unloading.

4. Non-polluting.

Parameters of Steel Pointed Pipe End Forming Machine Rebar Reducing Machine

|

System Name |

Main Technical Parameters and Configuraton |

|

|

General Specification |

Structure Type

|

Machnical and automatic |

|

Manufacturing Technique

|

Finish Machining

|

|

|

Control System |

Electrical component brand |

Chint |

|

Control system |

Electric |

|

|

Circulation lubrication system |

Power pump brand |

Shanghai,Dongfang |

|

Power pump parameters |

0.25kw |

|

|

High frequency heating system |

Transformer Parameters |

|

|

Frequency conversion furnace (KW) |

50 |

|

|

Heating time(s/piece) |

15 |

|

|

General Performance |

Max. processing diameter (mm) |

50 |

|

Machinging Taper (mm) |

100-200 |

|

|

Diemension (mm) |

2600*800*1200 |

|

|

Weight (KG) |

1200 |

|

Photos of Steel Pointed Pipe End Forming Machine Rebar Reducing Machine

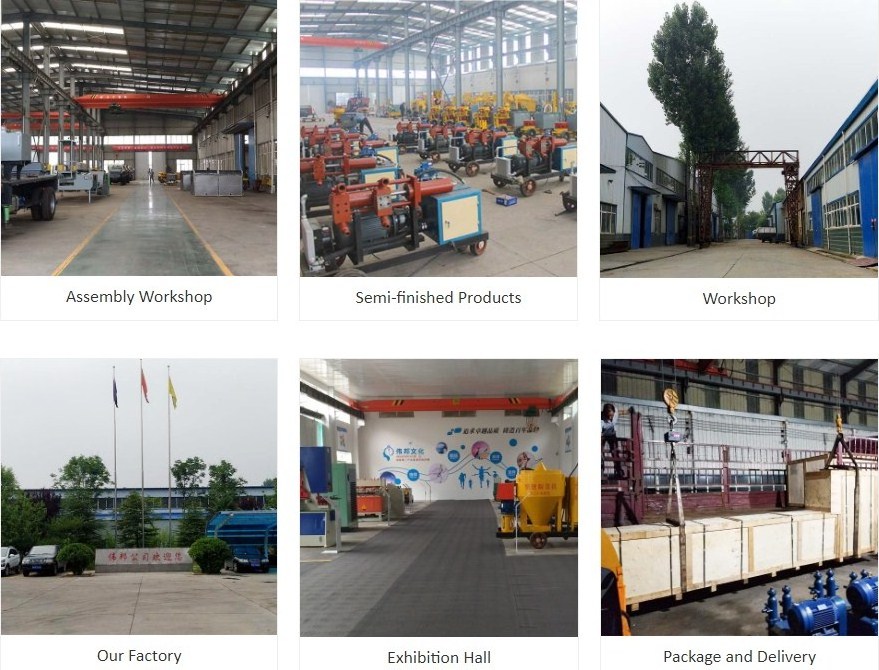

Introduction of our company

Henan Weibang Intelligent Technology Co., Ltd

is located in Zhengzhou High-tech district, Henan Province, China. Manufacturing base is located in Jiaozuo High-tech district.

The company with registered capital of RMB 31 million and workshop area of 60,000 square meters is divided into

five departments

(management department, R&D department, procurement department, production department, sales department)

and three centers

(

after-sales service center, testing center, and finished product display center.)

In order to improve product quality and customer satisfaction, an experimental base has been set up to test equipment performance and provide training for equipment operator.

We adhere to the principle of

integrity management and mutual benefits

and

customer’s satisfaction is our eternal pursue

. Since its establishment in 2002, the company has developed into a high-end equipment manufacturer. By now we have established several subsidiary companies in Guizhou, Shenzhen and Changsha cities, over 70 sales offices and 38 first-level agents in the world.

The company has paid much attention to research and innovation and has established long-term cooperation relationships with China Construction Machinery Research Institute, Henan Polytechnic University and other universities and scientific research institute. We have obtained 33 utility model patent certificates, mine product safety sign certificates, and ISO quality management system certificate. Now the company has made an international development strategy. We are make unremitting efforts to make our product popular all over the world.

Machines of our company:

Our main business include: shotcrete manipulators, automatic feeding shotcrete machines, all-in-one of mortar mixing and grouting machines, small and medium size concrete spraying machines, grouting machines, cement grout pumps, removable dedusting water mist cannon sprayers, rebar bending machines, rock drills, welding machine etc, which are widely used in mining, railway, highway, tunneling, subway, slope and hydro-power engineers.