- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QINTAO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6750x1880x2540

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

13500 kg

-

Product Name:

-

JKY45/45D-35 Double shaft mixer

-

Types of materials:

-

Clay, shale, gangue, cinder

-

Stirring shaft:

-

Heat treatment

-

Mixing blade material:

-

Nodular cast iron

-

gear:

-

Heat treated hard gear

-

Add water way:

-

Adjust the control

-

Mixing way:

-

Compulsory mixing

-

Way to work:

-

Continuous operation

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

-

Brick Raw Material:

-

Clay, shale, coal gangue, fly ash

-

Production Capacity (Pieces/8 hours):

-

80000-105000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QINTAO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6750x1880x2540

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

13500 kg

-

Product Name:

-

JKY45/45D-35 Double shaft mixer

-

Types of materials:

-

Clay, shale, gangue, cinder

-

Stirring shaft:

-

Heat treatment

-

Mixing blade material:

-

Nodular cast iron

-

gear:

-

Heat treated hard gear

-

Add water way:

-

Adjust the control

-

Mixing way:

-

Compulsory mixing

-

Way to work:

-

Continuous operation

Product Description

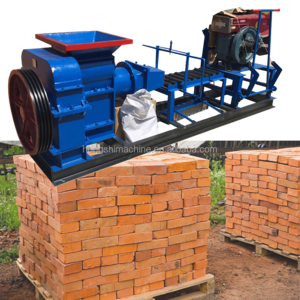

JKB45/45D-35 Vacuum brick making machine

The reamer adopts wear-resistant metal spraying technology. The key parts, such as the stirring shaft, the reamer spindle and the fuselage, are treated by aging, tempering and quenching.Reducer gears are all hard tooth surfaces.

Brick raw material specifications:

Annealing and mechanical processing

The fuselage is an important part of the brick-making machine. All the important parts of our company should be fired in the furnace after welding, so as to eliminate the internal stress of material production due to welding, so that the parts of the equipment will not appear cracks and other defects due to their own reasons in the process of use. Our company has CNC horizontal longmen milling machine, vertical lathe and other advanced processing equipment, processing

quality can be guaranteed, so that the product installation accuracy further improve!

The fuselage is an important part of the brick-making machine. All the important parts of our company should be fired in the furnace after welding, so as to eliminate the internal stress of material production due to welding, so that the parts of the equipment will not appear cracks and other defects due to their own reasons in the process of use. Our company has CNC horizontal longmen milling machine, vertical lathe and other advanced processing equipment, processing

quality can be guaranteed, so that the product installation accuracy further improve!

Product quality control

Advanced high-precision processing equipment is the premise to ensure product quality, the company has CNC boring machine, CNC drilling machine, gantry milling machine and other processing equipment; The company always puts product quality in the first place, all parts have to go through layers of inspection before entering the next process, in strict accordance with the quality management system requirements, product parts for self-inspection, mutual inspection and special inspection of the quality inspection procedures, to ensure that all parts are qualified products.

Advanced high-precision processing equipment is the premise to ensure product quality, the company has CNC boring machine, CNC drilling machine, gantry milling machine and other processing equipment; The company always puts product quality in the first place, all parts have to go through layers of inspection before entering the next process, in strict accordance with the quality management system requirements, product parts for self-inspection, mutual inspection and special inspection of the quality inspection procedures, to ensure that all parts are qualified products.

The parts of JKY series vacuum brick machine, such as clay board and mud cutter, are cast with wear-resisting material. At the same time, the screws and nuts are designed to be on the non-stress surface to reduce wear and easy to disassemble.

The company has a spare parts library, equipped with all conventional models of parts, can provide users with timely parts services.

The reamer is composed of a sleeve and a spiral blade. The sleeve is a thick-walled seamless steel pipe. The blade is made of a wear-resistant steel plate in accordance with the specified size and is assembled and welded by workers. After the completion of the welding, the surface of the wear-resistant metal material should be sprayed. Compared with the casting reamer, the biggest advantage is that it can be repaired, when the wring also appears wear, remove the wearable electrode for surfacing to reach the size, can continue to use.

Specification

|

item

|

value

|

|

Applicable Industries

|

Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

|

|

Condition

|

New

|

|

Type

|

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

|

|

Brick Raw Material

|

Clay, shale, coal gangue, fly ash

|

|

Processing

|

Brick Production Line

|

|

Stirring shaft

|

Heat treatment

|

|

Mixing blade material

|

Nodular cast iron

|

|

gear

|

Heat treated hard gear

|

|

Add water way

|

Adjust the control

|

|

Mixing way

|

Compulsory mixing

|

|

Way to work

|

Continuous operation

|

Packing & Delivery

Container// sea worthy packaging

Hot Searches