- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ocean lucky

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Power:

-

24kw

-

Dimension(L*W*H):

-

1200*800*1500mm

-

Weight:

-

95kg

-

Machinery Capacity:

-

70kg

-

Machinery Function:

-

steamed

-

Product name:

-

Full-automatic Intelligent Cooking Machine

-

Application:

-

Restaurant Canteen

-

Usage:

-

Home Hotel Restaurant Cooking

-

Type:

-

Cooking Equipment

-

Power Source:

-

220V SINGLE PHASE

-

Material:

-

304 Stainless Steel

-

Heating Way:

-

Electricity Heating

-

Feature:

-

Non- Fingerprint

-

Capacity:

-

71L

-

Style:

-

Modern Desgin

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

New Product 2023

-

Model Number:

-

ZY-ZG014

-

Brand Name:

-

ocean lucky

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Power:

-

24kw

-

Dimension(L*W*H):

-

1200*800*1500mm

-

Weight:

-

95kg

-

Machinery Capacity:

-

70kg

-

Machinery Function:

-

steamed

-

Product name:

-

Full-automatic Intelligent Cooking Machine

-

Application:

-

Restaurant Canteen

-

Usage:

-

Home Hotel Restaurant Cooking

-

Type:

-

Cooking Equipment

-

Power Source:

-

220V SINGLE PHASE

-

Material:

-

304 Stainless Steel

-

Heating Way:

-

Electricity Heating

-

Feature:

-

Non- Fingerprint

-

Capacity:

-

71L

-

Style:

-

Modern Desgin

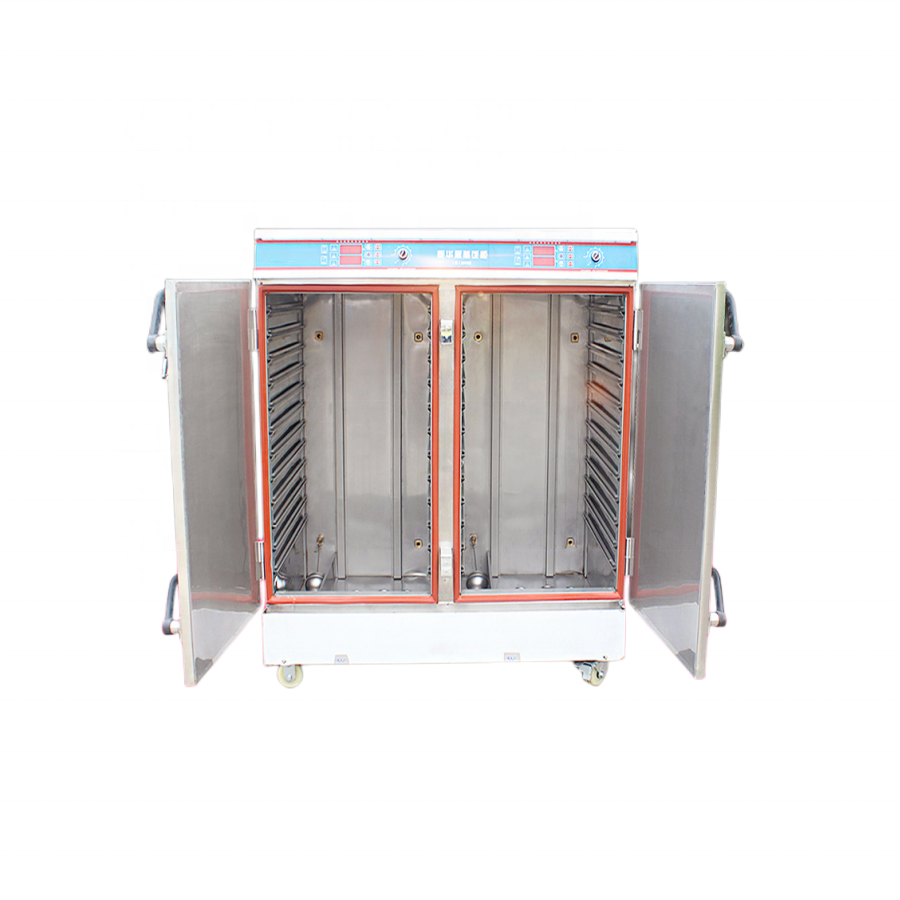

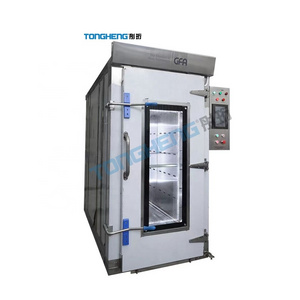

Product parameter

| model | ZY-ZG014 |

| Heating mode | Electric heating |

| Rated power | 24kw |

| voltage | 380V |

| weight | 95kg |

| Productive capacity | 60-75kg⁄times |

| Overall dimension | 1200*800*1500mm |

| Scope of application | Steamed rice steamed bread steamed vegetables, stew soup, brewing, sterilization, disinfection |

Operating steps for using an electric steam cabinet:

1. Preheating: When using electric heating to steam food, the water tank can be filled with water and then powered on for preheating. After the water in the tank boils and generates steam, the food can be steamed.

2. Steamed food: Before opening the door to steam food, the power or steam valve should be turned off, and the door lock should be slowly opened to allow the high-temperature steam inside the steam cabinet to relieve pressure to prevent steam burns. After pressure relief, the cabinet door can be opened to place the food to be steamed, and the door handle can be closed to power on and allow the steam cabinet to heat up.

3. Pressure relief and extraction: After the steamed food is cooked, the power or steam valve can be turned off, and whether to remove it immediately depends on whether the steamed food needs to be stewed. When opening the door, be careful not to face the steam cabinet or the crack in the door, and try to stay away from the steam cabinet as much as possible. Slowly open the door lock and let the high-temperature steam inside the steam cabinet relieve pressure before taking out the food. When removing food, insulated gloves should be worn to prevent hands from getting burned.

Precautions and maintenance instructions:

1. Door handle: When opening the door, the handle should be pulled 900 degrees from bottom to top. When closing the door, the handle should be pulled 900 degrees from top to bottom to the locked position. Please reverse the operation.

2. Pressure relief valve: A pressure relief port is installed on the lower right side of this steam cabinet, which is a discharge channel for excess steam and exhaust gas. It is important not to block it, and it is not recommended to use external pipelines for outdoor discharge. Installing pipelines may cause condensation water blockage or ice blockage at the outdoor exhaust port in winter due to improper connection, resulting in accidents.

3. Float valve: Its function is to automatically feed water. It should be noted that the water valve connected to the steam tank is in a normally open state. The float valve should be frequently pressed down to observe whether the incoming water pressure and flow rate are normal and unobstructed, especially when newly installed water pipes are often blocked by dirt and scaling at the inlet hole of the float valve in hard water areas. If problems are found, they should be dealt with promptly to avoid water shortage.

4. Attention should be paid to external steam: This steam cabinet is not a high-pressure sealed container, and attention should be paid to adjusting the steam input pressure during use. It is not allowed to use it under excessive pressure.

5. After using the steam cabinet for a period of time, there may be air leakage from the door gap, and slight air leakage is a normal phenomenon. Please rest assured to use it. You can loosen the installation and fixing screws of the door or lock seat by yourself, and adjust the gap between the door and the cabinet to solve the problem.

6. Daily discharge of bottom water and regular descaling: When using electric heating, the drain valve at the front and bottom of the steam cabinet should be opened after each day's work is completed to discharge the bottom water. Due to the evaporation of clean water into steam during food steaming, impurities will continue to remain in the water and accumulate on the electric heating pipe and float valve, which can cause dry burning of the electric heating pipe and blockage of the float valve. If scaling occurs, a 5% citric acid solution can be injected into the water tank, heated and boiled for 15 minutes, soaked for 1 hour, and then boiled for another 15 minutes to remove the scale, remove the sewage, and inject clean water several times.

7. It is normal for the visible steam cabinet to have a small amount of water droplets on the visible window during use, which can achieve visual effects.

8. When opening the door, pay attention to steam: When steam leaks out of the door, avoid it to prevent burns.

9. Do not use a water spray pipe to clean this equipment. Water will conduct electricity to prevent splashing and wetting the electrical parts, which may cause leakage accidents.

10. After each work is completed, the power supply of the steam cabinet must be cut off or the main steam inlet valve should be closed when using steam heating.

11. If the power cord ages due to damage, it must be discontinued and replaced with a power supply of the same specification and model, or contact the supplier.

12. The casing of this machine must be properly grounded to ensure safety

Zhengzhou Yangyun Import and Export Co., Ltd., backed by Zhengzhou Yangyun Machinery Equipment Co., Ltd., is a comprehensive trade service company that integrates domestic and foreign trade, technical support, and export services. Its business scope includes the import and export of various types of mechanical equipment such as food machinery, packaging machinery, woodworking machinery, and construction industry machinery, as well as product installation, debugging Integrated technical support for maintenance, covering more than 50 countries and regions including Europe, South America, the Middle East, South Asia, and Africa. We have established long-term cooperative relationships with over 600 enterprises and individuals.

The company has a professional, dedicated, and comprehensive service team, advanced enterprise management model, systematic product service process, and patient and thoughtful after-sales service, which have won the unanimous trust of domestic and foreign customers and friends. The company adheres to the business philosophy of "integrity first, service first, and win-win cooperation", as well as the diversified development of our products and services, to better provide customers and friends with comprehensive high-quality services; We approach large, medium, and small enterprises and end customers around the world with a responsible attitude, adhering to our commitments and establishing a good reputation in the industry; In the future, we will continue to provide high-quality products, professional services, and a responsible attitude to more friends, strengthen communication and communication, promote technology improvement, and contribute to your development to achieve win-win cooperation.