- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

12

-

Type:

-

wood sawdust pallet block press machine

-

Wood block size:

-

75*75mm-120*140mm

-

Key words:

-

wood powder blocks making machines

-

Capacity:

-

2-9m3/24h

-

Density:

-

550-600kg/m3

-

Efficiency:

-

m3/24h

-

Application:

-

European standard wood pallet

-

Raw material:

-

wood sawdust, wood shaving and glue

-

Raw materials Water content:

-

<10%

-

Dimension:

-

4800*780*1320mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Machine Type:

-

wood sawdust pallet block press machine

-

Weight (KG):

-

500 KG

-

Power (kW):

-

12

-

Type:

-

wood sawdust pallet block press machine

-

Wood block size:

-

75*75mm-120*140mm

-

Key words:

-

wood powder blocks making machines

-

Capacity:

-

2-9m3/24h

-

Density:

-

550-600kg/m3

-

Efficiency:

-

m3/24h

-

Application:

-

European standard wood pallet

-

Raw material:

-

wood sawdust, wood shaving and glue

-

Raw materials Water content:

-

<10%

-

Dimension:

-

4800*780*1320mm

Products Description

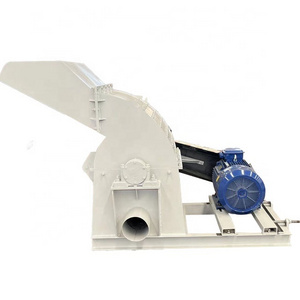

The wood block press machine generally uses waste such as shavings, sawdust, rotten wood boards, and branches as raw materials. The raw materials are first screened and classified to prevent the machine from being damaged due to hard debris such as metal in the raw materials.Then it is pulverized by crusher (when the raw material is less than 5*5mm, it does not need to be pulverized), it is dried in a dryer, glued by a glue mixer, and then hydraulically formed by a hot press abrasive tool, and extruded into a wooden pier product.

|

Model

|

Power

|

Efficiency(m3/24h)

|

Glue Needed (kg/m3)

|

Density of the supports(kg/m3)

|

|

HS75*75

|

12kw

|

2-3

|

80-100

|

550-600

|

|

HS80*80

|

12kw

|

2-3

|

80-100

|

550-600

|

|

HS80*90

|

15kw

|

2-3

|

80-100

|

550-600

|

|

HS90*90

|

15kw

|

3-4

|

80-100

|

550-600

|

|

HS100*100

|

16kw

|

4-5

|

80-100

|

550-600

|

|

HS100*120

|

18kw

|

4-5

|

80-100

|

550-600

|

|

HS120*120

|

18kw

|

4-5

|

80-100

|

550-600

|

|

HS120*140

|

19kw

|

5-6

|

80-100

|

550-600

|

|

HS140*145

|

19kw

|

5-6

|

80-100

|

550-600

|

Detailed images

1. Compared with multi-layer boards, the specifications are unified and the appearance is consistent, which improves the appearance and grade of the product;

2.Smooth on all sides, no need to polish; good water resistance (no cracking after soaking in water for 48 hours, no cracking under wind and sun), strong nailing force. Different from the sawdust pier cut by the whole board, the surface is rough and easy to drop slag;

3.Uniform heating around and in the middle, the glue is cured thoroughly, and the product has high strength;

4.The surface is smooth, water is not easy to penetrate, and the fiber binding force of the shavings itself makes the product have excellent water resistance.

5.The raw material itself has more crude fibers, the interior is criss-crossed, and the structure is strong, so it is not easy to crack after eating nails.

Stainless steel chilli stem cutting machine

Packing & Delivery

Hot Searches