- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Liaoning

-

Model Number:

-

ECS 65P

-

Power:

-

6.0

-

Material:

-

bulk in container

-

Warranty of core components:

-

8year

-

Weight (KG):

-

3000 kg

-

eccentric pole eddy current separator:

-

ECS65P

-

belt width of ECS:

-

650mm

-

effective belt width:

-

400mm

-

drum magnetic intensity:

-

3000gs

-

Suitable power system:

-

220v/3/ph/60hz Japan Taiwan

-

productivity for glass recycling:

-

3-4tons per hour

-

productivity metal remove PET plastic:

-

300-500kg per hour

-

Productivity PP ABS PA PET POM:

-

500-700kg/h

-

Productivity scraps aluminum recycling:

-

1-1.2tons per hour

-

productivity Incineration bottom ash IBA:

-

4-6tons per hour

Quick Details

-

Production Capacity:

-

Other

-

Applicable Industries:

-

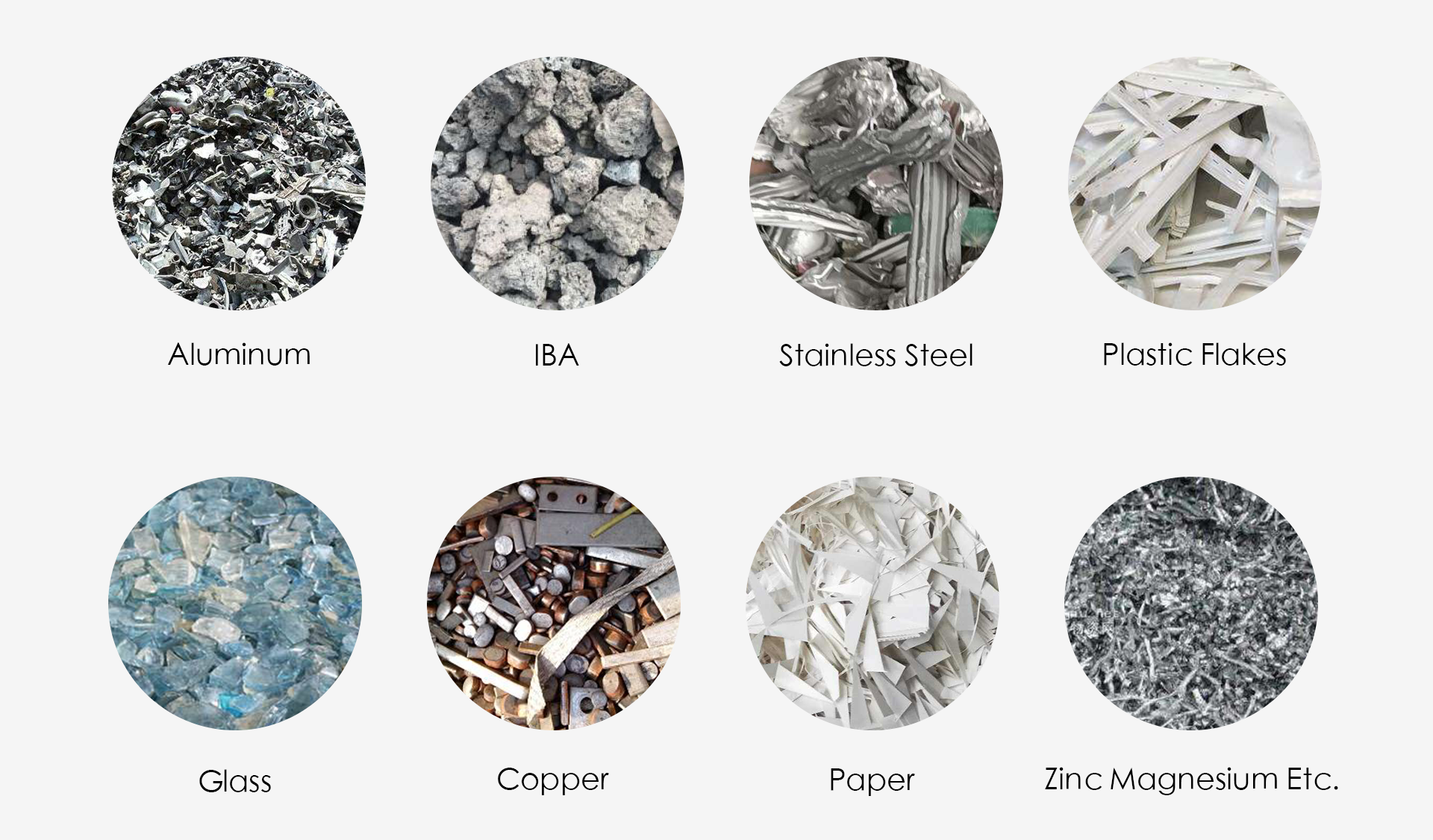

E Waste Recycling Plant Machinery, Computers and Electronics waste recycling, shredded old electronics scraps recycling, Waste Electrical and Electronic Equipment, e-waste, treatment of auto shredder residue, Shredding of automotive shredder residue, Car Fluff, mixture of copper and aluminum materials process, recyclable scrap metals, Shredder Light Fraction (SLF), Electric and Electronic Equipment (WEEEs), solution to separate ferrous and non ferrous metal, Auto ShredderResidue ASR, Scrap Metal Processing, ALUMINUM RECYCLING SOLUTIONS, metal separation solutions in glass recycling, metallic removal separation in plastic recycling

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Liaoning

-

Model Number:

-

ECS 65P

-

Power:

-

6.0

-

Material:

-

bulk in container

-

Warranty of core components:

-

8year

-

Weight (KG):

-

3000 kg

-

eccentric pole eddy current separator:

-

ECS65P

-

belt width of ECS:

-

650mm

-

effective belt width:

-

400mm

-

drum magnetic intensity:

-

3000gs

-

Suitable power system:

-

220v/3/ph/60hz Japan Taiwan

-

productivity for glass recycling:

-

3-4tons per hour

-

productivity metal remove PET plastic:

-

300-500kg per hour

-

Productivity PP ABS PA PET POM:

-

500-700kg/h

-

Productivity scraps aluminum recycling:

-

1-1.2tons per hour

-

productivity Incineration bottom ash IBA:

-

4-6tons per hour

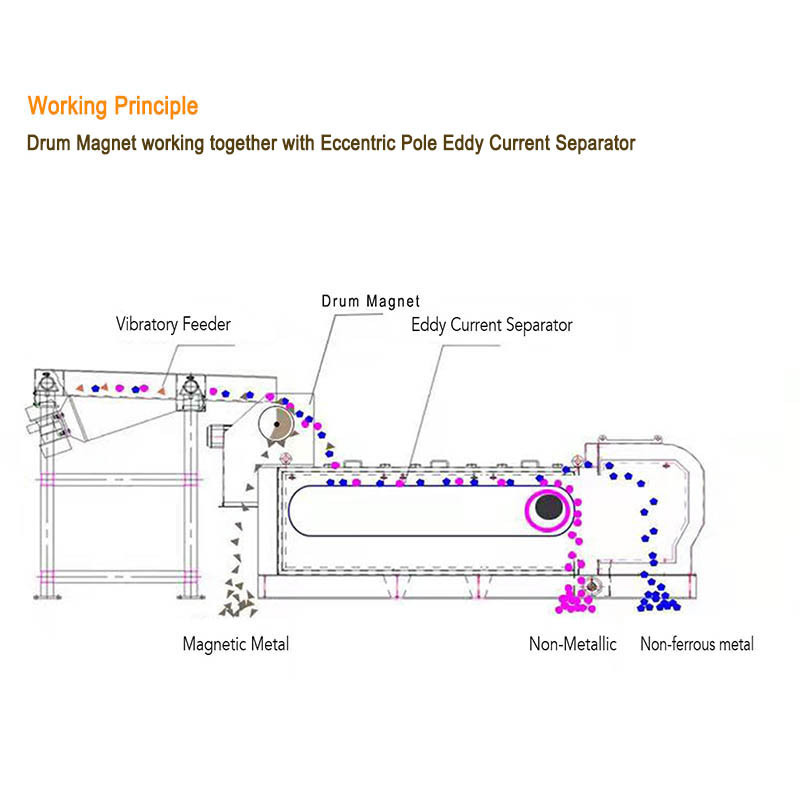

Typical stages of metal separation in Auto Shredding Residue (ASR)and Appliances recycling process after A

fter car bodies are shredded in automobile demolition industry,

old Electric and Electronic Equipment WEEEs E-waste ; Construction and Demolition Waste (C&D); Municiple Solid Waste ,Household Waste , Waste to Energy ,Refuse Derived Fuel (RDF) etc Commercial and Industrial Waste (C&I)

1. primary removal of iron and steel using

Drum electromagnet , suspended

overband iron remover or pulley magnetic drum

Drum electromagnet , Belt, and permanent Pulley Magnets

.

2. Eccentric Pole Eddy currents separator and UHF ECS for optimum recovery copper brass aluminum magnesium non–ferrous metallic (NF),

3. Induction Electromagnetic sensor sorter to removal remaining valuable stainless steel wire etc metallic material from the ECS drops

2. Eccentric Pole Eddy currents separator and UHF ECS for optimum recovery copper brass aluminum magnesium non–ferrous metallic (NF),

3. Induction Electromagnetic sensor sorter to removal remaining valuable stainless steel wire etc metallic material from the ECS drops

Magnetic separation Devices

a wide variety of powerful Rare Earth Magnetic Separators to capture and hold ferrous and weakly magnetic stainless steel from the mixture

Eccentric Eddy current separator

1.High Intensity Eccentric & Concentric Eddy Current Separator for scraps nonferrous

2.Ultra High Frequency UHF ECS for micro-fine nonferrous particles recovery

Induction Sensor Sorter

normally for the waste that separated by the non-ferrous separator to recover rest of stainless steel and insulation wire et

c

Air separation machine

for pre-treatment of dusty material --

a light fraction capable of flight, known as the shredder light fraction (SLF)

Trommel screen

or rotary screen, is a kind of mechanical screening machine widely used in the separation operation. to controls the

material separation by the particle size

material separation by the particle size

Belt conveyor

the conveyor system could be customized strictly according customer`s working side .

Customer Photos

Working site in Thailand for Zorba processing

best-in-class ferrous and non-ferrous recovery rates for shredding operations.

Zorba purification

AUTOMOBILE shredder-residue ASR SHF SLF Fluff processing system for metal recovery

Other Working Site ----Metal Solution in Recycling

OTHER INDUSTRIAL MAGNET SEPARATION TECHNOLOGY SERVED IN

1.AUTOMOBILE SHREDDING & SCRAP METAL PROCESSING,such as Car bodies ,Mixed scrap, Aluminum Can Recycling

2.ADVANCED METAL Automotive white goods RECOVERY & SORTING ,such as Engine blocks ,Aluminium rims and

profiles ,etc ALUMINUM/alumina SHREDDING & SORTING

3.WASTE TO ENERGY Power Plants for maximizing metal extraction from the incineration bottom ash

4.MUNICIPAL SOLID WASTE RECYCLING

5.E-SCRAP RECYCLING

6.ferromagnetic and Nno-ferrous metals recycling in steel mills and foundries Applications

7.Food, Chemical, Pharmaceuticals

8.Lumber/ Waste wood processing

9. Mining/Minerals

10.Quarry/Aggregate

Hot Searches