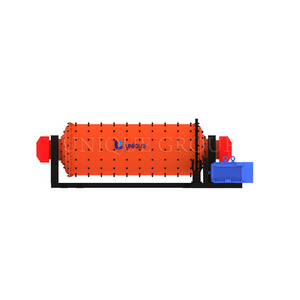

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

900*3000

-

Weight:

-

5600 KG

-

Application:

-

Stone Powder Grinding

-

Product name:

-

Ball Mill Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Name:

-

High Pressure Grinding Mill

-

Keywords:

-

Grinding Miller Ball Mill

-

The Machines classification:

-

Granding Mill Machine

-

Color:

-

Customer Requirement

-

Grinding media:

-

Steel Ball

-

Usage:

-

Grinding Mining Stone

-

Model:

-

Grinding Ball Mill Machine

Quick Details

-

Capacity(t/h):

-

1.1-3.5

-

Place of Origin:

-

Henan China

-

Brand Name:

-

Santai Machinery

-

Dimension(L*W*H):

-

900*3000

-

Weight:

-

5600 KG

-

Application:

-

Stone Powder Grinding

-

Product name:

-

Ball Mill Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Name:

-

High Pressure Grinding Mill

-

Keywords:

-

Grinding Miller Ball Mill

-

The Machines classification:

-

Granding Mill Machine

-

Color:

-

Customer Requirement

-

Grinding media:

-

Steel Ball

-

Usage:

-

Grinding Mining Stone

-

Model:

-

Grinding Ball Mill Machine

Products Description

High capacity small gold ball mill for grinding gold ore

The ball mill cylinder is embedded with wear-resistant lining plates, which have good wear resistance. This machine runs smoothly,has reliable performance, and high efficiency. In addition, it adopts full hydraulic operation, which is convenient to use and easy to achieve automation, greatly improving its reliability and lifespan

.

Professional Energy Saving Continuous Grinding Mill Cement Production Line Small Gold Ore Ball Mill

|

Model

|

Cylinder size

(DxL)(mm)

|

Rotary speed

(r/min)

|

Power

(kw)

|

Discharge size

(mm)

|

Capacity

(t/h)

|

Weight

(t)

|

|

MB0918

|

900*1800

|

38

|

22

|

5-0.2

|

6-1.6

|

6.2

|

|

MB0924

|

900*2400

|

38

|

30

|

5-0.2

|

10-2.9

|

6.6

|

|

MB1224

|

1200*2400

|

32

|

55

|

5-0.2

|

15-5

|

13.5

|

|

MB1530

|

1500*3000

|

27

|

75

|

5-0.2

|

20-5

|

16.7

|

|

MB1830

|

1800*3000

|

22.8

|

132

|

5-0.2

|

40-10

|

29.8

|

The ball mill is a horizontal cylindrical turning gear, a skeleton type ball mill driven by an external gear and two hoppers. The material enters the first hopper through the hollow shaft spiral of the feeding equipment. The hopper has a trapezoidal or corrugated sheath, containing steel balls that fall under the centrifugal force of the cylinder and grind the material. After

rough grinding in the first hopper, the material enters the second hopper through a single-layer partition. There is a flat scale plate with steel balls inside the second hopper for grinding the material. The powder is discharged from the grid plate and the grinding is completed

rough grinding in the first hopper, the material enters the second hopper through a single-layer partition. There is a flat scale plate with steel balls inside the second hopper for grinding the material. The powder is discharged from the grid plate and the grinding is completed

Ball mills are used for crushing iron ore, copper ore, lead zinc ore, gold ore, steel slag, water slag, coal slag, limestone,fluorite, barite, potassium feldspar, coal gangue, fly ash, white ash, desulfurization gypsum, cement clinker, cement, refractorymaterials, etc.

Product packaging

All products will be processed to be rustproof and moisture proof before delivery

Using standard export packaging, bare packaging, containers, or according to customer requirements

Using standard export packaging, bare packaging, containers, or according to customer requirements

Hot Searches