- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C

-

EINECS No.:

-

231-153-3

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kelin

-

Model Number:

-

Kelin-IOD

-

Product name:

-

Lithium Zeolite 13X

-

Application:

-

Oxygen Generation Industry

-

Function:

-

Oxygen Generation

-

Certification:

-

ISO9001:2008

-

Package:

-

25kg/bag

-

Appearance::

-

Ball or Honeycomb Shape

-

Sample:

-

Free

-

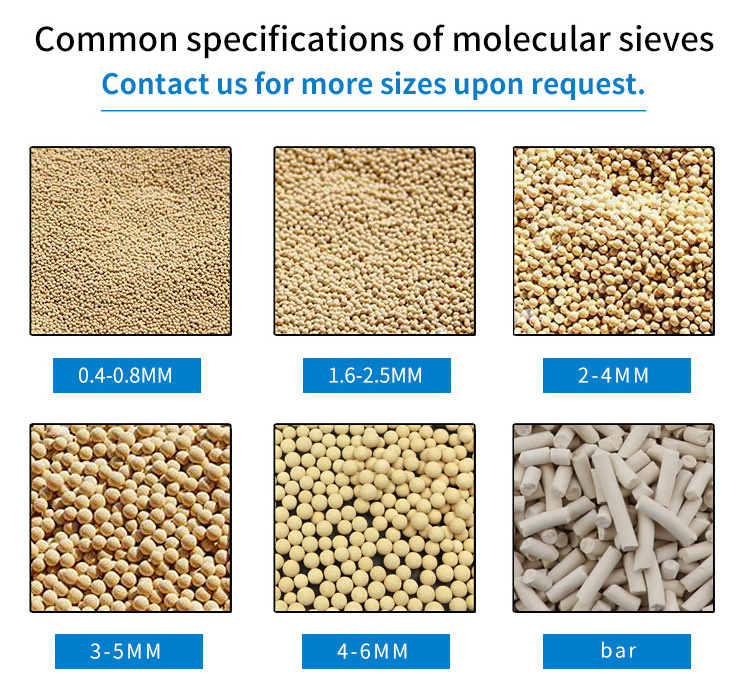

Size:

-

1.0~1.8mm

-

O2 purity::

-

≥95%

-

Bulk density:

-

0.61-0.64 g/ml

Quick Details

-

CAS No.:

-

1332-37-2

-

Purity:

-

100%

-

Other Names:

-

Zeolite

-

MF:

-

C

-

EINECS No.:

-

231-153-3

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kelin

-

Model Number:

-

Kelin-IOD

-

Product name:

-

Lithium Zeolite 13X

-

Application:

-

Oxygen Generation Industry

-

Function:

-

Oxygen Generation

-

Certification:

-

ISO9001:2008

-

Package:

-

25kg/bag

-

Appearance::

-

Ball or Honeycomb Shape

-

Sample:

-

Free

-

Size:

-

1.0~1.8mm

-

O2 purity::

-

≥95%

-

Bulk density:

-

0.61-0.64 g/ml

Product Description

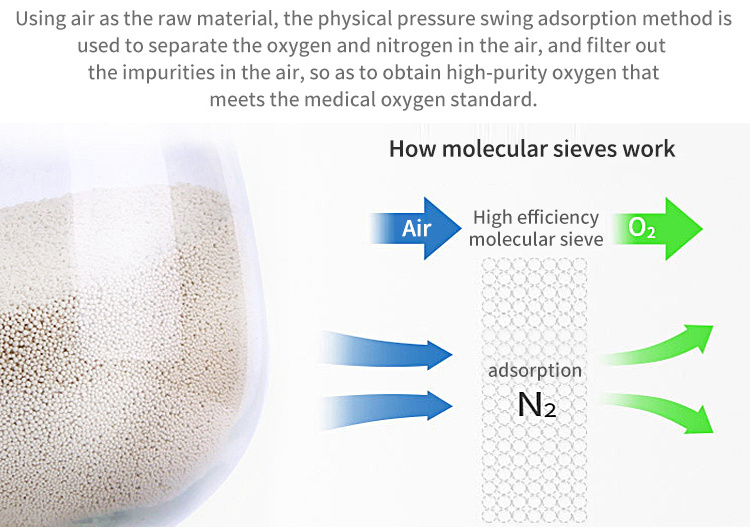

Molecular Sieve is a highly porous substance that is widely used in the adsorption and separation processes of gases and liquids. The characteristic of these porous materials is that their pore sizes are very consistent, allowing them to selectively adsorb molecules of specific sizes, just like a sieve, hence the name "molecular sieve".

The basic framework of molecular sieves is usually composed of silicates (silicon, oxygen) or aluminosilicates (aluminum, silicon, oxygen). Their corresponding pore sizes can range from 2 angstroms to 10 angstroms, which can cope with various adsorption needs.

Specifications

|

Molecular Sieve

|

|

|

|

|

|

|

|

|

||||||||

|

Model

|

3A Molecular Sieve

|

|

4A Molecular Sieve

|

|

5A Molecular Sieve

|

|

13X Molecular Sieve

|

|

||||||||

|

Nominal pore diameter

|

3 angstroms

|

|

4 angstroms

|

|

5 angstroms

|

|

10 angstroms

|

|

||||||||

|

Diameter

|

1.7-2.5 (mm)

|

3.0-5.0 (mm)

|

1.7-2.5 (mm)

|

3.0-5.0 (mm)

|

1.7-2.5 (mm)

|

3.0-5.0 (mm)

|

1.7-2.5 (mm)

|

3.0-5.0 (mm)

|

||||||||

|

|

8*12 (mesh)

|

4*8 (mesh)

|

8*12 (mesh)

|

4*8 (mesh)

|

8*12 (mesh)

|

4*8 (mesh)

|

8*12 (mesh)

|

4*8 (mesh)

|

||||||||

|

Bulk density (g/ml)

|

≥0.70

|

≥0.70

|

≥0.70

|

≥0.70

|

≥0.66

|

≥0.66

|

≥0.66

|

≥0.66

|

||||||||

|

Crushing strength (N/PC)

|

≥55.0

|

≥85.0

|

≥35.0

|

≥80.0

|

≥30.0

|

≥70.0

|

≥25.0

|

≥80.0

|

||||||||

|

Static H2O adsorption (%)

|

≥21.0

|

≥21.0

|

≥21.5

|

≥21.5

|

≥21.5

|

≥21.5

|

≥25

|

≥25

|

||||||||

|

Wear ratio (%)

|

≤0.25

|

≤0.25

|

≤0.40

|

≤0.40

|

≤0.20

|

≤0.20

|

≤0.20

|

≤0.20

|

||||||||

Applications

3A zeolite molecular sieve

3A molecular sieve has many advantages. It has consistently high absorption rates, strong crush strength, and high resistance to contamination, resulting in increased cycle times and therefore longer product life. For these reasons, it has become one of the most reliable desiccants and is commonly used in the following applications:

1. Freeze drying

2. Natural gas drying

3. Moisture removal from paint or PU plastic

4. Dry cracked gas

5. Static drying of insulating air or gas-filled glass installations

6. Dehydration of highly polar compounds such as methanol and ethanol

7. Dehydration of unsaturated hydrocarbons (such as ethylene, propylene, butadiene)

Molecular sieve 3A can also be regenerated and reused by removing absorbed moisture and other materials and then heating it to 250 degrees Fahrenheit. Then store the sieve in an airtight container until ready to use again to avoid accidental moisture absorption.

4A zeolite molecular sieve

The 4A molecular sieve has an Angstrom size of 4, so any molecules larger than 4A cannot be absorbed. 4 Angstroms is the form of sodium known as the A-type crystal structure, with the following order of absorbance: argon, krypton, xenon, ammonia, carbon monoxide, C2H4, C2H2, CH3OH, C2H5OH, CH3CN2, CS2, CH3CL, CH3Br, and carbon dioxide.

Also used in the following applications:

1. Freeze drying

2. Natural gas drying

3. Moisture removal from paint or PU plastic

4. Dry cracked gas

5. Static drying of insulating air or gas-filled glass installations

6. Dehydration of highly polar compounds such as methanol and ethanol

7. Dehydration of unsaturated hydrocarbons (such as ethylene, propylene, butadiene)

Like the 3A sieve, the Type 4A sieve can be reused and regenerated. First, you need to remove the absorbed moisture and other materials, then heat it to 250 to 450 degrees Fahrenheit. Then store the sieve in an airtight container until ready to use again to avoid accidental moisture absorption.

5A zeolite molecular sieve

The 5A molecular sieve has a pore size of 5 Angstroms, which means it cannot absorb molecules smaller than 5A. This type is an alkali metal aluminosilicate with a type A crystal structure. This means it will separate normal and isoparaffins, co-absorption of moisture and carbon dioxide, and pressure swing absorption (PSA) of various gases. The adsorption rate of 5A sieve is: C3-C14, C2H5CL, C2H5Br, CH3L, C2H5NH2, CH2CL2CH2Br2, CHF2CL, CHF3, CF4, (CH3)NH2, B2H6CF2CL2, CHFCL2, CF3CL.

Sieve Type 5A is a reliable desiccant suitable for the following applications:

1. Normal paraffin separation process

2. Oxygen/Hydrogen PSA (Pressure Swing Adsorption) Process

3. SF6 refrigerant for power refining (moisture and hydrocarbon removal)

13X

zeolite molecular sieve

Molecular Sieve 13X is the sodium form of the type X crystal and has a much larger pore opening than the type A crystals. It will adsorb molecules with a kinetic diameter of less than 9 Angstrom (0.9 nm) and exclude those larger.

It also has the highest theoretical capacity of the common adsorbents and very good mass transfer rates. It can remove impurities too large to fit into a type A crystal and is commonly used to separate nitrogen from oxygen.

It also has the highest theoretical capacity of the common adsorbents and very good mass transfer rates. It can remove impurities too large to fit into a type A crystal and is commonly used to separate nitrogen from oxygen.

Application

Removal of CO2 and moisture from air (air pre-purification) and other gases.

Separation of enriched oxygen from air.

Removal of mercaptans and hydrogen sulphide from natural gas.

Removal of mercaptans and hydrpogen sulphide from hydrocarbon liquid streams (LPG, butane, propane etc.)

Catalyst protection, removal of oxygenates from hydrocarbons (olefin streams).

Production of bulk oxygen in PSA units .

Production of medical oxygen in small scale oxygen concentrators

Regeneration:

Molecular sieve Type 13X can be regenerated by either heating in the case of thermal swing processes; or by lowering the pressure

in the case of pressure swing processes.

To remove moisture from a 13X molecular sieve, a temperature of 250-300°C is required. A properly regenerated molecular sieve can

give moisture dew points below -100°C, or mercaptan or CO2 levels below 2 ppm.

The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process

Attention

To avoid damp and pre-adsorption of organic before running, or must to be reactivated.

Removal of CO2 and moisture from air (air pre-purification) and other gases.

Separation of enriched oxygen from air.

Removal of mercaptans and hydrogen sulphide from natural gas.

Removal of mercaptans and hydrpogen sulphide from hydrocarbon liquid streams (LPG, butane, propane etc.)

Catalyst protection, removal of oxygenates from hydrocarbons (olefin streams).

Production of bulk oxygen in PSA units .

Production of medical oxygen in small scale oxygen concentrators

Regeneration:

Molecular sieve Type 13X can be regenerated by either heating in the case of thermal swing processes; or by lowering the pressure

in the case of pressure swing processes.

To remove moisture from a 13X molecular sieve, a temperature of 250-300°C is required. A properly regenerated molecular sieve can

give moisture dew points below -100°C, or mercaptan or CO2 levels below 2 ppm.

The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process

Attention

To avoid damp and pre-adsorption of organic before running, or must to be reactivated.

13X APG

zeolite molecular sieve

Type 13X APG molecular sieve is specially designed to co-absorb CO2 and H2O for air cryo-separation industry. It has largeer capacity and faster adsorption speed for removal of CO2 and H2O to prevent the bed gelation, it is suitable for any air cryo-separation plants of any size and any types in the world.

Attention

To avoid damp and pre-adsorption of organic before running, or must to be reactivated.

To avoid damp and pre-adsorption of organic before running, or must to be reactivated.

XH-5

zeolite molecular sieve

The pore size of XH-5 molecular sieve crystal is about 4Å (0.4 nm), and it is mainly used for drying and purifying R12 and R22 refrigerants, and drying automotive air systems, including the removal of moisture in automotive air conditioning systems and air brake systems.

XH-7

zeolite molecular sieve

The pore size of XH-7 molecular sieve crystal is about 3Å (0.3 nm), which is suitable for dehydration and drying of new refrigerant R-139a for refrigerators, freezers, and air conditioners, and special refrigerants such as butane.

XH-9

zeolite molecular sieve

The pore size of XH-9 molecular sieve crystal is about 3Å (0.3 nm), which is suitable for the drying of various refrigerants (except mixed refrigerants containing difluoromethane), and the dehydration and drying of new refrigerants in refrigerators, freezers and air conditioners. It is a general-purpose desiccant.

Packing & Delivery

1. 25kg/bag

2.

750Kg

/jumbo bag

3.

30Kg (cardboard drum) sealed steel drum

4.

150Kg (55 gallon) sealed steel drum

5. Customize Packaging as per your request.

Hot Searches