- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2300 KG, 2000KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Category:

-

Organic compounds dryer ,Inorganic compound dryer

-

Barrel diameter:

-

200-1600 mm

-

Occupied area:

-

3500-4500

-

Air flow amount:

-

300-36000

-

Material:

-

Carbon steel,stainless steel

-

Heating source:

-

Steam+electricity+gas furnace

-

Certification:

-

CE;ISO9001:2000

Quick Details

-

Machinery Capacity:

-

as customer's request

-

Brand Name:

-

YIBU

-

Year:

-

2023

-

Weight:

-

2300 KG, 2000KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Category:

-

Organic compounds dryer ,Inorganic compound dryer

-

Barrel diameter:

-

200-1600 mm

-

Occupied area:

-

3500-4500

-

Air flow amount:

-

300-36000

-

Material:

-

Carbon steel,stainless steel

-

Heating source:

-

Steam+electricity+gas furnace

-

Certification:

-

CE;ISO9001:2000

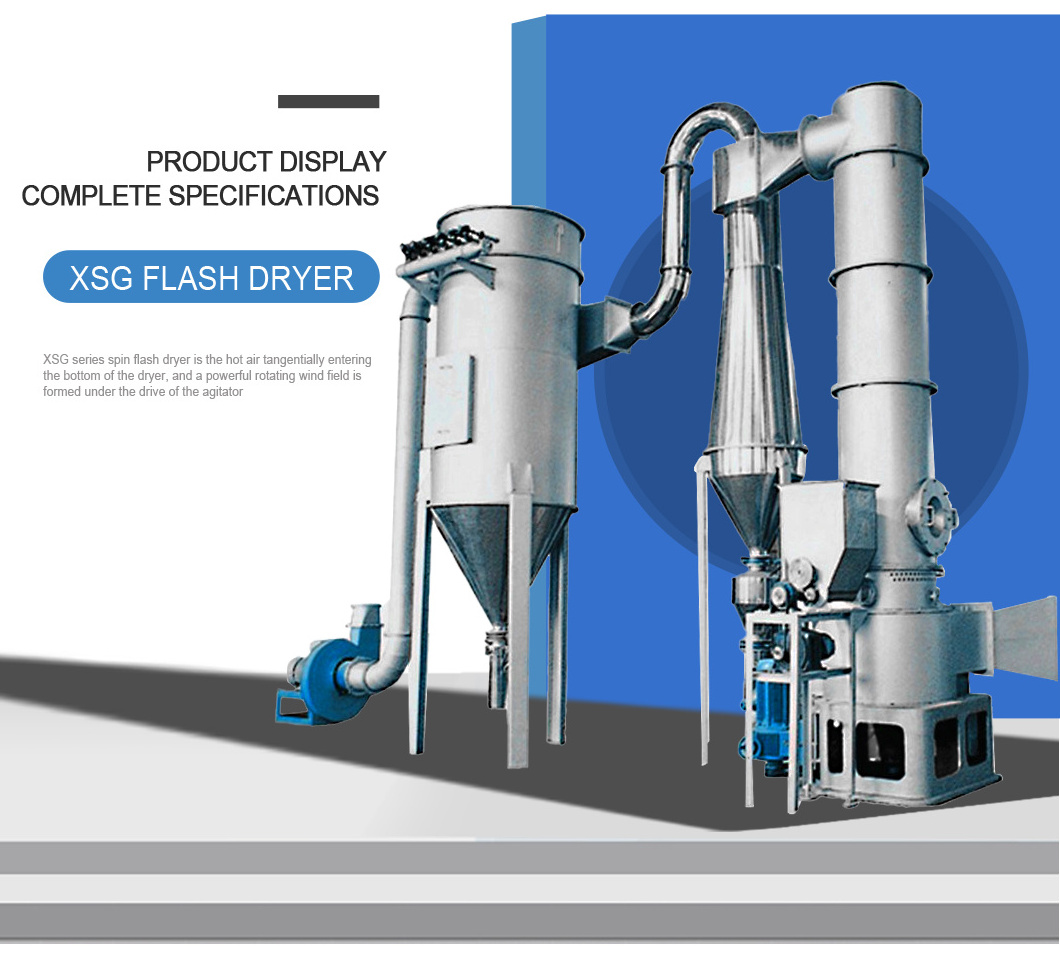

Copper sulfate oxide spin flash dryer for chemical industry

Description

Absorbed the foreign advanced equipment and technology,our factory and Shenyang Chemical Research Institute of the Chemical Ministry of the State have developed this machine.This is a new kind of drying equipment used for drying the materials,such as paste state, cake state, thixotropy,thermal senstive powder and particles.Our factory is equipped with the testing sample machine,which can be used for carrying out the drying tests of various feeds for our users and for to provide the parameters to select the applicable machine

(Main machine picture) (Certificate)

Specifications

(1).Metallic hydroxide Rotating Flash Dryer,XSG

(2).Widely used

(3).Large handling capacity ,Low energy consumption

(4).GMP ;

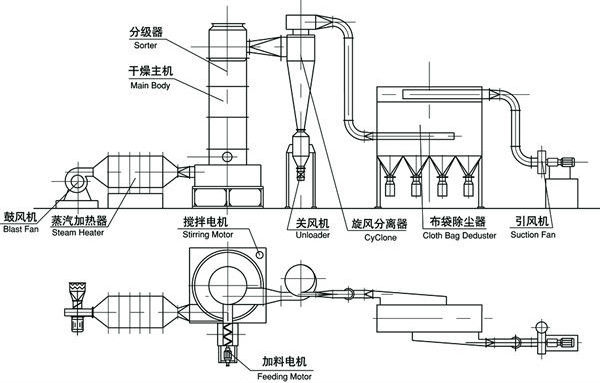

Principle

Hot air enters into stirring and crushing and drying chamber from the bottom of drier with suitable spouting speed. It exerts strong shearing, blowing, floating and rotating effect. It strengthens the process of heat and mass transfer. At the bottom of drier, the large and damp granule is crushed under the action of stirrer and the granule that is small in particle and contain less moisture will lift accompanied with revolving air steam. During the period of lift, it is dried further. Because gas and solid two phase flow in rotating and the inertia of solid phase is more than that of gas and the relative velocity between solid and gas phase is large, so it strengthens the process of heat and mass transfer. Therefore the machine has large drying capacity.

Feature

1. There are many kinds feeding equipment for choosing and feeding is continue and static.

2. There is a cooling device at the bottom of drier, where is high temperature area heat sensitivity raw material can not contact with heat surface directly, therefore it solves the metamorphose problem of heat sensitivity raw material.

3. There are pressured seal and bearing cooling device, so can make the life of machine longer.

4. There is special equipment for sharing wind, and raising the amount of hot air.

5. There are rotational flow pieces inside the drying chamber. It is used to control the moisture and granule of raw material to needed level.

6. The machine could add specific gravity of materials compare with other drying method.

7. Because gas speed at circle inside the drying chamber is high and the staying time of raw material is short, so it could prevent material stick to me wall and metamorphose problem, high efficiency and quick speed can be realized. 8. It is possible for small equipment to carry out large-scale production.

8. This machine combines the whirl technology with the fluidity .ejection and smashing step technologies.

9. The equipment is compact and small in size ,high in production efficiency and continuous in the production .It has realized that "a small equipment can perform the large production ".

10.The drying capacity for this machine is big but its energy consumption is low. Its heat efficiency is high.

11.The materiral stay time is very short .The quality of the final products is very good ,The machine can be used for drying the heat sensitive materials .

12.For the negative pressure or the micro-negative pressure operation ,the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution

Suitable Material

Inorganic compounds: borax, calcium carbonate, hydroxide, copper sulfate oxide, barium carbonate, antimony trioxide, all kinds of metallic hydroxide, all kinds of heavy metallic salt, synthetic cryolite and so on.

Organic compounds : fenatrol (insecticide of agrochemicals), cadmium laurate, benzoic acid, germicide, sodium oxalate, cellulose acetate and so on.

Ceramics : kaoline, silicone trioxide, clay and so on.

Dyestuff : anthraquinone, black ferric oxide, indigo blue pigment, butyric acid, titanium hydroxide, zinc sulfide, all kinds of intermediate of azo dye stuff.

Foodstuff : soya protein, agglomerative starch, less, tritcin, wheat starch and so on.

(Detail picture) (CE CERTIFICATE)

Processing machines for our Equipments

As to achieve high quality of machine , we adopted the advantaged processing equipments for manufacturing our machines.

Packaging & Shipping

Packing Size: depending on the machine

Container Load: 20OT ,20GP , 40OT , 40GP and 40FR

Outer Packing: plastic film or wooden case

Our Services

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents as customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.