- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Slightly Oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Outer Diameter:

-

5 - 250 mm

-

Length:

-

as per standard

-

Grade:

-

E235/255/355, E235/255/355

-

Product name:

-

Cold Rolled Seamless Pipes

-

Material:

-

Seamless Steel

-

Usage:

-

Construction

-

End protector:

-

Plastic Pipe Cap

-

Quality:

-

High-quality

-

Secondary Or Not:

-

Non-secondary

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Cold Rolled

-

Tolerance:

-

±10%, +/-0.05mm or as per standard

-

Oiled or Non-oiled:

-

Slightly Oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Outer Diameter:

-

5 - 250 mm

-

Length:

-

as per standard

-

Grade:

-

E235/255/355, E235/255/355

-

Product name:

-

Cold Rolled Seamless Pipes

-

Material:

-

Seamless Steel

-

Usage:

-

Construction

-

End protector:

-

Plastic Pipe Cap

-

Quality:

-

High-quality

-

Secondary Or Not:

-

Non-secondary

Product Description

Standard

|

Standard

|

Material Chemical Composition (%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Steel Grade

|

Material Number

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

||||||||

|

DIN 2391

|

ST35

|

1.0308

|

≦ 0.17

|

≦ 0.35

|

≧0.04

|

≦0.025

|

≦0.025

|

-

|

-

|

||||||||

|

|

ST45

|

1.0408

|

≦ 0.21

|

≦ 0.35

|

≧0.04

|

≦0.025

|

≦0.025

|

-

|

-

|

||||||||

|

|

ST52

|

1.058

|

≦ 0.22

|

≦ 0.55

|

≦1.60

|

≦0.025

|

≦0.025

|

-

|

-

|

||||||||

|

Standard

|

Material Chemical Composition (%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Steel Grade

|

Material Number

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

||||||||

|

DIN1629

|

ST37

|

1.0254

|

≦ 0.17

|

≦ 0.55

|

≦1.60

|

≦0.04

|

≦0.04

|

-

|

-

|

||||||||

|

|

ST44

|

1.0258

|

≦ 0.21

|

≦ 0.55

|

≦1.60

|

≦0.04

|

≦0.04

|

-

|

-

|

||||||||

|

|

ST52

|

1.0421

|

≦ 0.22

|

≦ 0.55

|

≦1.60

|

≦0.04

|

≦0.035

|

-

|

-

|

||||||||

|

DIN1630

|

ST37.4

|

1.0255

|

≦ 0.17

|

≦ 0.35

|

≧0.035

|

≦0.04

|

≦0.04

|

-

|

-

|

||||||||

|

|

ST44.4

|

1.0257

|

≦ 0.21

|

≦ 0.35

|

≧0.04

|

≦0.04

|

≦0.04

|

-

|

-

|

||||||||

|

|

ST52.4

|

1.0281

|

≦ 0.22

|

≦ 0.55

|

≦1.60

|

≦0.04

|

≦0.035

|

-

|

-

|

||||||||

|

Standard

|

Material Chemical Composition (%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Steel Grade

|

Material Number

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

||||||||

|

EN10305-1

EN10305-4 |

E235

|

1.0308

|

≦ 0.17

|

≦ 0.35

|

≧0.04

|

≦0.025

|

≦0.025

|

-

|

-

|

||||||||

|

|

E255

|

1.0408

|

≦ 0.21

|

≦ 0.35

|

≧0.04

|

≦0.025

|

≦0.025

|

-

|

-

|

||||||||

|

|

E355

|

1.058

|

≦ 0.22

|

≦ 0.55

|

≦1.60

|

≦0.025

|

≦0.025

|

-

|

-

|

||||||||

|

Standard

|

Material Chemical Composition (%)

|

|

|

|

|

|

|

|

|

|||||||

|

|

Steel Grade

|

Material Number

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

|||||||

|

ASTM

A519

|

1010

|

-

|

0.08-0.13

|

-

|

0.3-0.6

|

≤0.04

|

≤0.05

|

-

|

-

|

|||||||

|

|

1020

|

-

|

0.18-0.23

|

-

|

0.3-0.6

|

≤0.04

|

≤0.05

|

-

|

-

|

|||||||

|

|

1045

|

-

|

0.43-0.50

|

-

|

0.6-0.9

|

≤0.04

|

≤0.05

|

-

|

-

|

|||||||

|

|

4130

|

-

|

0.28-0.33

|

0.15-0.35

|

0.40-0.60

|

≤0.04

|

≤0.05

|

0.8-1.1

|

0.15-0.25

|

|||||||

|

|

4140

|

-

|

0.38-0.43

|

0.15-0.35

|

0.75-1.0

|

≤0.04

|

≤0.05

|

0.8-1.1

|

0.15-0.25

|

|||||||

|

Standard

|

Material Chemical Composition (%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Steel Grade

|

Material Number

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

||||||||

|

JIS G3445

|

SKTM 12C

|

-

|

≦ 0.12

|

≦ 0.35

|

≦ 0.60

|

≦0.04

|

≦0.04

|

-

|

-

|

||||||||

|

|

STKM 13C

|

-

|

≦ 0.25

|

≦ 0.35

|

0.3-0.9

|

≦0.04

|

≦0.04

|

-

|

-

|

||||||||

|

Standard

|

Material Chemical Composition (%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Steel Grade

|

Material Number

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

||||||||

|

GB/T 8162 GB/T 8163 GB/T 3639

|

10

|

-

|

0.07-0.14

|

0.17-0.35

|

0.35-0.65

|

≦0.035

|

≦0.04

|

-

|

-

|

||||||||

|

|

20

|

-

|

0.17-0.23

|

0.17-0.37

|

0.35-0.65

|

≤0.035

|

≤0.035

|

-

|

-

|

||||||||

|

|

45

|

-

|

0.42-0.50

|

0.17-0.37

|

0.50-0.80

|

≤0.035

|

≤0.035

|

-

|

-

|

||||||||

|

|

Q345B

|

-

|

≤0.20

|

≤0.50

|

≦1.70

|

≤0.035

|

≤0.035

|

-

|

-

|

||||||||

Delivery Condition: BKW, BKS, +LC, +SR

ID tolerance can minimized to +/-0.02mm

OD: 5- 250mm

ID: 3- 200mm

ID tolerance can minimized to +/-0.02mm

OD: 5- 250mm

ID: 3- 200mm

|

Equivalent Material referance:

|

|

|

|

|

|

|

||||||

|

GB

|

TOCT

|

ASTM

|

BS

|

JIS

|

NF

|

DIN

|

||||||

|

10F

|

|

1010

|

040A10

|

|

XC10

|

|

||||||

|

10

|

10

|

10,101,012

|

045M10

|

S10C

|

XC10

|

C10,CK10

|

||||||

|

20

|

20

|

1020

|

050A20

|

S20C

|

XC18

|

C22,CK22

|

||||||

|

45

|

45

|

1045

|

080M46

|

S45C

|

XC45

|

C45,CK45

|

||||||

|

30CrMo

|

30XM

|

4130

|

1717COS110

|

SCM420

|

30CD4

|

|

||||||

|

42CrMo

|

|

4140

|

708A42

|

|

42CD4

|

42CrMo4

|

||||||

|

|

|

|

708M40

|

|

|

|

||||||

|

35CrMo

|

35XM

|

4135

|

708A37

|

SCM3

|

35CD4

|

34CrMo4

|

||||||

Applications

1. For Vehicle (Automotive, locomotive, Construction Machinery like Concrete pump and others)

Power steering system, Shock absorber, vibration damper , engine parts and others

2. Hydraulic cylinder, Industry Jacks

3. Fitness equipment,motor casings and auto parts.

Other precision surface required devises

Power steering system, Shock absorber, vibration damper , engine parts and others

2. Hydraulic cylinder, Industry Jacks

3. Fitness equipment,motor casings and auto parts.

Other precision surface required devises

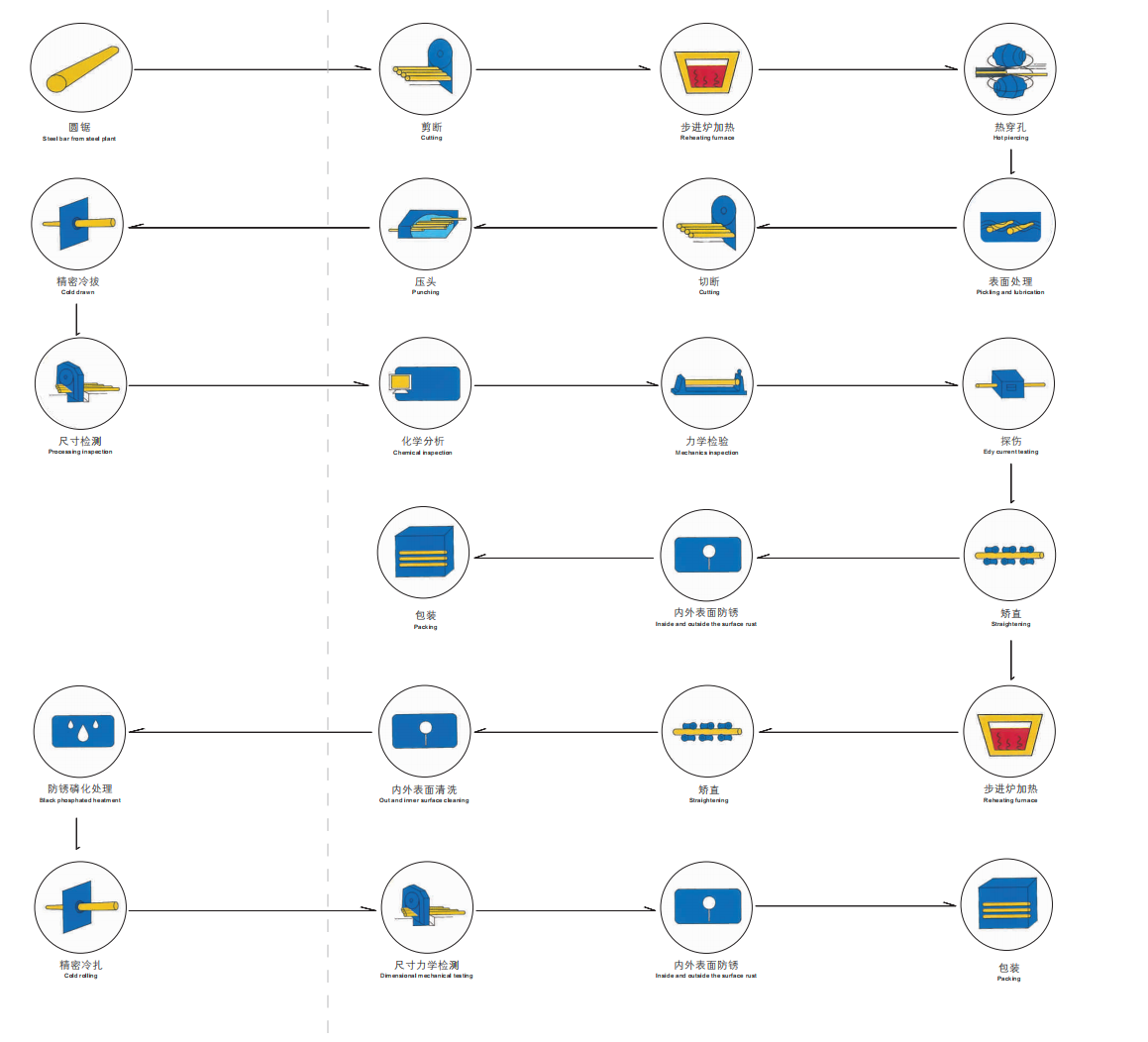

Manufacture Process:

Packing & Delivery

Hot Searches