Gas fired heating system Continuous walking beam type

Maximum temperature: 1100°C

With preheating and soaking zones Low surface oxidation

Automatic cylinder charging and discharging tables

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8900*1920*2900mm

-

Weight (T):

-

10 T

-

Power (kW):

-

160

-

Application:

-

Tempering

-

Suitable Metal:

-

37Mn 30CrMo 34CrMo4

-

Max temperature:

-

1200.C

-

Fuel used:

-

CNG Diesel LPG

-

Heating method:

-

Induction Method

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HS

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

8900*1920*2900mm

-

Weight (T):

-

10 T

-

Power (kW):

-

160

-

Application:

-

Tempering

-

Suitable Metal:

-

37Mn 30CrMo 34CrMo4

-

Max temperature:

-

1200.C

-

Fuel used:

-

CNG Diesel LPG

-

Heating method:

-

Induction Method

Product Description

Consider different requirements, we mainly prompt two machine configuration 100 cylinders/8hrs & 300 cylinder/8hrs which could be selected by customers to fit for the budget.The line is comprised of three main parts :

1- Hardening furnace

2- Automatic quenching tank

3- Tempering furnace

Capable of charging CNG cylinders in different sizes and weights

Continuous with adjustable motion pace

Gas fired heating system

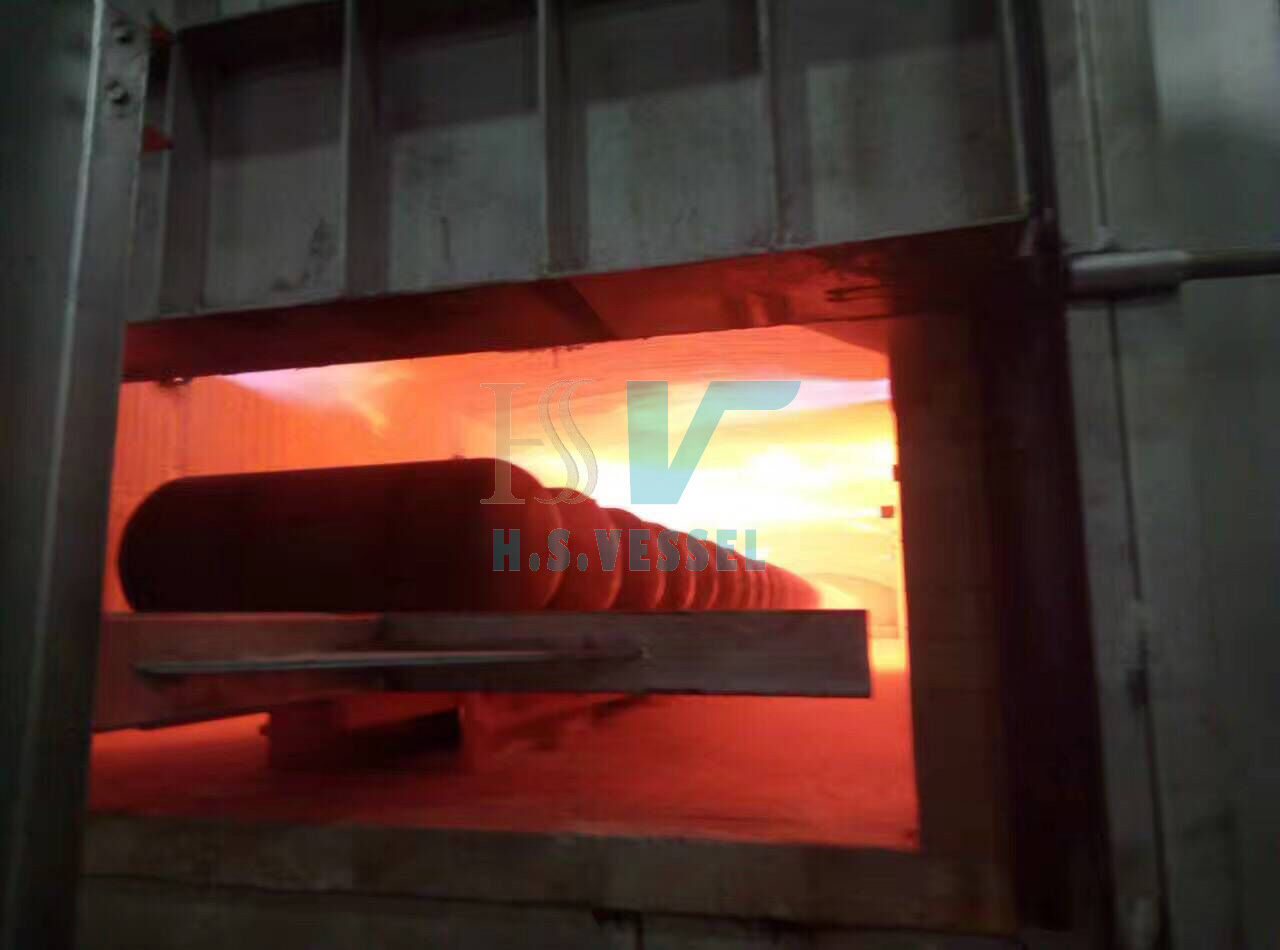

No direct contact of flame with the surface of treated parts

1- Hardening furnace

2- Automatic quenching tank

3- Tempering furnace

Capable of charging CNG cylinders in different sizes and weights

Continuous with adjustable motion pace

Gas fired heating system

No direct contact of flame with the surface of treated parts

Hardening Furnace

Automatic Quenching Tank

Automatic immersion and extraction of the cylinders Affording various quenching methods

Equipped with the cooling and heating systems Suitable agitation inside the quenching tank

Equipped with the cooling and heating systems Suitable agitation inside the quenching tank

Tempering Furnace

Gas-fired heating system

Continuous movement with conveyor or walking beam systems

Hot air circulation system to reach to the best thermal uniformity

Maximum operating temperature of 750°C

Including preheating and soaking zones with excellent thermal uniformity

No direct flame contact with treated parts

PLC-controlled Automation & Monitoring System

Capabilities of this system are:

Temperature control and display of actual and set temperatures graphs in each zone

Display of burners status

Display of temperature graphs for each zone (Temperature-Time graph)

Data recording such as temperature, pressure, ...

Display of doors status

Display of system motion performance

Display of motor fans mode (On/Off)

Display of PLC operation option (Manual/Automatic)

Alarming in cases of air pressure drop, gas pressure?drop/rise, temperature rise in each zone, burner turn off and PLC malfunction

Temperature control and display of actual and set temperatures graphs in each zone

Display of burners status

Display of temperature graphs for each zone (Temperature-Time graph)

Data recording such as temperature, pressure, ...

Display of doors status

Display of system motion performance

Display of motor fans mode (On/Off)

Display of PLC operation option (Manual/Automatic)

Alarming in cases of air pressure drop, gas pressure?drop/rise, temperature rise in each zone, burner turn off and PLC malfunction

|

356mm W.B. Type

|

|

|

||

|

Fuel name

|

Natural gas

|

|

||

|

Rated combustion power

|

1080KW

|

|

||

|

Rated air consumption

|

about 109Nm3/h

|

|

||

|

The number of burners

|

6 (one for each area on the left and right)

|

|

||

|

Temperature control accuracy

|

±2ºC

|

|

||

|

Furnace temperature uniformity

|

±10°C (holding section)

|

|

||

|

The distance between the steel cylinders in the furnace

|

390mm

|

|

||

|

Process time

|

70min

|

|

||

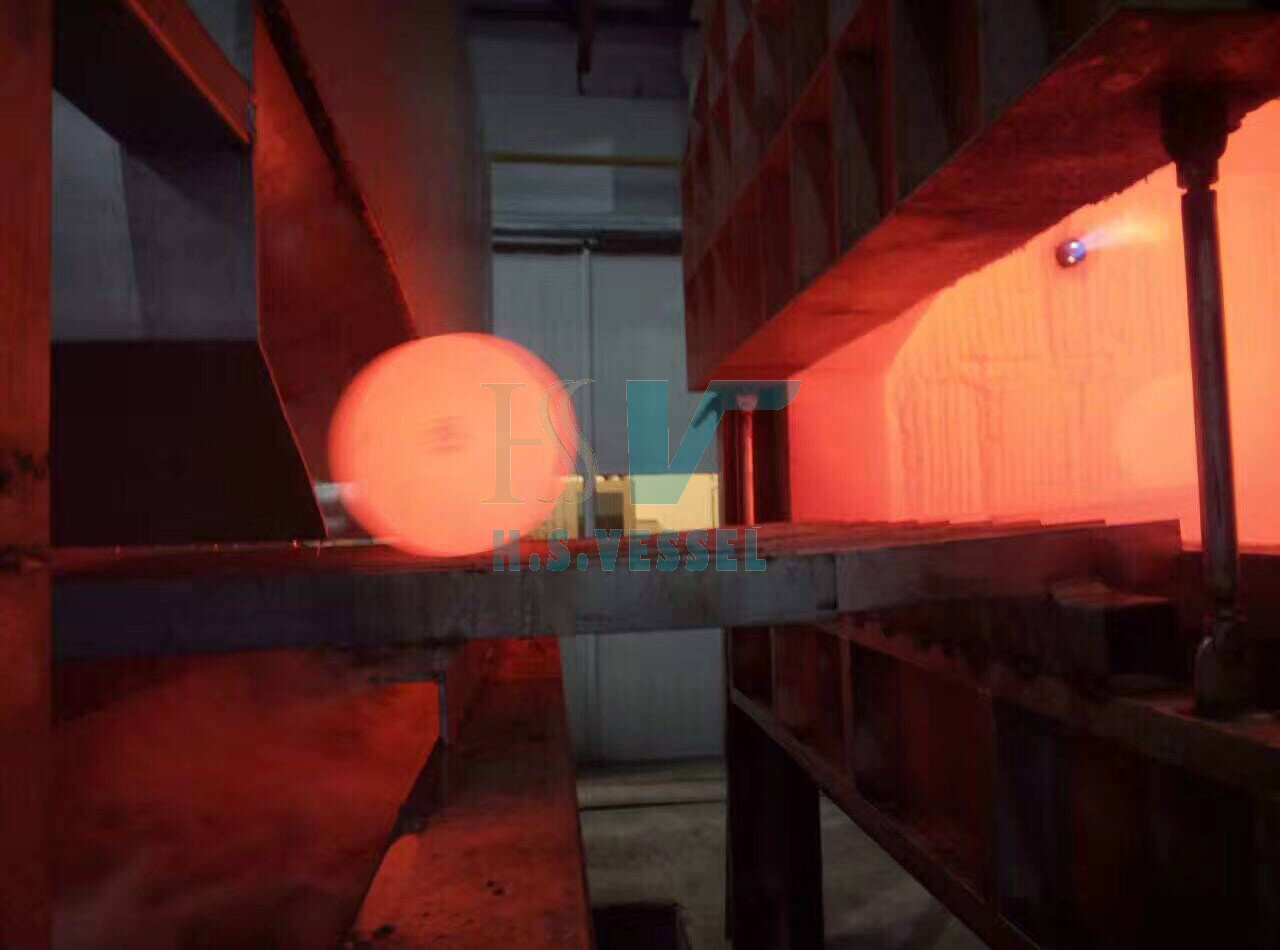

Machine Using In Client's Factory

Hot Searches