- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

50KW

-

Dimension(L*W*H):

-

customized

-

Application:

-

Casting Industries

-

Type:

-

Horizontal

-

Material:

-

steel

-

Usage:

-

Foundry Pieces

-

Product name:

-

Continuous Casting Machine

-

Name:

-

Resin Sand Production Line

-

Feature:

-

Professional

-

Raw material:

-

iron steel

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Weight:

-

customized

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

foundry machine

-

Brand Name:

-

BESTECH

-

Voltage:

-

380V

-

Power:

-

50KW

-

Dimension(L*W*H):

-

customized

-

Application:

-

Casting Industries

-

Type:

-

Horizontal

-

Material:

-

steel

-

Usage:

-

Foundry Pieces

-

Product name:

-

Continuous Casting Machine

-

Name:

-

Resin Sand Production Line

-

Feature:

-

Professional

-

Raw material:

-

iron steel

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Weight:

-

customized

-

Certification:

-

CE ISO

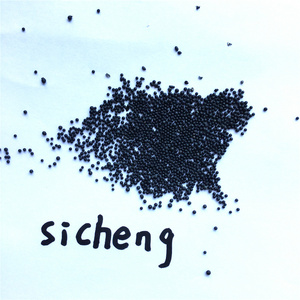

Introduction of resin sand processing production line

This production line,to resin sand as material, use of molding machine making sand mould and pour molten iron in to sand mould,the last generate workpiece. The resin sand is mixed of natural silica sand, resin and hardener. The whole line compose of sand reclamation system and molding system. Sand reclamation system which is used sand after crushing, screening to use again. Molding system is put the mixture of resin sand fill in the molding machine, generate sand mould for pouring.

Main equipments introduction

1. Belt conveyor

This conveyor is a new type designed according to the special application of casting plant. It is mainly used

for conveying the new sand, used sand, molding sand, coat and lime stone as well as the construction material,chemical industry and food processing for all granular or block shape material.

2. Multi-function vibration regenerator

This regeneration machine is designed for the resin sand or silicate bonded sand regeneration. The main

mode is vibration and friction regeneration, also the function of breaking sand shakeout, sieving, demold.

3. Bucket elevator

This machine is a vertical transferring machine which is applied in mechanical casting plant. It is mainly use

for elevating the used sand, waste sand, new sand, cleaning iron shot, etc. Combined with the belt conveyor

and other devices, we can design many kind of transferring system. The features are small external size, less volume and higher elevation level so that the layout drawing will be compact.

4. Centrifugal regenerator

The centrifugal machine adopts the principle of dry process centrifugal regeneration. It is mainly used for used resin sand regeneration. The used sand will be

thrown to wearresisting lining by the high speed rotating blade. And the inert cover on the surface of resin sand will be removed by the rub and collision process between the sand articles, blade and box. According

to the process requirement, the process will be repeated for many times till the target achieved.

5. air-float separator

The separator is mainly used for separating the powder from the sand of resin sand and sodium silicate sand.The powder should be completely removed from regenerating sand, so that the regenerating sand may meet the process requirement.

6. Double-arm sand mixer

The machine is applied to mix the resin sand and silicate bonded sand. The adhesive feeding system

consisted of the gear pump, membrane pump and liquid detector so the measurement is accurate, the mixing

period is short and the loss of first and last round sand is less. The doublearm of machine rotates flexibly and the available working area is large. The open type sand mixing stir cage is advantage for cleaning or adjusting the blade. The dust collection and deflavour system are combined in the primary and secondary connection as well as the secondary outlet, in order to reduce the content of powder and binder air in the sand. The electric control system is PLC controlled and completely restricting protection. The information displayed by mimic board with reliable operation.

7. Sand temperature regulator

The main principle of sand temperature regulator: The sand is conveyed to sand temperature regulator

from the top of sand temperature regulator and there are water pipes in the sand temperature regulator.

The cooling water or hot water continuously flow in the heat sink which assembled with multilevel cooling pipes. Hot sand or cold sand is conveyed to from the water pipes for heating exchange. The sand will be conveyed out when reach the set temperature

8. Dust collector

Dedust the workshop and operation equipment.

All the equipments can is designed according to customer's requirement.

1. Reply your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in fluent English.

3. Customized design is available. UEM&UBM are welcomed.

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5. Special discount and protection of sales are provided to our distributor.

6. Professional factory : We are manufacturer, specializing in producing all kinds of machinery for more than 20 years, competitive with good quantity.

7. Sample: We can send out sample for test in one week if the order quantity is big enough. But the shipment charges is usually paid by your side, the charges will be rebounded when we have formal order.

8. As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. Welcome to contact us or visit our company.