- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PCB300

-

Power:

-

95.9

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

5000 kg

-

Key selling points:

-

Automatic

-

Raw material:

-

Electronic Waste

-

Voltage:

-

220 v/380 v/customized

-

Product Name:

-

E-waste Recycle Machine

-

Color:

-

customer requirement

-

Separation rate:

-

99%

-

Function:

-

E-waste Recycle Machine Scrap Metal Computer Board Recycle Machine

-

Application:

-

PCB recycling

-

Final product:

-

Resin powder and copper powder

-

Advantage:

-

High separation rate

Quick Details

-

Production Capacity:

-

200-300kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

VANEST

-

Model Number:

-

PCB300

-

Power:

-

95.9

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

5000 kg

-

Key selling points:

-

Automatic

-

Raw material:

-

Electronic Waste

-

Voltage:

-

220 v/380 v/customized

-

Product Name:

-

E-waste Recycle Machine

-

Color:

-

customer requirement

-

Separation rate:

-

99%

-

Function:

-

E-waste Recycle Machine Scrap Metal Computer Board Recycle Machine

-

Application:

-

PCB recycling

-

Final product:

-

Resin powder and copper powder

-

Advantage:

-

High separation rate

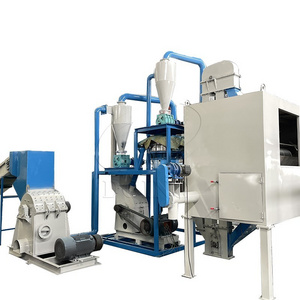

WASTE PCB RECYCLING PLANT

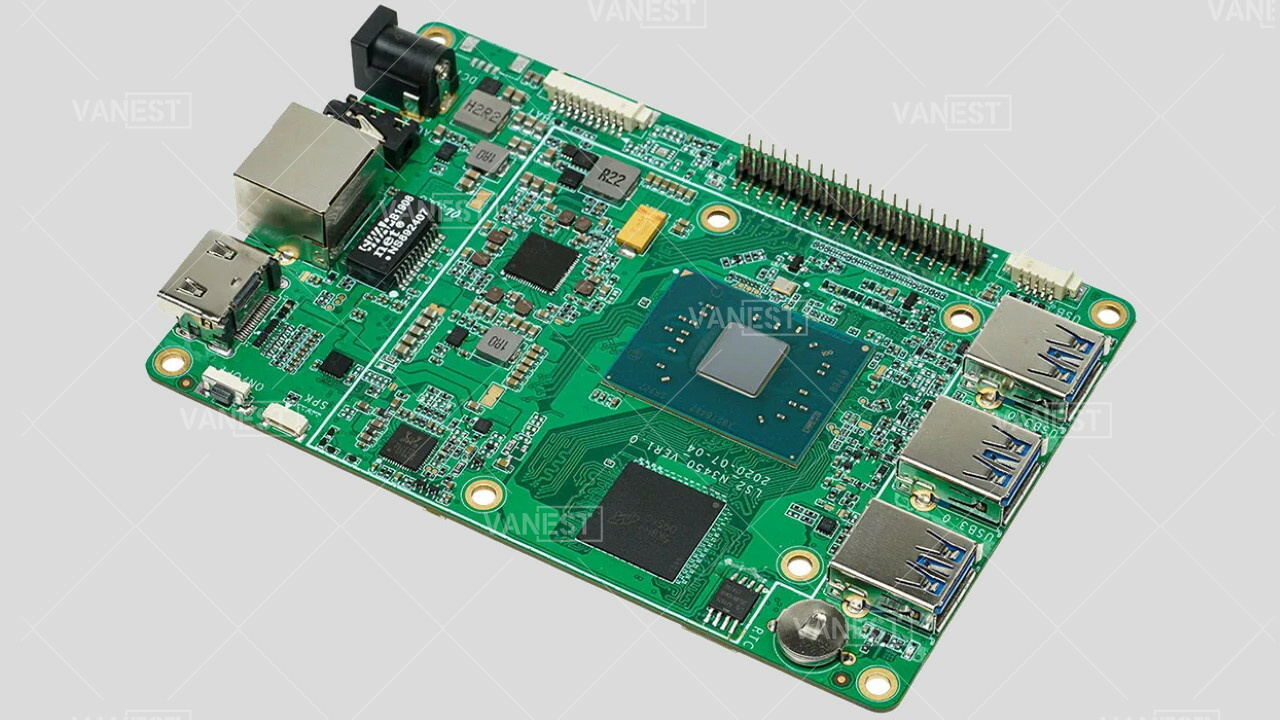

PRODUCT APPLICATION

Waste PCB Recycle Plant is used to recycle all kinds of Printed Circuit boards, such as the computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances, and the separation of leftover material of the mixed metal and nonmetal materials.

RAW MATERIALS

FINAL PRODUCTS

Because of the high value of the metals, fiber and resin, there is no doubt that this plant not only help to change waste into treasure, but also bring great economic benefits.Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

Working Process Flow of PCB Recycling Machine

● PCB dismantling machine: The dismantling and separation of the substrate and electronic components of various scrapped home appliance circuit boards.

● No.2 crusher: further crush the material to about 0.3 mm.

● Dust collect: the dust, microfiber generated during crushing is collected.

● PCB dismantling machine: The dismantling and separation of the substrate and electronic components of various scrapped home appliance circuit boards.

● First shredding:

Shred raw material into 5-6 cm.

●

No.1 crusher: crushing circuit boards into 3 mm.

● No.2 crusher: further crush the material to about 0.3 mm.

● Spin vibration sieve :

Spin vibration sieve: Two layer sieves, separate big mixed mash and smaller mixed mash.

The bigger mixed mash will return to No.2 crusher, the smaller mash reach into the high-voltage electrostatic separator.

● Electrostatic Separator:

The separation effect of the electrostatic separator is as high as 99.99%, which is a complete physical separation. The plastic and fiber and copper are separated by electrostatic principle.

● Dust collect: the dust, microfiber generated during crushing is collected.

|

MODEL

|

PCB150

|

PCB300

|

PCB700

|

PCB1100

|

PCB1500

|

PCB4000

|

||||||

|

CAPACITY (kg/h)

|

100-150

|

200-300

|

600-700

|

800-1100

|

1100-1500

|

3500-4000

|

||||||

|

POWER (kw)

|

46.8

|

95.9

|

156.2

|

234.8

|

308.1

|

499.3

|

||||||

|

Note: * Working voltage:380V, 415V ,440V or can be customized.

For more detailed parameter or quotation, please contact our salesman.

|

|

|

|

|

|

|

||||||

PCB RECYCLING MACHINE SHOW

DISMANTLING MACHINE

PCB RECYCLING LINE

Hot Searches