- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

different models

-

Weight:

-

350 KG

-

Warranty:

-

2 years

-

Marketing Type:

-

NEW

-

Core Components:

-

Main parts

-

Name:

-

small amalgamation barrel

-

Application range:

-

Gold, silver, copper, platinum etc

-

Color:

-

Customerized

-

Processed Materials:

-

Gold

-

Certification:

-

ISO

Quick Details

-

Production Capacity:

-

20-100kgs/h

-

Place of Origin:

-

China

-

Voltage:

-

1.1-3kw

-

Dimension(L*W*H):

-

different models

-

Weight:

-

350 KG

-

Warranty:

-

2 years

-

Marketing Type:

-

NEW

-

Core Components:

-

Main parts

-

Name:

-

small amalgamation barrel

-

Application range:

-

Gold, silver, copper, platinum etc

-

Color:

-

Customerized

-

Processed Materials:

-

Gold

-

Certification:

-

ISO

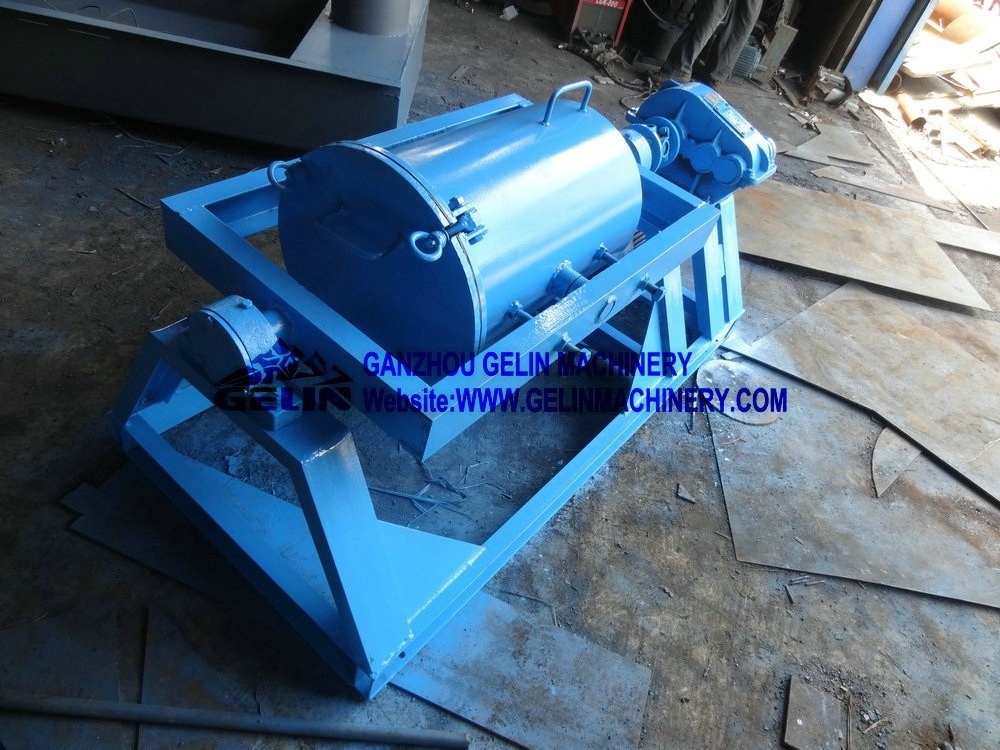

Tube Type and V type gold amalgama barrel refining machine for extracting pure gold

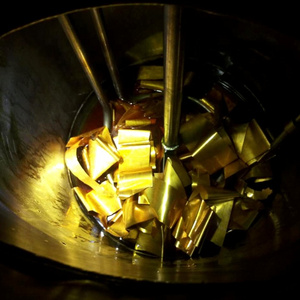

Gold mercury amalgam barrel

is the traditional gold refining machine,it's been widely used to mix the mercury and gold

concentrate from shaking table, sluice box or gold concentrator and finally to get the pure gold from black sand.

Our

automatic mercury amalgamator

is newly designed with stainless iron barrel and motor to drive,this machine is used for mixing the mercury and gold with black sand, get the gold amalgam. Then distill the gold amalgam in the mercury retort and get the pure gold.

Gelin provides 2 different types for customers.

1.

Amalgamation Cylinder Gold Extraction Machine

is

a type of internal amalgamating equipment that is widely used in gold processing plant, is used to process heavy sand containing gold of gravel mine and gold concentrate of vein gold mine, presenting a gold recovery rate of higher than 98%.

Features

1. High recovery ratio more than 98% The loss rate of mercury

2. Total process automation, steady recovery performance

3. Center discharge design for fast, secure removal

4. Environmentally (requires no release mercury)

5. Low water and electricity requirements

6. Low production costs, durable wear parts, minimal maintenance requirements

7. Compact design requiring less space, easy merged into the existing mining processing

8. Quick payback on investment, typically lass than half year

9. Movable ,easy to move

|

Specification

|

|

|

||

|

Model

|

380*600

|

400*1000

|

||

|

Capacity (t/h)

|

20-50Kg

|

80-100Kg

|

||

|

Power (kw)

|

0.55KW

|

1.1KW

|

||

|

Drum diameter (mm)

|

380

|

400

|

||

|

Drum length (mm)

|

600

|

1000

|

||

|

Feeding size (mm)

|

≦10

|

|

||

|

Output size (mesh)

|

200-300

|

|

||

|

Application

|

Gold,silver,copper,platinum.

|

|

||

|

Dimension (mm)

|

1650*450*750

|

2750*650*850

|

||

|

Weight (kg)

|

350

|

650

|

||

2. V-Type Amalgamator was newly designed with a nice outcome. It’s really good for particulate with good fluidity or powder. Degree of mixing could reach to 97% to 98%. It is widely used for chemical, medicine and light industry.

Features

1. Barrel is usually made by stainless steel. Its inner and outer are all polishing. From its structure, we could ensure no dead space for remains and easy to rinse thoroughly. It contains three ports, partly for feeding, maintenance and discharging. We provide customized service if you have any other requirement on material quality. Its frame is welded by nice carbon steel and wrapped with sheet iron.

2. Its rotating time could be controlled, and then it will stop.

3. This equipment should be put on the horizontal cement floor. It should be fixed by foundation screw to ensure its smooth operation. Check the jog running. Make sure no leakage.

|

Specification

|

|

|

|

|||

|

Model

|

Power (kw)

|

Volume(L)

|

Effective volume(L)

|

|||

|

V-50L

|

2.2

|

50

|

20

|

|||

|

V-100L

|

3

|

100

|

40

|

|||

3. Attached: Amalgam retort for separating gold from mercury

The Gold Amalgamator Machine is used to mix the gold concentrates and mercury so that the mercury will wrap the gold. Then we will get the gold amalgam.

The next process after the amalgamator is to distill the gold amalgam in the

amalgam retort

so as to separate the gold from mercury, during which we could get the pure gold and recover the mercury for re-using.

Due to mercury gasification temperature is below the melting point and boiling point of gold. We commonly used the method of distillation to separate the gold from amalgam mercury.

Working Principle

1. Put the amalgam mercury mix with gold into the sealed mercury distiller.

As there is a condenser tube connected with the top of the distiller;

2. Heat the distiller on the coke, gas or electric furnace;

3. When the temperature reached 356°C, the amalgam will gasification, the Hg gas will run out through the iron tube;

4. The gas Hg will become spherical droplets after go through the condenser tube, and then you can recycle the Hg.

5. In order to separate the Hg completely, gold mining plant usually maintained the temperature on 400-450°C. And in the last 30 minutes, raised the temperature to 750-800°C.

6. Distill the Hg for around 5-6hours, the gold recovery rate can reach 99%.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

A: By TT( Telegraphic Transfer ) , 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

Q: How long is the guarantee period of your products?

A: Yes, most of our products are produced as required.

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.