Performance Characteristics:

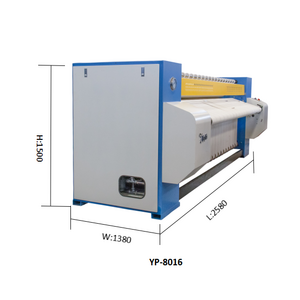

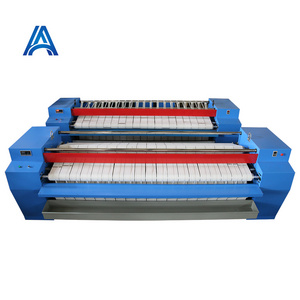

1. The roller is made of high quality stainless steel, the surface is processed by grinding, so that the wear of the fabric is reduced to the minimum. The chassis and the auxiliary roller are welded with high quality carbon structure, which is strong and durable.

2. All the sub-rollers are galvanized to improve the corrosion resistance of the machine. Variable frequency speed regulation is adopted to adjust the speed flexibly, stably and with low noise.

3. The main roller and the auxiliary roller adopt differential design to effectively improve the flatness of ironed fabric. Direct heat main roller, the effective heating area more than 75%, improve the energy efficiency, reduce the labor intensity of the operating workers.

4, the use of frequency converter speed control, according to the need to adjust the ironing speed. Smooth operation, energy saving.

5, big corner ironing structure, to the maximum extent to improve the ironing area, full use of heat energy, low energy

consumption.

6, equipped with overload protection, emergency brake, safety protection device, protection, machine safety.

7, quick ironing belt adjustment device, easy to adjust. Iron cylinder made of stainless steel, long service life.

8. New and unique structure, high ironing quality, easy operation and low operating cost.