- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

OEM

-

Dimension(L*W*H):

-

According to drawings

-

Weight:

-

250 kg

-

Product Name:

-

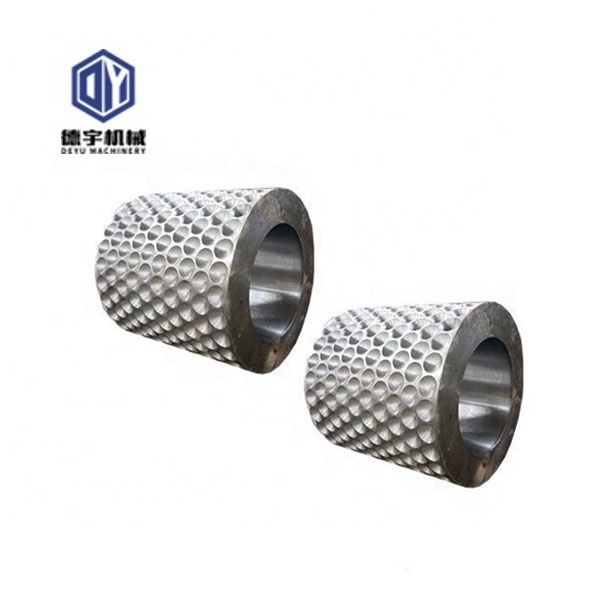

Steel crusher roller shell mining machine pellet parts roller sleeve

-

Application:

-

Steel factory, Rolling Mill etc.

-

Size:

-

OD max to 1500mm

-

Processing:

-

CNC Turning

-

Surface treatment:

-

Polishing/Grinding/ Painting/Anti Rust Oil

-

Heat Teatment:

-

QT/Hardening/Carburizing

-

Blank:

-

Casting/Forging as per drawing

-

Quality Control:

-

NDT test

-

Certificate:

-

ISO9001

-

OEM:

-

drawing design

Quick Details

-

Max. Capacity:

-

8 ton/h

-

Place of Origin:

-

Henan

-

Brand Name:

-

DE YU

-

Voltage:

-

OEM

-

Dimension(L*W*H):

-

According to drawings

-

Weight:

-

250 kg

-

Product Name:

-

Steel crusher roller shell mining machine pellet parts roller sleeve

-

Application:

-

Steel factory, Rolling Mill etc.

-

Size:

-

OD max to 1500mm

-

Processing:

-

CNC Turning

-

Surface treatment:

-

Polishing/Grinding/ Painting/Anti Rust Oil

-

Heat Teatment:

-

QT/Hardening/Carburizing

-

Blank:

-

Casting/Forging as per drawing

-

Quality Control:

-

NDT test

-

Certificate:

-

ISO9001

-

OEM:

-

drawing design

The press roller shell, commonly known as the press roller, is one of the main working parts of the pelletizer. It is used to

process various biofuels, animal feeds and other pellets. Our company can customize different sizes and shapes of press rolls according to your requirements or provided drawings or samples.

Material:

Advantages:

Customized Capabilities

|

Diameter

|

≤1500mm

|

|

Length

|

≤4200mm

|

|

Technical

|

casting/ forging/cnc machining

|

|

Surface Hardness

|

as per different material

|

|

Heat Treatment

|

quenching and tempering ,carburization ardening

|

Packing Details : Wooden box with fumigation or Wooden Fram

Delivery Details : 30~60days or Based on the quantity

1. Anti-Rust Oil

2. Air Bubble Film

3. Wooden Box with fumigation

1.Anti-Rust Oil

2.Waterproof plastic cloths

3. Fram

Q: Are you trading company or manufacturer ?

A: We are factory, specializing in making all kinds of heavy machine spare parts machining.

Q: How long is your delivery time?

A: Generally it is 30~45 days. or it is according to quantity and technical requirement

Q: Do you provide the production video and photos

A: Yes, we could send you the processing photos or videos during production to follow up the production time

Q: Do you provide checking report

A: yes, we could provide you the checking report as follows:

1) Dimensions checking report

2) Material certificate

3) Heat treatment report

4) NDT test report (UT/MT/PT)

5) Mechanical property report

6) Other report by the customer

If you have another question, please feel free to contact us as below