- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SIECC

-

Year:

-

2022

-

Voltage:

-

Customer-Oriented

-

Dimension(L*W*H):

-

1100X1200X1700MM

-

Weight (T):

-

9000 T

-

Motor Power (kw):

-

13 kw

-

Marketing Type:

-

Hot Product 2022

-

CNC or Not:

-

CNC

-

Power Source:

-

Hydraulic

-

Certification:

-

CE/ISO/SGS/GOST

Quick Details

-

Machine Type:

-

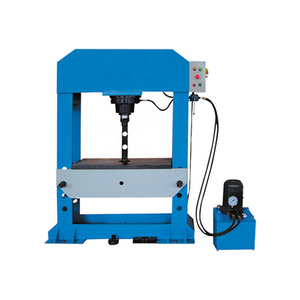

Four-column Three-beam Hydraulic Press

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SIECC

-

Year:

-

2022

-

Voltage:

-

Customer-Oriented

-

Dimension(L*W*H):

-

1100X1200X1700MM

-

Weight (T):

-

9000 T

-

Motor Power (kw):

-

13 kw

-

Marketing Type:

-

Hot Product 2022

-

CNC or Not:

-

CNC

-

Power Source:

-

Hydraulic

-

Certification:

-

CE/ISO/SGS/GOST

|

ü THE MAIN DISCRIPTION |

|

SIECC has been in machine industry field for about 10 years, we produce and sell all kinds of NC/CNC press brake, 3 or 4 roller rolling machine, high quality shearing machine including swing beam and various rank guillotine shears, hydraulic press , lathe machine, milling machine etc. All machines are under CE certification and experienced in the market of European such as United Kingdom, Belgium, Romania, Hungary, Croatia and also all the other countries in the world. We produce about 40 sets of press brake machine monthly. In this large production volume, therefore enable us to be a price-effective in manufactory cost level. We consist in financial flexible principle to collaborate with our partner for a better recovery cost after their investment. We also provide client-oriented after-sale service with engineer available if needed. In any cases, our action is in rapid response, immediately action in both consultation or site guidance. The machine WC67Y (or in this paper) is torsion bar synchronization NC/CNC press brake, compact in structure ,easy in operation adjustment ,stable in usage and high precision synchronization. |

|

ü THE MAIN CHARACTER |

|

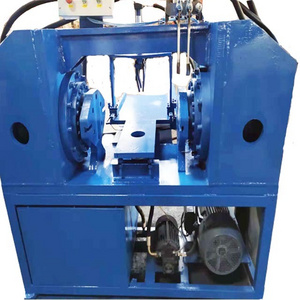

This machine is suitable for precise straightening technology on shaft parts ,widely used in automobile , tractor, household appliances, textile manufacturing machine, lathe machine ‘s straightening procedure. |

|

ü THE STANDARD COMPONENTS |

|

1. ELECTRONIC COMPONENTS: SIEMENS 2. OIL PUMP: QIDONG HIGH-PRESSURE 3. MOTOR: JIANGSU HENGLI 4. VALVE: REXROTH OR USA OMG 5. SEAL : USA PARKER 6. STEEL: SHANGHAI BAO STEEL |

|

ü OPTIONAL COMPONENTS OR DESIGN |

|

1. REQUIRED DESIGNABLE STROKE 2. REQUIRED DESIGNABLE WORKING TABLE 3. REQUIRED DESIGNABLE DAYLIGHT |

|

ü MAIN STRUCTURE |

|

The machine use single column C type integrated type. The machine body is done through Q235A Steel under carbon dioxide welding production. After the welding ,there are vibration aging treatment to relieve the welding stress. There are T type block for convenient mold equipment and fix The Main press is got through a single cylinder. Cylinder and piston rod adopt the high quality carbon steel forging. The piston rod are processed under hardening and through chrome surface treatment ,so it is possible for longterm usage anti-rust treatment. The main cylinder adopt high quality seal inside to ensure no any leakage.

The hydraulic system adopt advanced cartridge valve control system , high speed action ,easy in maintenance. There are filter inside the hydraulic system , temperature control relay, air cleaner. The hydraulic oil tank inside the machine body for space-saving and good outside appearance. |

|

n THE ELECTRONIC CONTROL SYSTEM |

|

There are independent electronic box equipped at the right side for the main machine The machine has one operation panel to achieve the operation to the press machine. There are one active button station for the basic operation of the machine. The operation type is manual and semi-automatic. Exclude from all the working procedure for the press ,there are also button of “ two-hand press”, “Beam Return”,”Stop”,”emergency stop”. |

|

n SECURITY OF EQUIPMENT |

|

Two hands to operate the buttons. Emergency button: When there are some emergency, press the emergency button to stop working. Overload protection: There are hydraulic security valve in the hydraulic system to ensure the machine will not be overloaded. Hydraulic support safety circuit: At the bottom of piston cylinder ,there are hydraulic safety circuit and be locked with the up cavity circuit of the main cylinder to ensure the life-valve not open and the up cavity of the main will not up press. |

|

ü DIES TOOLS |

|

THE MACHNE PRICE HAS NOT INCLUDED THE DIE TOOLS. WE RECOMMEND YOU TO PRODUCE THE DIES IN YOUR DESTINATION FACTORY BECAUSE THE DIES ARE QUICK-WEAR PARTS. WE CAN DESIGN FOR YOU ALSO IF NEEDED. THE DRAWING IS REQUIRED. |