- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight (KG):

-

2225

-

Power (kW):

-

55

-

Production capacity:

-

1-10 tons per hour by single machine

-

Raw material humidity:

-

20%-40%

-

Feeding size:

-

Powder

-

Output humidity:

-

As per raw material

-

Granules size:

-

2-5mm

-

Installation:

-

Offer overseas installation and online guidance

-

Operation:

-

Offer operation training

-

Spare parts:

-

Supplied

-

Production line:

-

CAD or 3D

-

Delivery:

-

Delivery Shipping, railway, land transportation

Quick Details

-

Output (kg/h):

-

1-10 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Tianci

-

Voltage:

-

380V

-

Weight (KG):

-

2225

-

Power (kW):

-

55

-

Production capacity:

-

1-10 tons per hour by single machine

-

Raw material humidity:

-

20%-40%

-

Feeding size:

-

Powder

-

Output humidity:

-

As per raw material

-

Granules size:

-

2-5mm

-

Installation:

-

Offer overseas installation and online guidance

-

Operation:

-

Offer operation training

-

Spare parts:

-

Supplied

-

Production line:

-

CAD or 3D

-

Delivery:

-

Delivery Shipping, railway, land transportation

Animal manure poultry manure chicken manure harmless treatment granules making machine fertilizer machine

-- Product Description --

It is designed and manufactured by a new process of wet continuous push rod granulation. This machine can not only granulate a variety of organic matter, especially coarse fiber materials that are difficult to granulate with conventional equipment. The granules are spherical, and the organic content is as high as 100%, and no binder is added during granulation. The particles are firm and can be screened after granulation, and the moisture content of the raw materials can be about 20%-40%.

-- Organic Fertilizer Granulator --

Usage: Used in the production of organic fertilizer granular.

Production Capacity: 1-20t/h.

Raw Materials: Chicken Manure, cow dung, animal waste and so on.

Granular Shape: Round shape.

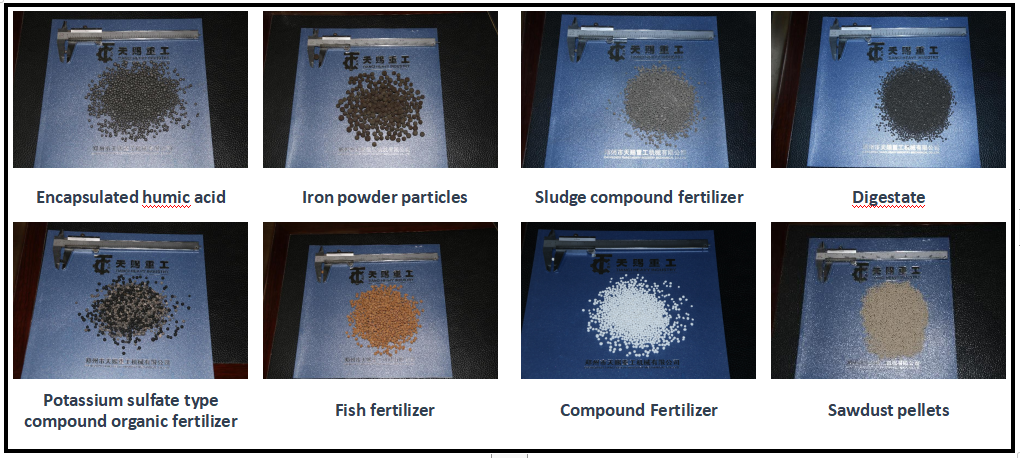

-- Adaptable objects --

1. Agricultural organic waste (compost, liquid fertilizer) treatment.

2. Food waste organic waste (swill) treatment, food waste and manure.

3. There is a lot of farmyard manure.Such as human excrement, livestock excrement, green manure, compost and retting fertilizer, etc.

4. Bio-organic fertilizer starter, bio-fertilizer starter, organic fertilizer decomposition agent, fertilizer microbial preparation, agricultural organic waste (compost, liquid fertilizer) treatment, kitchen waste organic waste (swill) treatment, various crop straws, melons and vines , livestock and poultry manure, leaves and weeds, bran vinegar residue, wine residue, vinegar residue, soy sauce residue, bean cake, residue, meal residue, tofu residue, bone meal, bagasse and other wastes can be quickly turned into bio-organic fertilizers.

-- Characteristics of Performance --

* The observation window can be used to observe the working situation at any time;

* Wheels on both sides can increase power and reduce energy saving;

* The screw in the middle can be opened directly, reducing maintenance costs;

* The stirring tooth structure inside the machine can speed up the working efficiency of the machine.

Main Technical Parameters & Specifications:

|

Model |

Granulation Method |

Production Capacity |

Motor Power(Kw) |

Feeding Humidity |

Output Humidity |

Granules Shape&Size |

|

YSL-60 |

Wet granulation |

1-2t/h |

30 |

20%-40% |

15%-18% |

Round ball 3-5mm |

|

YSL-80 |

Wet granulation |

2-4t/h |

45 |

20%-40% |

15%-18% |

Round ball 3-5mm |

|

YSL-100 |

Wet granulation |

4-6t/h |

55 |

20%-40% |

15%-18% |

Round ball 3-5mm |

|

YSL-120 |

Wet granulation |

6-8t/h |

75 |

20%-40% |

15%-18% |

Round ball 3-5mm |

-- Working Principle --

The new type organic fertilizer granulator uses high speed rotating mechanical shearing force and the resulting air power, making continuous implementation of the fine powder material in the machine mixing, granulating, spheroidizing, density and other processes, which achieves the goal of the granulation. The granulation method makes the pellet rate higher, and the granule is more beautiful, while saving energy and improving efficiency.

How can I chose a proper model?

1-What is your raw material, how many kinds of them in total?

2-How many millimeter the granules size that you need?

3-The target production capacity per day or per year?

Please leaving message below, we will provide clear specification and design soon.

-- Delivery --

--