1.Electrical signal control intensifier reversing

2.Programmable logic controller and PLC

3.Full-automatic NC system cutting

4.WYE-DELTA soft start

5.UHP Manos tat and filter

6.Safety shutdown and protective device

7.Automatic temperature control cueing system

8.Accurate localization device at shot range

9.Fault alarm

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

100

-

Marketing Type:

-

Hot Product 2023

-

Cutting Accuracy(mm):

-

±0.001

-

Brand Name:

-

JX AUTO CNC Waterjet water jet cutter

-

Voltage:

-

380V

-

Rated Power:

-

37KW/50HP

-

Dimension(L*W*H):

-

1620mmx1580mmx1360mm

-

Year:

-

2023

-

Weight (KG):

-

1050 KG

-

Working pressure:

-

320~360Mpa

-

Maximum pressure:

-

413Mpa(60000psi)

-

Axial Plunger pump:

-

Hengyuan

-

Hydraulic system:

-

Sunny/Yuken

-

Inductive sensor:

-

Contri-nex

-

Hp Cylinder:

-

BATA

-

Check tube assembly:

-

JX AUTO CNC

-

Oil Cylinder:

-

BATA

-

HP seal kits:

-

BATA

-

keyword:

-

Waterjet water jet cutter cut Cutting Machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Table Travel (X) (mm):

-

1300

-

Table Travel (Y) (mm):

-

1300

-

Table Travel (Z) (mm):

-

100

-

Marketing Type:

-

Hot Product 2023

-

Cutting Accuracy(mm):

-

±0.001

-

Brand Name:

-

JX AUTO CNC Waterjet water jet cutter

-

Voltage:

-

380V

-

Rated Power:

-

37KW/50HP

-

Dimension(L*W*H):

-

1620mmx1580mmx1360mm

-

Year:

-

2023

-

Weight (KG):

-

1050 KG

-

Working pressure:

-

320~360Mpa

-

Maximum pressure:

-

413Mpa(60000psi)

-

Axial Plunger pump:

-

Hengyuan

-

Hydraulic system:

-

Sunny/Yuken

-

Inductive sensor:

-

Contri-nex

-

Hp Cylinder:

-

BATA

-

Check tube assembly:

-

JX AUTO CNC

-

Oil Cylinder:

-

BATA

-

HP seal kits:

-

BATA

-

keyword:

-

Waterjet water jet cutter cut Cutting Machine

Products Description

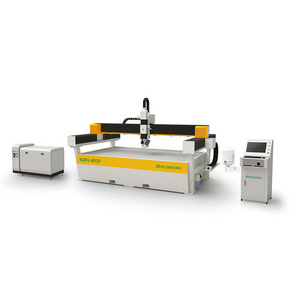

1313 SERIES WATERJET CUTTING MACHINE 50HP

The JX—1313 CNC waterjet cutting series is an addition to Accurl JX—1313 CNC waterjet cutting machine line. It provides a vigorous industrial design and rigid construction that combines precision and simplicity.

The

JX—1313

model is made to handle high production for versatile applications.

The

JX—1313

waterjet cutting series provides a vigorous industrial design and rigid construction that combines precision and simplicity.

The

JX—1313

model is made to handle high production for versatile applications.

The

JX—1313

models come in two distinct sizes for the most common applications.

TECHNOLOGICAL ADVANTAGES * The most versatile cutting systems on the market today, covering the

full range of materials and thicknesses, even painted surfaces.

* Low cutting temperatures to prevent thermal alteration and residual tension.

* Clean cut without harmful atmospheres

* The cut surface neither cracks nor bends.

* Optimal utilization of raw material with negligible material loss

* Eliminates subsequent finishing processes.

* Ability to perform different types of cutting simultaneously

* Very strict tolerances..

* Low cutting temperatures to prevent thermal alteration and residual tension.

* Clean cut without harmful atmospheres

* The cut surface neither cracks nor bends.

* Optimal utilization of raw material with negligible material loss

* Eliminates subsequent finishing processes.

* Ability to perform different types of cutting simultaneously

* Very strict tolerances..

Product Paramenters

|

Parameter

|

Configuration

|

|

|

|

|

Assembly unit Name

|

Brand

|

|

|

Maximum pressure: 413Mpa(60000psi),

|

Motor

|

Beide of Siemens

|

|

|

Working pressure: 320~360Mpa

|

Axial Plunger pump

|

Hengyuan

|

|

|

Maximum flow rate: 3.8L/min

|

Hydraulic system

|

Sunny

Yuken |

|

|

Plunger pump power: 30kw

|

Inductive sensor

|

Contri-nex

|

|

|

Power supply: 380v 50HZ 3P

|

Hp Cylinder

|

BATA

|

|

|

Noise level: < 90db

|

Check tube assembly

|

HYPERTHERM

|

|

|

Motor rated power: 66A

|

Oil Cylinder

|

BATA

|

|

|

Size: 1620mmx1580mmx1360mm

|

HP seal kits

|

BATA

|

|

|

Weight: 1050kgs

|

Seals

|

America enterprise

|

|

|

Volume:3.48cub

|

Air cooling system

|

Chinese enterprise

|

|

|

|

1.Single-cylinder two-way reciprocating plunger intensifier

2.Single-row water drainage system 3.Manually pressure adjustment 4.Over pressure automatic shutdown protection |

|

|

Details Images

Control Cabinet

1. The capacity can continually supply abrasive for 500 to 800 minutes cutting(200-300kgs ).

2.New abrasive cup can convenient adjust abrasive flow.

1.Single-cylinder two-way reciprocating plunger intensifier

2.Single-row water drainage system

3.Manually pressure adjustment

4.Over pressure automatic shutdown protection

Working Table

1.Steel base of machine structure

2.Cantilever /Fly-arm made of Seamless cold-rolled manganese steel with 10mm thickness

3.No gap movement make sure machine move steady

2.Cantilever /Fly-arm made of Seamless cold-rolled manganese steel with 10mm thickness

3.No gap movement make sure machine move steady

4.Stainless steel dustcover protect drive system with long lift

5.Working table made by carbon steel with 5mm thickness

6.Working table apart from machine can keep cutting accuracy because no vibration effects

7.Automatic lubrication pump make drive system Real-time lubrication

5.Working table made by carbon steel with 5mm thickness

6.Working table apart from machine can keep cutting accuracy because no vibration effects

7.Automatic lubrication pump make drive system Real-time lubrication

Special design of non-adjustment make sure nozzle and orifice concentric .

Sand

Water jet cutting machine it is cut material by through high press sand .

Samples

metal cut

Stone cut

Aluminum cut

After service

Hot Searches