- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V-480V

-

Power:

-

30KW-90KW

-

Dimension(L*W*H):

-

10000*2000*2600mm

-

Weight (KG):

-

7000

-

Evaporation Capacity(kg/h):

-

300-1000

-

Product name:

-

Soybean Dryer

-

Keywords:

-

Drying Dryer Machine Biomass Dryer Machine

-

Raw material:

-

fruits, vegetables

-

Advantage:

-

Fully automatic, large output

-

Color:

-

custom made

-

Drying temperature:

-

70-90

-

Power supply:

-

220V-480V

-

After-sales service:

-

provide

-

Heating source:

-

Electricity, biomass pellets, coal, natural gas, steam

-

Installation:

-

support

Quick Details

-

Type:

-

Drying Oven

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KUNTENG

-

Voltage:

-

220V-480V

-

Power:

-

30KW-90KW

-

Dimension(L*W*H):

-

10000*2000*2600mm

-

Weight (KG):

-

7000

-

Evaporation Capacity(kg/h):

-

300-1000

-

Product name:

-

Soybean Dryer

-

Keywords:

-

Drying Dryer Machine Biomass Dryer Machine

-

Raw material:

-

fruits, vegetables

-

Advantage:

-

Fully automatic, large output

-

Color:

-

custom made

-

Drying temperature:

-

70-90

-

Power supply:

-

220V-480V

-

After-sales service:

-

provide

-

Heating source:

-

Electricity, biomass pellets, coal, natural gas, steam

-

Installation:

-

support

Production Description

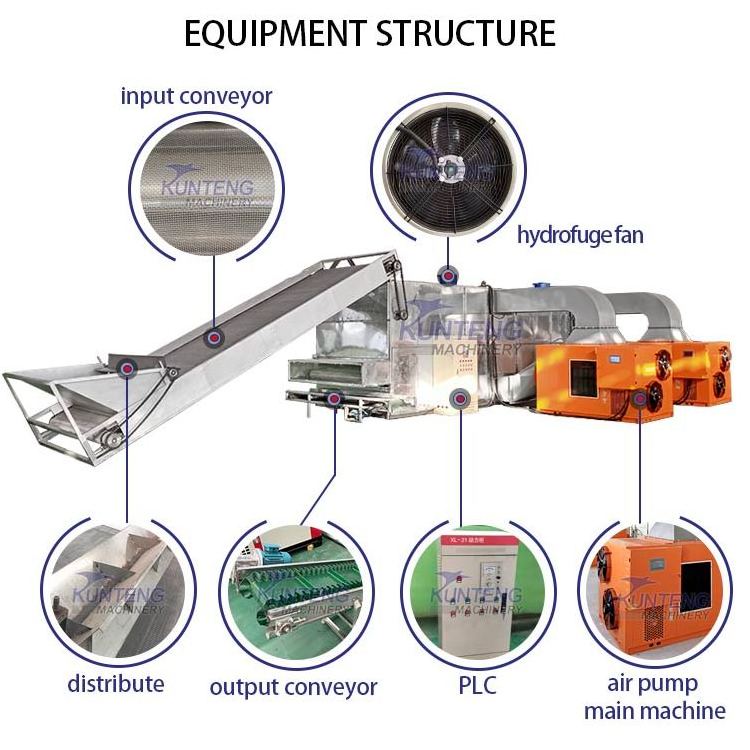

The mesh belt dryer is a kind of equipment that uses electric heating, steam heating, hot air heating, coal, natural gas and other heat sources to carry materials through the conveyor belt for drying.

Details display

The mesh belt dryer adopts continuous components, and the inside of the drying host has a multi-layer structure, which can be widely used in industry, food and other fields.

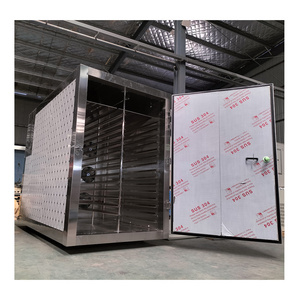

The oven is made of 304 stainless steel, which has the advantages of moisture resistance, corrosion resistance, and no rust.

Raw material

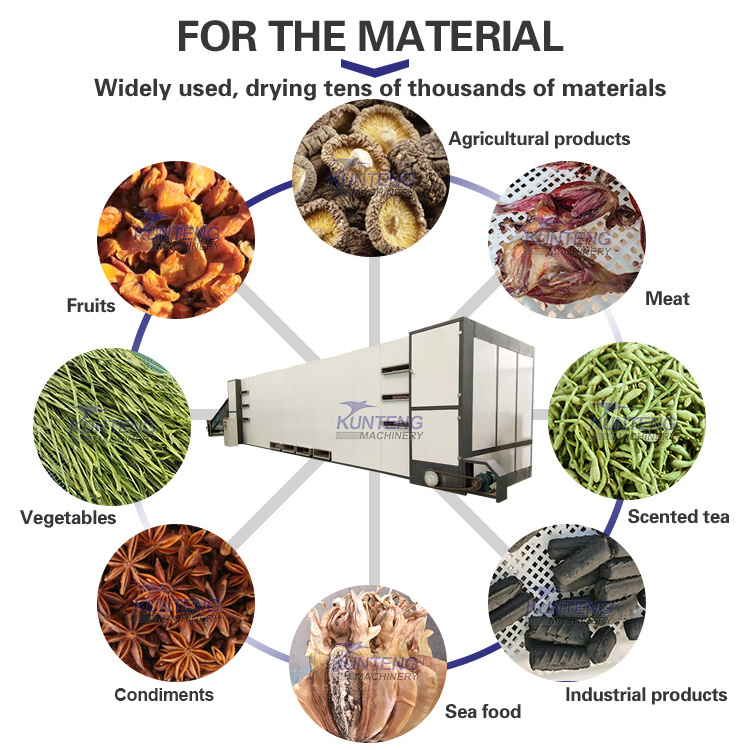

The mesh belt dryer mainly dries raw materials such as strips, flakes, granules, and blocks.

It is suitable for all kinds of fruits and vegetables, including beans, kidney beans, lentils, eggplants, red peppers, preserved fruit slices, fruit and vegetable slices, orange slices, etc.

It is a special equipment for dehydration and drying of fresh or seasonal vegetables and fruits.

Working principle

|

Model(Width*Length)

|

KT1.5-6-4

|

KT2-8-4

|

KT2-9-4

|

KT2-10-4

|

|||

|

Layers

|

4

|

|

|

|

|||

|

Drying area(㎡)

|

29

|

45

|

51

|

57

|

|||

|

Spread thickness of material(mm)

|

50-200

|

|

|

|

|||

|

Working temperature(℃)

|

0-120

|

|

|

|

|||

|

Working time(hour)

|

24

|

|

|

|

|||

|

Capacity(t/h)

|

100-150kg/h

|

200kg/h

|

250kg/h

|

300kg/h

|

|||

|

heat exchange furnace(M)

|

3.2*1*2.7

|

3.9*1.26*3

|

3.9*1.26*3

|

4.7*1.5*3

|

|||

|

Induced draft fan(kw)

|

11

|

15

|

15

|

22

|

|||

|

Exhaust fan(kw)

|

1.5

|

|

2.2

|

|

|||

|

Feeding conveyor(kw)

|

1.5

|

2.2

|

2.2

|

2.2

|

|||

|

Discharge conveyor(kw)

|

0.55

|

|

|

|

|||

|

Total power(kw)

|

14.55

|

19.25

|

19.95

|

26.95

|

|||

|

LP gas consumption

(90 degree fanrenheit)

|

20m³/H

|

25m³/H

|

28m³/H

|

30m³/H

|

|||

|

Place requirement

(W*L*H)M

|

4.5*14*2.7

|

5*19*2.8

|

4.5*20*2.8

|

5.5*21*2.8

|

|||

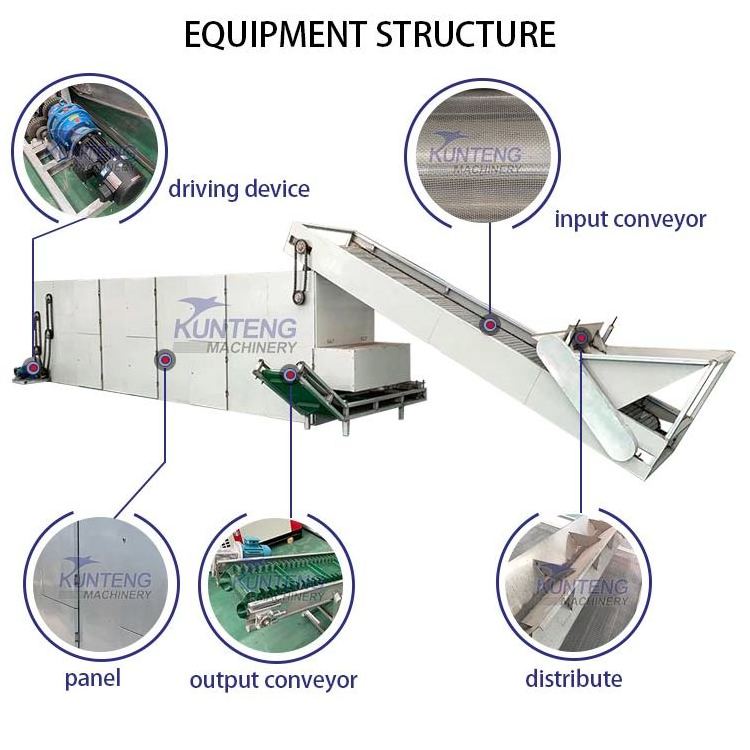

Vegetables and fruits are conveyed from the first layer to the last layer through the conveyor belt, and the dried vegetables and fruits pass through the discharge conveyor.

Hot air passes through the material from bottom to top, and the final moisture is discharged from the top of the dryer, which can be dried by heat or strong wind.

Therefore, drying efficiency and time can be improved. More convenient, fully automatic without manual loading and unloading.

Production Line

We can also design a complete fruit and vegetable drying production line. If the vegetable slicer, dryer, screening machine, vegetable cutter, dicing machine, bubble cleaning machine.

Fruit and vegetable related machines

Bubble Cleaner

When working, the bubble cleaner will release ozone to achieve the effect of cleaning and sterilizing. Widely used in family life and industrial and agricultural production.

Fruit and vegetable slicer

Power is transmitted to the blades through a transmission, causing them to spin at high speeds. When the vegetables are put into the feed port of the slicer, they are cut into thin slices by the blade and output from the discharge port.

Fruit and vegetable blanching machine

The blanching machine has the functions of fast greening, enzyme inhibition, color protection, dehydration and cooling, so that fruits and vegetables can maintain their original natural color

Fruit and vegetable dryer

The box-type drying room is suitable for dehydration and drying of various flakes, blocks, strips, dried fruits and vegetables.

Belt conveyors

Continuous belt movement is used to convey materials, and various materials are conveyed from one place to another.

Fruit and vegetable freeze dryer

The fruits and vegetables are pre-frozen into solid state at low temperature, and the solid ice in the fruits and vegetables is sublimated into a gaseous state and removed by the condenser to obtain freeze-dried fruit and vegetable products

CUSTOMER SITE

We have completed many design cases for customers all over the world.

It has rich industry experience and a database of hundreds of agricultural product drying processes.

According to the different needs of customers, we can customize production lines and supporting facilities at different prices.

Packing and shipping

COMPANY PROFILE

Henan Kunteng Machinery Manufacturing Co., Ltd. was established in 1999, mainly engaged in waste sorting equipment, charcoal equipment, drying equipment, and mineral processing equipment.

Such as baler, briquette machine, dryer, coal rod machine, charcoal machine, briquette machine and auxiliary equipment, comprehensive winnowing machine, etc.

The company has been approved as an independent import and export enterprise in China, an ISO international quality certification enterprise, and an EU CE certification enterprise.

It was rated as an honest private enterprise in Zhengzhou and a patent demonstration enterprise in Zhengzhou. Has obtained 8 utility model patents, 2 appearance patents, and applied for 1 invention patent.

FAQ

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer in China

Q2: How long is the warranty period?

A2: These garbage sorting equipment are usually guaranteed for 12 months. Wear parts are excluded.

Q3: What is your delivery time?

A3: We will arrange the machine to be shipped in the factory within 15 working days after receiving the advance payment.

We provide a complete production line, including factory design, circuit wiring, equipment placement, etc.

Hot Searches