- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ISOKING

-

Type:

-

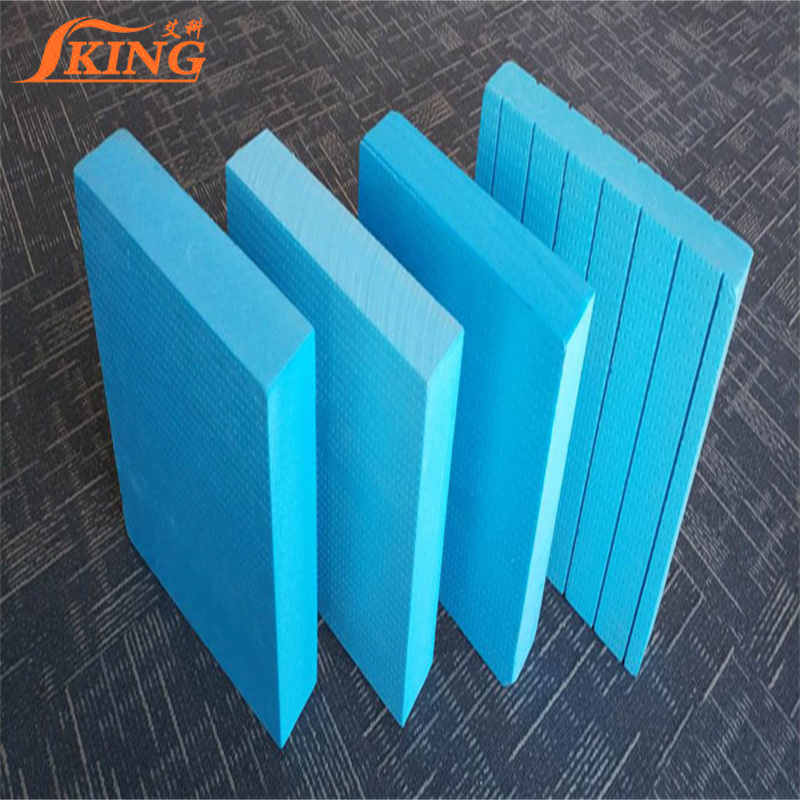

Foam Board Insulation

-

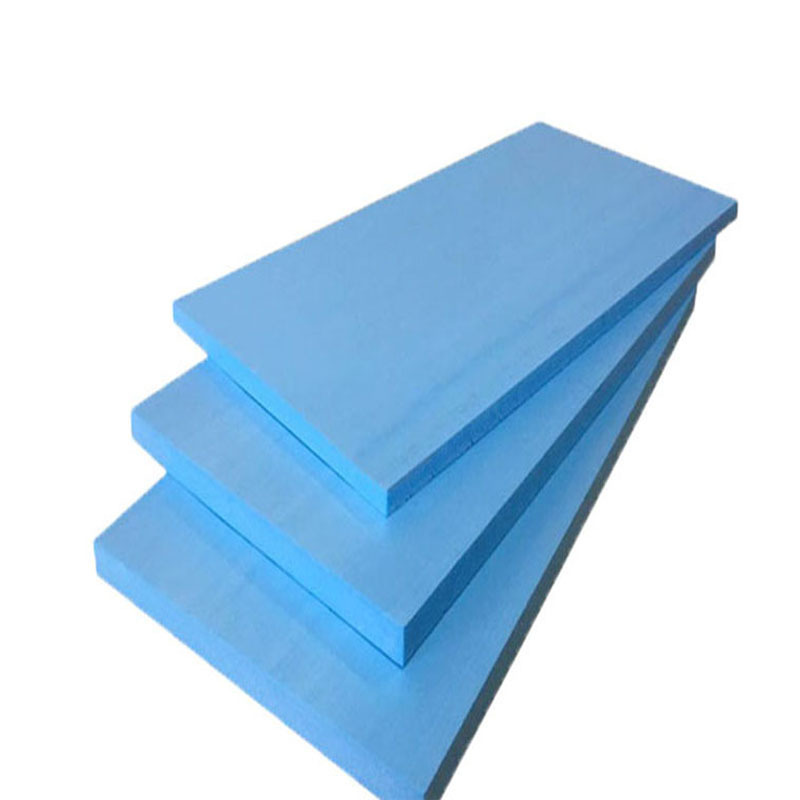

Color:

-

Red,, Green, Blue, White, Yellow

-

Size:

-

1.2mx0.6m; 2.4mx0.6m

-

Certificate:

-

ISO9001/CE/ISO14001

-

Advantage:

-

Energy-saving

-

Working Life:

-

40years

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ISOKING

-

Type:

-

Foam Board Insulation

-

Color:

-

Red,, Green, Blue, White, Yellow

-

Size:

-

1.2mx0.6m; 2.4mx0.6m

-

Certificate:

-

ISO9001/CE/ISO14001

-

Advantage:

-

Energy-saving

-

Working Life:

-

40years

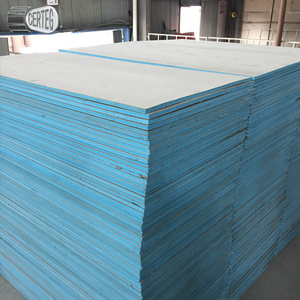

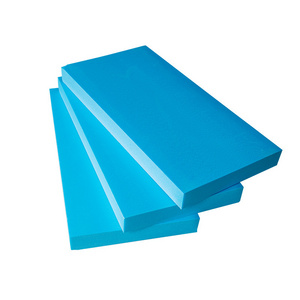

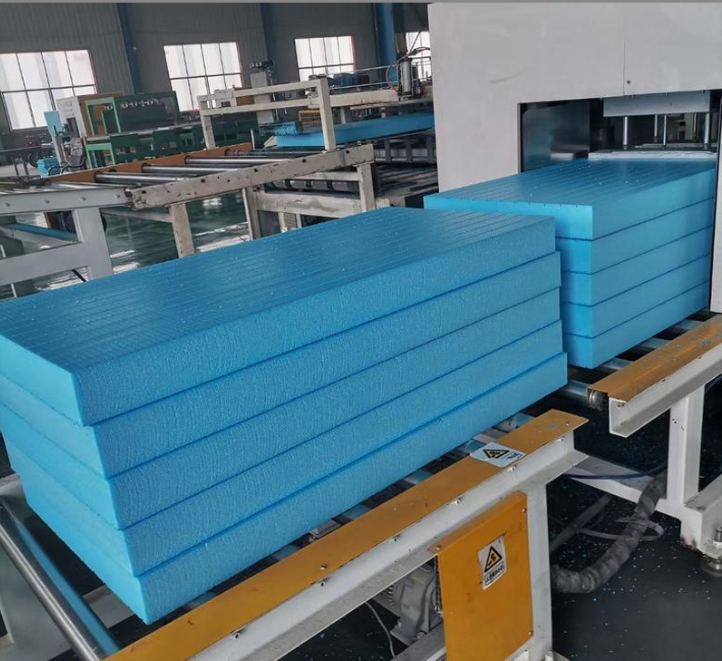

XPS foam board is a rigid foamed plastic board made of polystyrene resin as raw material plus other raw materials and polymers, mixed with heat and injected with a catalyst, and then extruded. Its scientific name is extruded polystyrene for heat insulation. Styrene foam plastic (XPS for short), XPS has a perfect closed-cell honeycomb structure, which makes the XPS board have extremely low water absorption (almost no water absorption), low thermal conductivity, high compression resistance, and aging resistance (normal Use almost no aging decomposition phenomenon).

|

Item |

Unit |

Size(mm) |

|

Length |

mm |

1800,1200 |

|

Width |

mm |

600, 900, 1200 |

|

Thickness |

mm |

20,25,30,40,50,60,70,80,90,100 |

|

Item |

Unit |

Performance |

Test Methods |

|

Compressive strength |

Kpa |

» 150 |

GB/ T 8813-1988 |

|

Water absorption rate soak in water for 96h |

%(W/W) |

<1.0 |

GB/T 8810-1988 |

|

Moisture permeability coefficient

|

ng/(m.s.pa) |

« 3.0 |

QB/T 2411-1998 |

|

Thermal Conductivity

|

W/(m.k) |

«0.028 «0.030 |

GB/T 10294-1988 |

|

Dimensional stability

|

% |

«1.5 |

GB/T 8811-1988 |

|

Oxygen Index |

|

»26 |

GB/T 8826-1988 |

1. Excellent thermal insulation

It has the characteristics of high thermal resistance, low linearity, and low expansion ratio. The closed cell rate of its structure has reached more than 99%, forming a vacuum layer, avoiding air flow and heat dissipation, and ensuring its long-lasting and stable thermal insulation performance. Compared with foamed polyurethane, it is 80% The closed cell rate is self-evident. Practice has proved that the 20mm thick XPS extruded insulation board has the same thermal insulation effect as 50mm thick expanded polystyrene and 120mm thick cement perlite. Therefore, this material is the best choice for building thermal insulation.

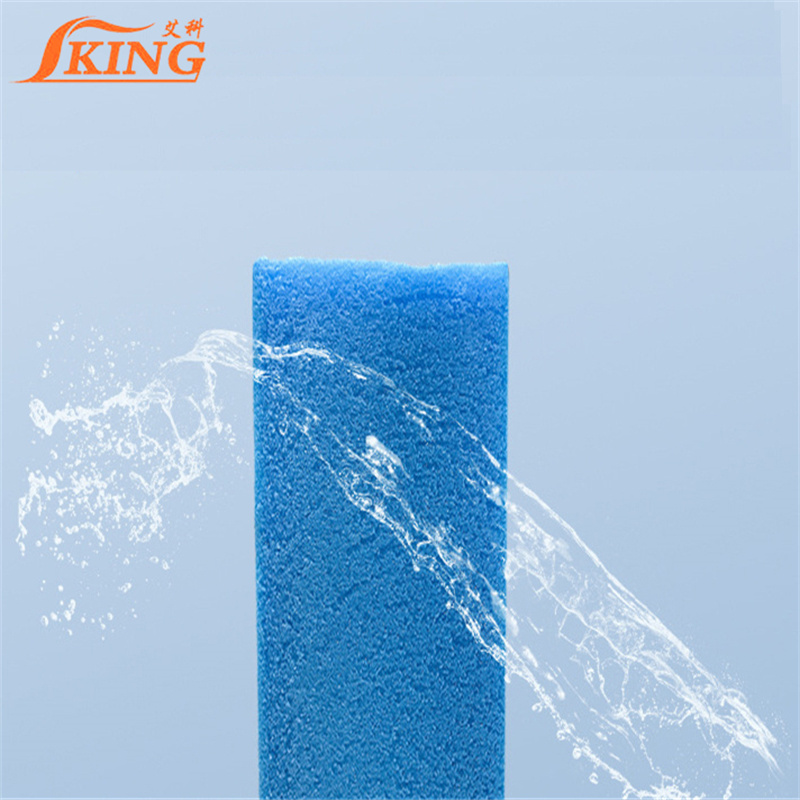

2. Excellent high-strength compression resistance

Due to the special structure of the XPS board, its compressive strength is extremely high and its impact resistance is extremely strong. According to different types and thicknesses of XPS, its compressive strength can reach more than 150-700Kpa, and it can bear the ground load of various systems. It is widely used in geothermal engineering, Highway, airport runway, square ground, large cold storage and car interior decoration and heat preservation and other fields.

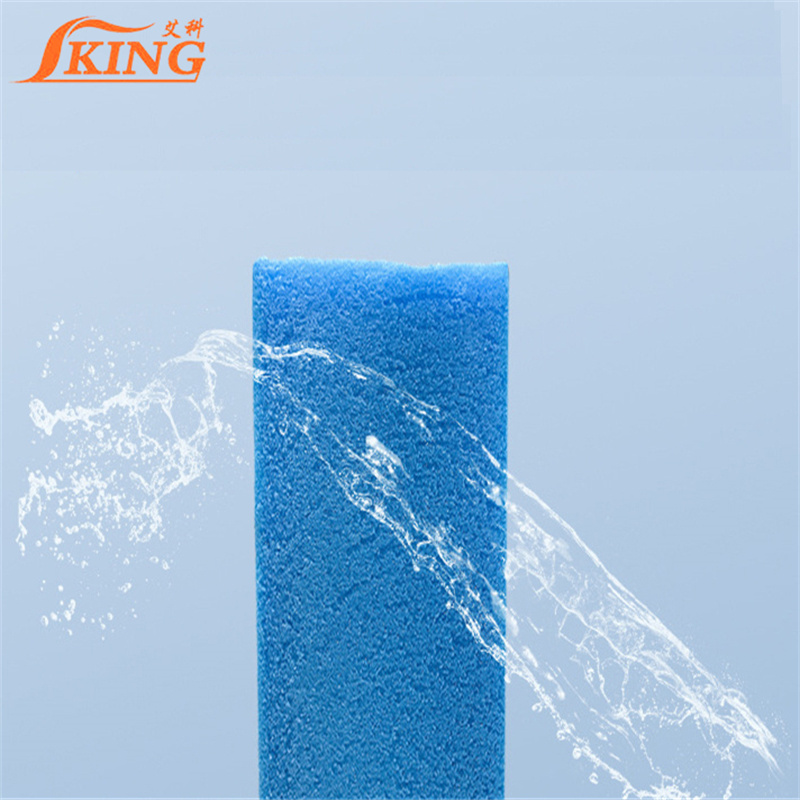

3.

Excellent water repellency and moisture resistance

Water absorption is an important parameter to measure insulation materials. After the thermal insulation material absorbs water, its thermal insulation performance decreases. Under low temperature conditions, the sucked water is easy to freeze, which destroys the structure of the thermal insulation material, thereby reducing the compression resistance and thermal insulation performance of the board. Since the molecular structure of polystyrene itself does not absorb water, the molecular structure of the board is stable and there are no gaps, which solves the problems of water leakage, penetration, frosting, and condensation of other materials.

4. Light texture, easy to use

The completely closed-cell foaming chemical structure and the honeycomb physical structure of the XPS board make it light and high-strength, easy to cut and transport, not easy to break, and easy to install.

5. Good stability and corrosion resistance

In long-term use, it will not age, decompose, or produce harmful substances. Its chemical properties are extremely stable. It will not be degraded by water absorption and corrosion, which will cause its performance to decline. It can still maintain its superior performance in high temperature environments. According to relevant information, the service life of XPS extruded plastic insulation board produced by major domestic manufacturers is about 60 years, and it can still maintain excellent performance, and it will not decompose or mildew, and there will be no volatilization of toxic substances.

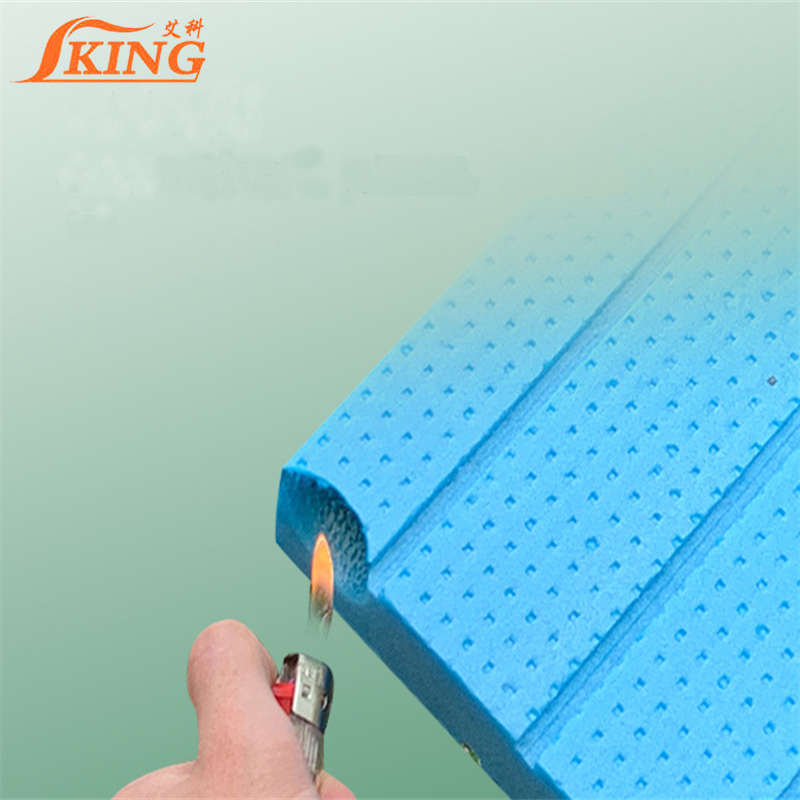

6. Product environmental performance

The environmental protection performance of XPS board mainly depends on the foaming agent. At present, most domestic manufacturers use CO2 as the catalyst, but some manufacturers have been using Freon. The relevant national departments have tested that the chemical performance is stable, does not volatilize harmful substances, and is harmless to the human body. The use of environmentally friendly materials does not produce any industrial pollution. This product is an environment-friendly building material.

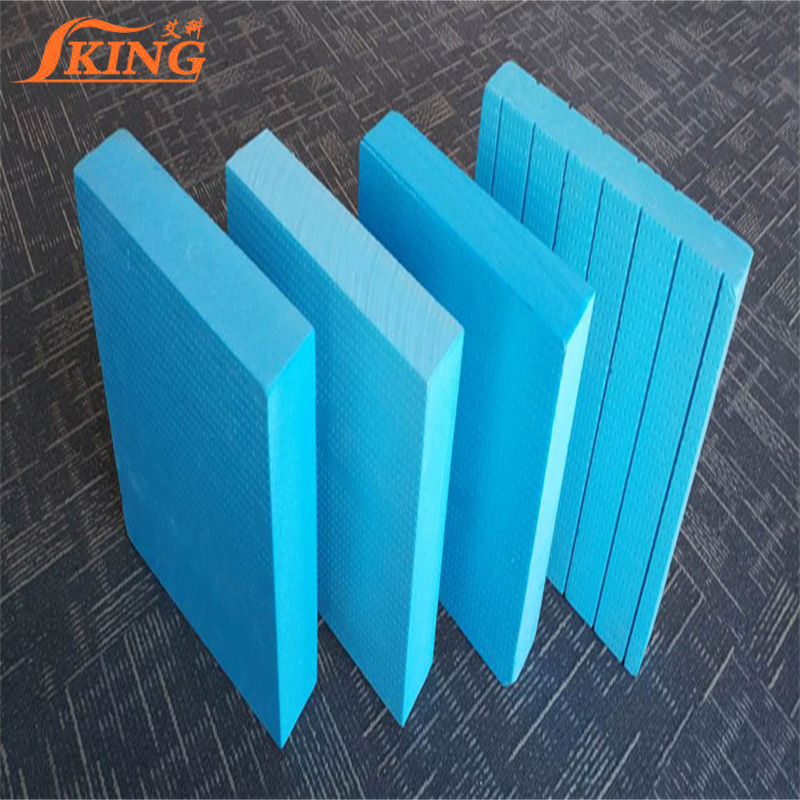

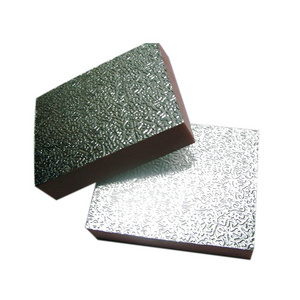

Surface treatment:

1.Smooth(with skin)

2.Line groove surface

3. Smooth(without skin)

4. Roughening(without skin)

Scope of application:

Building roof insulation, steel structure roof, building wall insulation, building ground moisturizing, square ground, ground frost heave control, central air conditioning ventilation ducts, etc.

IKING INTRODUCTION:

IKING GROUP established in 1995, a leading manufacturer and exporter of Glass Wool, Rock Wool , XPS foam Insulation in China. After more than 24 years' development, we totally have 6 producing lines for XPS Foam insulation.Now we have our own brand ISOKING. Our products are popular due to the high quality and competitive price all over the world.

KING VALUES: To be honesty trustworthy, thanksgiving dreams;

IKING RULES: Team work, Passionwork, share happines, embrace change.

IKING VISION: To be a trustworthy leadership enterprise of nsulation materials;

IKNG DUTY: To create value for IKING customers, to build plateform for IKING staff dreams;

"To win with quality and to be honest with reliable service" is the management theory we always adhere to. We also stick to the management strategy of "product creation, management creation and service creation". Based on the enterprise's principle of "to put persons on the top, to deal with people honestly".

Foreign exhibition show:

FAQ:

1. who are we?

We are based in Tianjin, China, start from 2014,sell to Southeast Asia(30.00%),South America(25.00%),Mid East(10.00%),South Asia(10.00%),Africa(5.00%),Eastern Asia(5.00%),Central America(5.00%),North America(3.00%),Oceania(2.00%),Western Europe(2.00%),Eastern Europe(00.00%),Northern Europe(00.00%),Southern Europe(00.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Glass Wool/Rock Wool/Rubber Foam/Ceramic Fiber/Aluminum Cladding

4. why should you buy from us not from other suppliers?

IKING Advantage: 1. 24 Hours services for oversea clients. 2. Fast feedback for inquiry within 3 Hours. 3. Fast delivery within 5 days after the order. 4. Strict QC to make Top quality for all roll 5. No.1 Production capacity in Asia. 10000tons/month

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,Arabic,French,Russian,Korean