- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

35-90%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

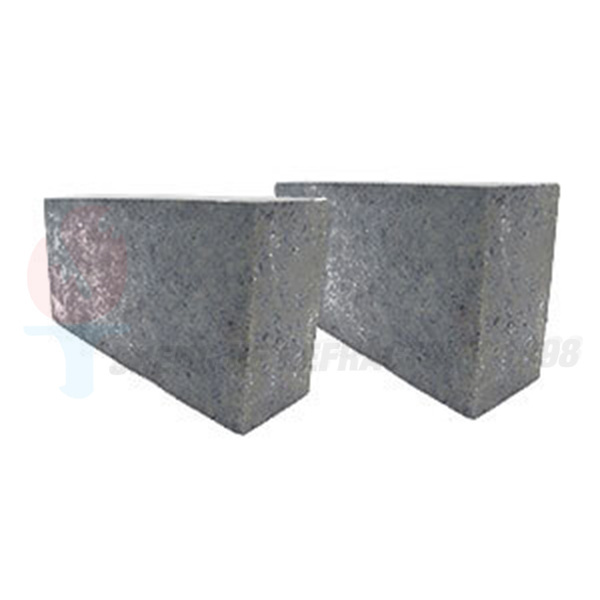

silicon carbide brick

-

Brand Name:

-

SHENGJIE

-

Bulk density g/cm3:

-

2.1-3.3g/cm3

-

Cold Crushing Strength:

-

60-120 Mpa

-

Certifiacte:

-

ISO9001

Quick Details

-

SiO2 Content (%):

-

10%

-

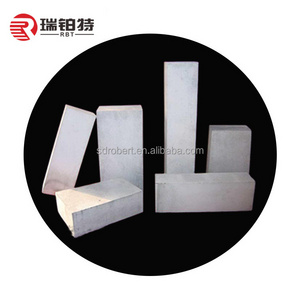

Al2O3 Content (%):

-

55-80%

-

MgO Content (%):

-

-

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

35-90%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

silicon carbide brick

-

Brand Name:

-

SHENGJIE

-

Bulk density g/cm3:

-

2.1-3.3g/cm3

-

Cold Crushing Strength:

-

60-120 Mpa

-

Certifiacte:

-

ISO9001

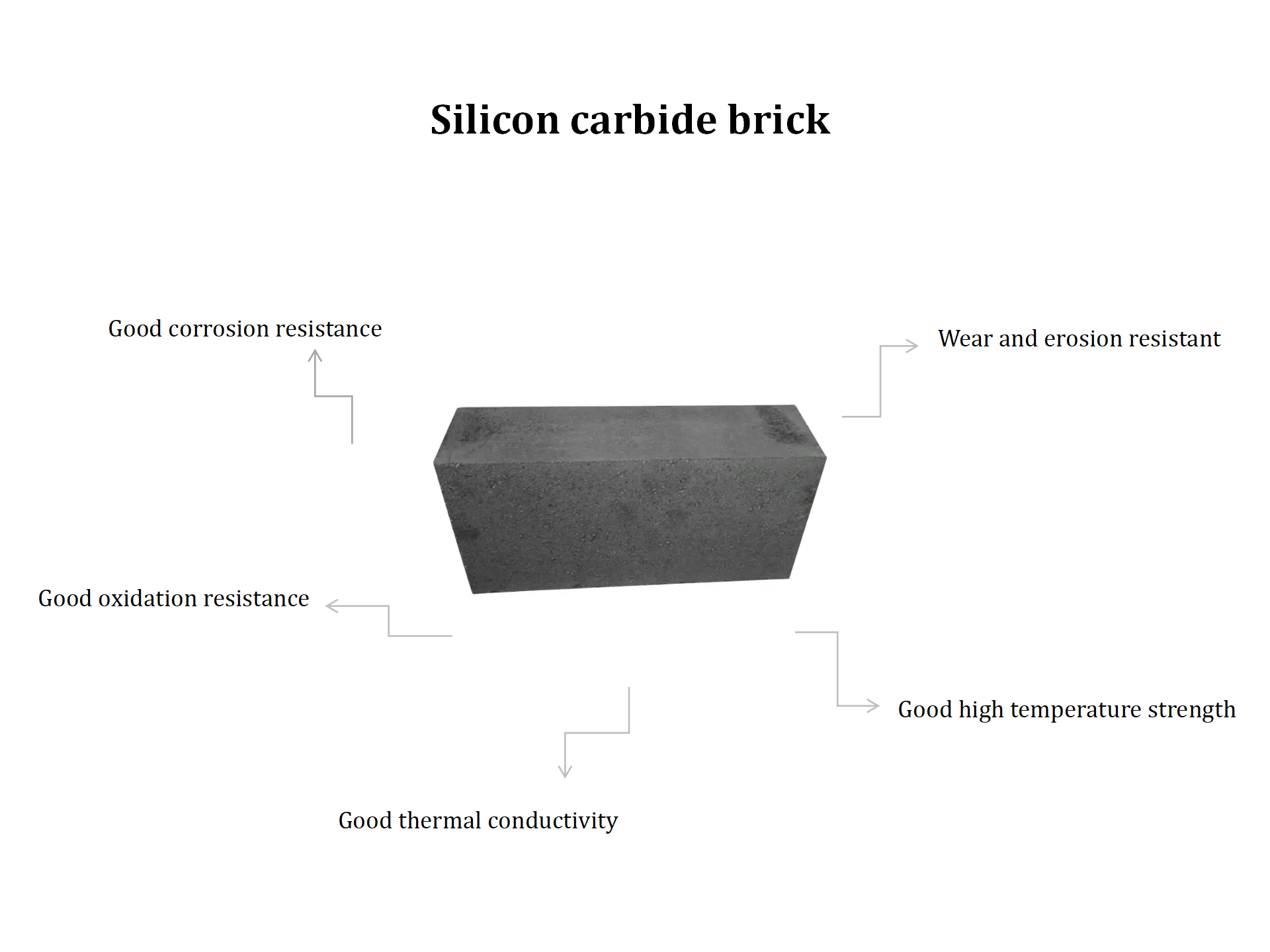

Product Description

Specification

|

Item

|

Silicon Carbide Brick

|

|

SiC %

|

≥70

|

|

Al₂O₃%

|

-

|

|

Bulk density g/cm

|

≥2.6

|

|

Apparent porosity %

|

≤22

|

|

Cold compressive strength MPa

|

≥100

|

|

Refractoriness under load

|

≥1700

|

|

ThermAl₂O₃ Conductivity

|

≥6

|

Application

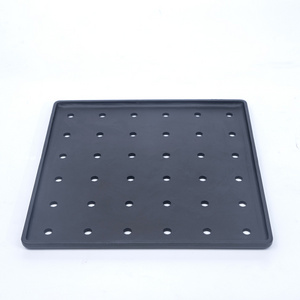

1.Non-ferrous metal smelting industry,ceramic,enamel and cement rotary kiln mouth, as well as glass annealing furnace and various kind of high temperature furnace.

2.Blast furnace lining,the lining of aluminium electrolytic bath,glass tank,structural ceramics,sanitary ceramics,domestic ceramics,electrotechnical porcelain refractory material, sinter powder metal industry.

3.Industrial ceramics bearing plate burning,pushing board, sagger; muff plate of annealing furnace;lining and ignitor of CFBB; lining of garbage incinerators,heat treatment electric heating furnace,soaking pit furnace etc.

4.Shed plates and flame insulation materials for silicate industrial kilns; Oil gas generator and organic waste combustion furnace in chemical industry;

2.Blast furnace lining,the lining of aluminium electrolytic bath,glass tank,structural ceramics,sanitary ceramics,domestic ceramics,electrotechnical porcelain refractory material, sinter powder metal industry.

3.Industrial ceramics bearing plate burning,pushing board, sagger; muff plate of annealing furnace;lining and ignitor of CFBB; lining of garbage incinerators,heat treatment electric heating furnace,soaking pit furnace etc.

4.Shed plates and flame insulation materials for silicate industrial kilns; Oil gas generator and organic waste combustion furnace in chemical industry;

Project cases

Hot Searches