- Product Details

- {{item.text}}

Quick Details

-

Working Pressure:

-

0.35Mpa

-

Separation particle size:

-

<4μm

-

Flow rate:

-

95-120L/min

-

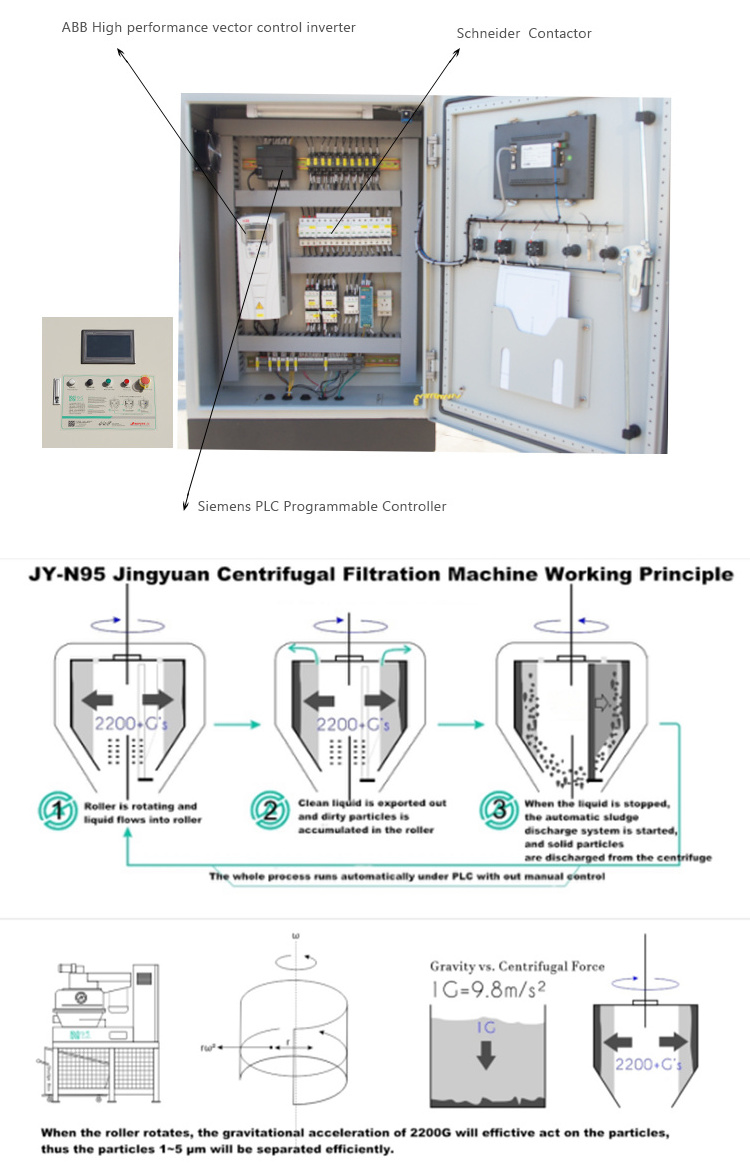

centrifugal force:

-

2200G

-

Separating Solid:

-

12kg/hour

-

PH:

-

Standard from 6 to 9

-

Rotor Speed:

-

2800 RPM to 3400 RPM

-

Operation:

-

PLC System

-

Certification:

-

CE ISO9001

Quick Details

-

Place of Origin:

-

China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts

-

Name:

-

Fully-automatic centrifuge Separator for Coolant Systems

-

Working Pressure:

-

0.35Mpa

-

Separation particle size:

-

<4μm

-

Flow rate:

-

95-120L/min

-

centrifugal force:

-

2200G

-

Separating Solid:

-

12kg/hour

-

PH:

-

Standard from 6 to 9

-

Rotor Speed:

-

2800 RPM to 3400 RPM

-

Operation:

-

PLC System

-

Certification:

-

CE ISO9001

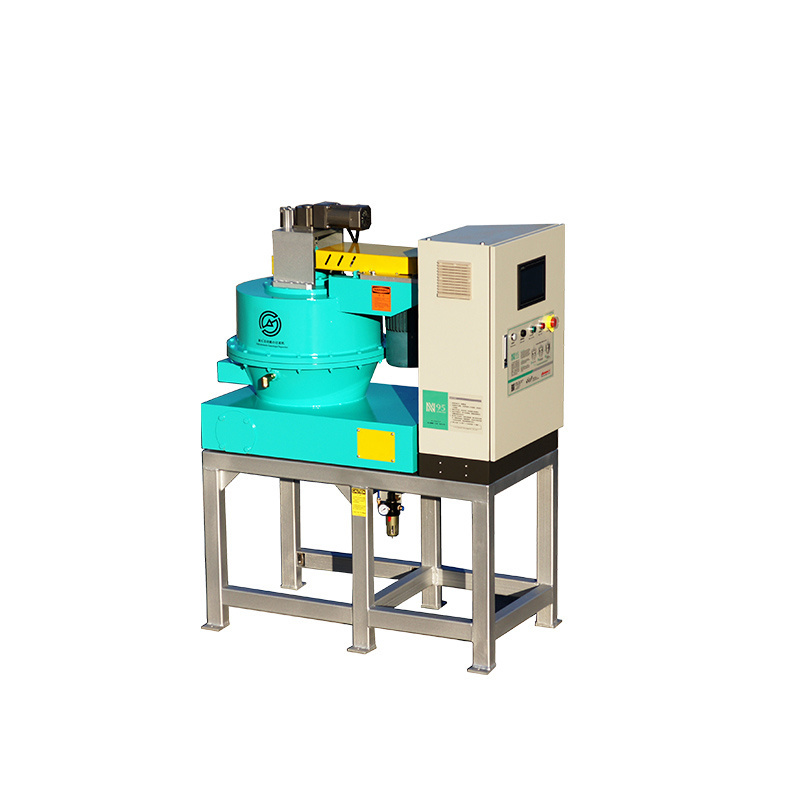

Fully-automatic centrifuge Separator for Coolant Systems

| Name | Automatic self-cleaning Centrifugal liquid-solid Separator |

| Model | JY-N95 |

| Brand Name | JINGYUAN |

| Place of Origin | Liaoning , China (Mainland) |

| Solid discharge | Automatic |

| Applicable Liquid | Any liquids (water or oil) with a specific gravity difference |

| Solid discharge | Automatic |

| Oil inlet | DN20 |

| Oil outlet | DN80 (3.0’) |

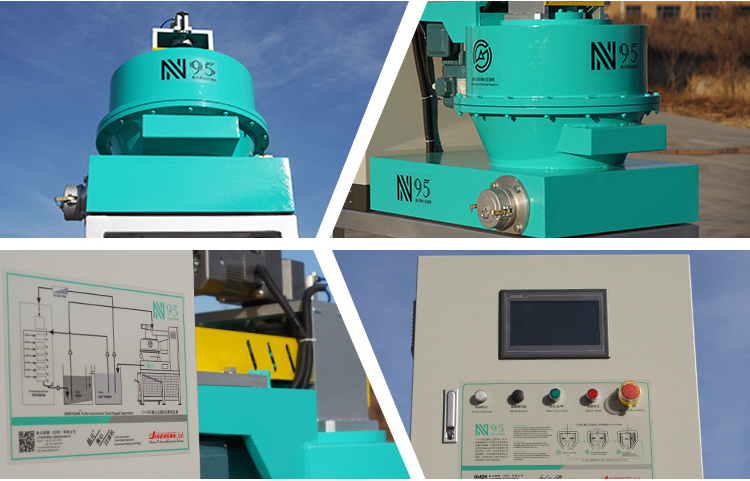

| Operation | PLC System |

| Rotor Speed | 2800 RPM to 3400 RPM |

| Voltage | 380V 3 Phase, 50Hz |

| PH | Standard from 6 to 9 |

| Separating Solid | 12kg/hour |

| Flow rate | 95-120L/min |

JY-N95 offers:

•Fully Automatic Operation without operator intervention.

•Self-cleaning ( Solids are discharged automatically through the bottom of the machine into a drum or collection bin ).

• Extract solid particulate regularly down to 0.5 ~1 micron.

• Uses no consumable media, such as bags, cartridges and filter paper.

• Maximized Tool and Fluid Life.

• Reduces waste disposal volume and associated costs.

• Extending the service life of process fluid and reducing abrasion and extending the service life of tools.

Usage:

The robust construction is ideally suited to the characteristics of abrasive solids such as glass, quartz,

ceramics, carbide, and metals. JY-N95 has proven results in the most demanding situations throughout a

wide range of industrial, commercial and institutional applications.

Glass grinding coolant filtration and recycling; paint booth water wash filtration; machine tool coolants;

Metal working fluid, wire drawing liquid, glass grinding liquid, metal working oil.

Cutting oil, cooling oil, circulating oil, lubricating oil anti-rust oil, hydraulic oil, forging oil, heat treatment oil,

drawing oil/stretching oil, gear oil, turbine oil, hot kerosene, quenching oil, compressor oil, transmission oil.

Hard disk processing sewage, glass processing sewage, ceramic processing sewage, screw processing

oil, vibratory grinding sewage, automobile painting sewage, cable processing oil, cutter processing sewage,

silicon wafer grinding sewage, grinding oil, bearing fine grinding oil, electric spark processing oil,

quenching oil, etc.

Copper drawing oil, aluminum drawing oil, screw forming oil, spark oil, stainless steel drawing oil,

quenching oil, screw and nut forming oil, oil pressure machine oil, heavy duty gear oil, high viscosity oil,

turbine oil, lubricating oil.

Screw nut forming machine, heat treatment oil, oil discharge machine, oil press, rolling machine oil,

other all kinds of industrial oil circulating oil, large ships double gear oil, hard machining processing

waste water, sewage, glass ceramic waste water, screw processing, vibration grinding oil sewage,

automobile coating waste water, cable oil, cutting tool machining grinding waste water, sewage and

silicon wafer grinding oil, bearing oil fine grinding, aqueous liquid, etc.

1.There are large amounts of scale and magnetic particles (iron oxide and iron powder) below 40 μ m contains in the emulsion of cold rolling plant. After centrifugal filtration, the yellow and black spots, as well as button-like impressions on the surface of strip steel and thin plate disappeared.

2.The emulsion used by wire and cable manufacturers is also available. After centrifugal filtration, the conductivity of the emulsion is controlled, and the "pinhole" on copper wire disappeared.