- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RLD

-

Model Number:

-

Custom Tricone Drill Bit

-

Size(inch/mm):

-

4~22INCH

-

Connection thread (API Reg):

-

(2 7/8)~(7 5/8)

-

Making up Torque (KN.m):

-

(6.1-7.5)~(46.1-54.2)

-

Weight(KG):

-

12~590

Quick Details

-

Weight (KG):

-

40

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RLD

-

Model Number:

-

Custom Tricone Drill Bit

-

Size(inch/mm):

-

4~22INCH

-

Connection thread (API Reg):

-

(2 7/8)~(7 5/8)

-

Making up Torque (KN.m):

-

(6.1-7.5)~(46.1-54.2)

-

Weight(KG):

-

12~590

Detailed Parameters

|

Size(inch/mm)

|

Connection thread

(API Reg)

|

Making up Torque (KN.m)

|

Weight(KG)

|

|

4 3/4 120.7

|

2 7/8

|

6.1-7.5

|

12

|

|

5 1/2 139.7

|

2 7/8

|

|

17

|

|

5 7/8 142.9

|

3 1/2

|

9.5-12.2

|

22

|

|

6 1/2 165.1

|

3 1/2

|

|

23

|

|

6 3/4 171.5

|

3 1/2

|

|

27

|

|

7 1/2 190.5

|

4 1/2

|

16.3-21.7

|

33

|

|

7 7/8 200

|

4 1/2

|

|

38

|

|

8 1/4 209.6

|

4 1/2

|

|

43

|

|

8 1/2 215.9

|

4 1/2

|

|

43

|

|

8 3/4 222.3

|

4 1/2

|

|

45

|

|

9 1/2 241.3

|

6 5/8

|

38-43.4

|

63

|

|

9 7/8 250.8

|

6 5/8

|

|

65

|

|

10 5/8 269.9

|

6 5/8

|

|

80

|

|

11 5/8 295.3

|

6 5/8

|

|

95

|

|

12 1/4 311.2

|

6 5/8

|

|

106

|

|

13 3/4 349.3

|

6 5/8

|

|

130

|

|

14 5/8 371.5

|

7 5/8

|

46.1-54.2

|

170

|

|

14 3/4 374.7

|

7 5/8

|

|

170

|

|

15 1/2 393.7

|

7 5/8

|

|

200

|

|

17 1/2 44.5

|

7 5/8

|

|

270

|

|

20 508

|

7 5/8

|

|

470

|

|

22 558.8

|

7 5/8

|

|

590

|

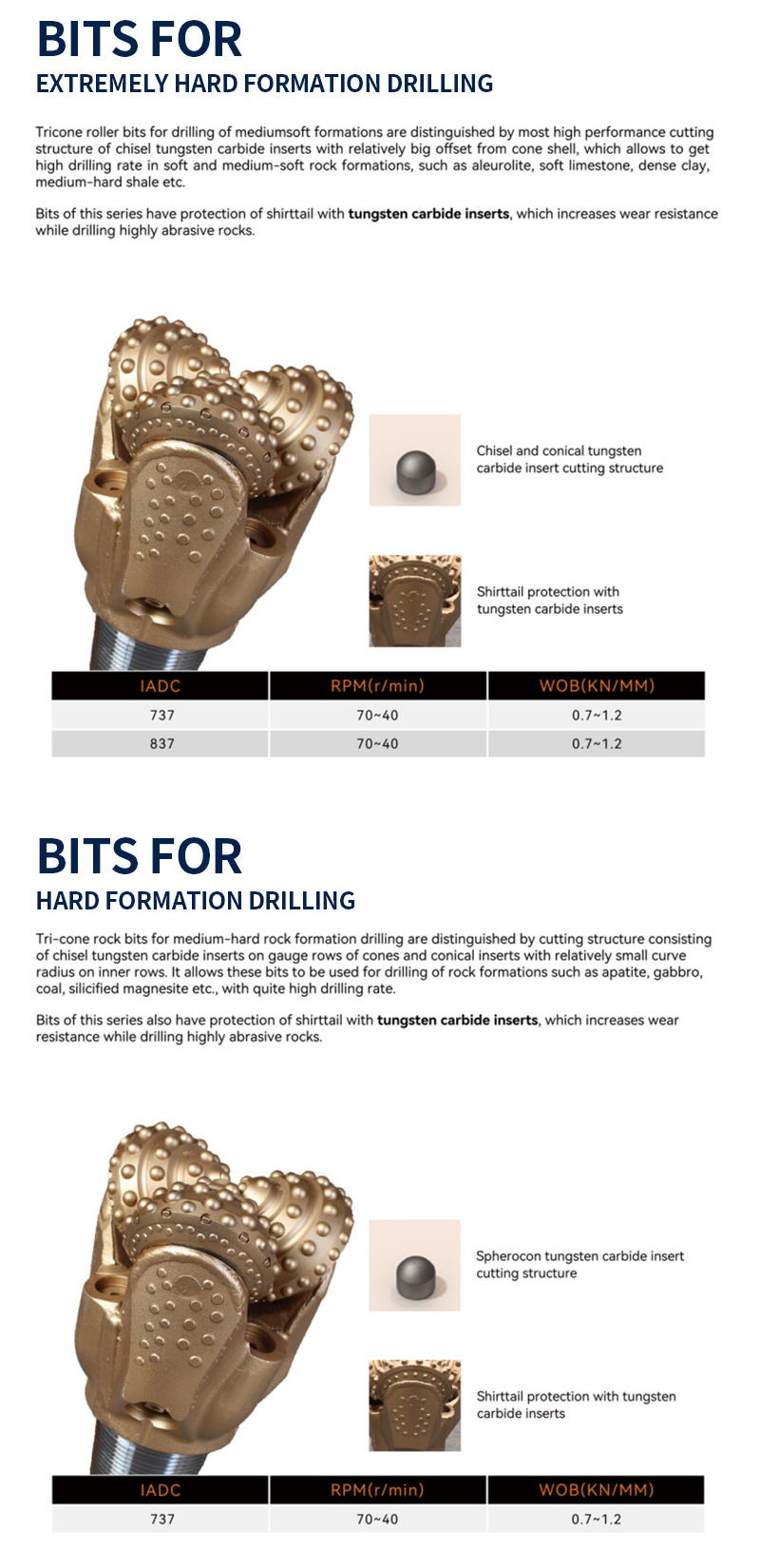

Tricone roller bits for dilling of mediumsoft formations are distinguished by most high performance cutting structure of chisel tungsten carbide inserts with relatively big offset from cone shell, which allows to get high drilling rate in soft and medium-soft rock formations, such as aleurolite, soft limestone, dense clay, medium-hard shale etc.

Bits of this series have protection of shirttail with

tungsten carbide inserts

, which increases wear resistance while drilling highly abrasive rocks.

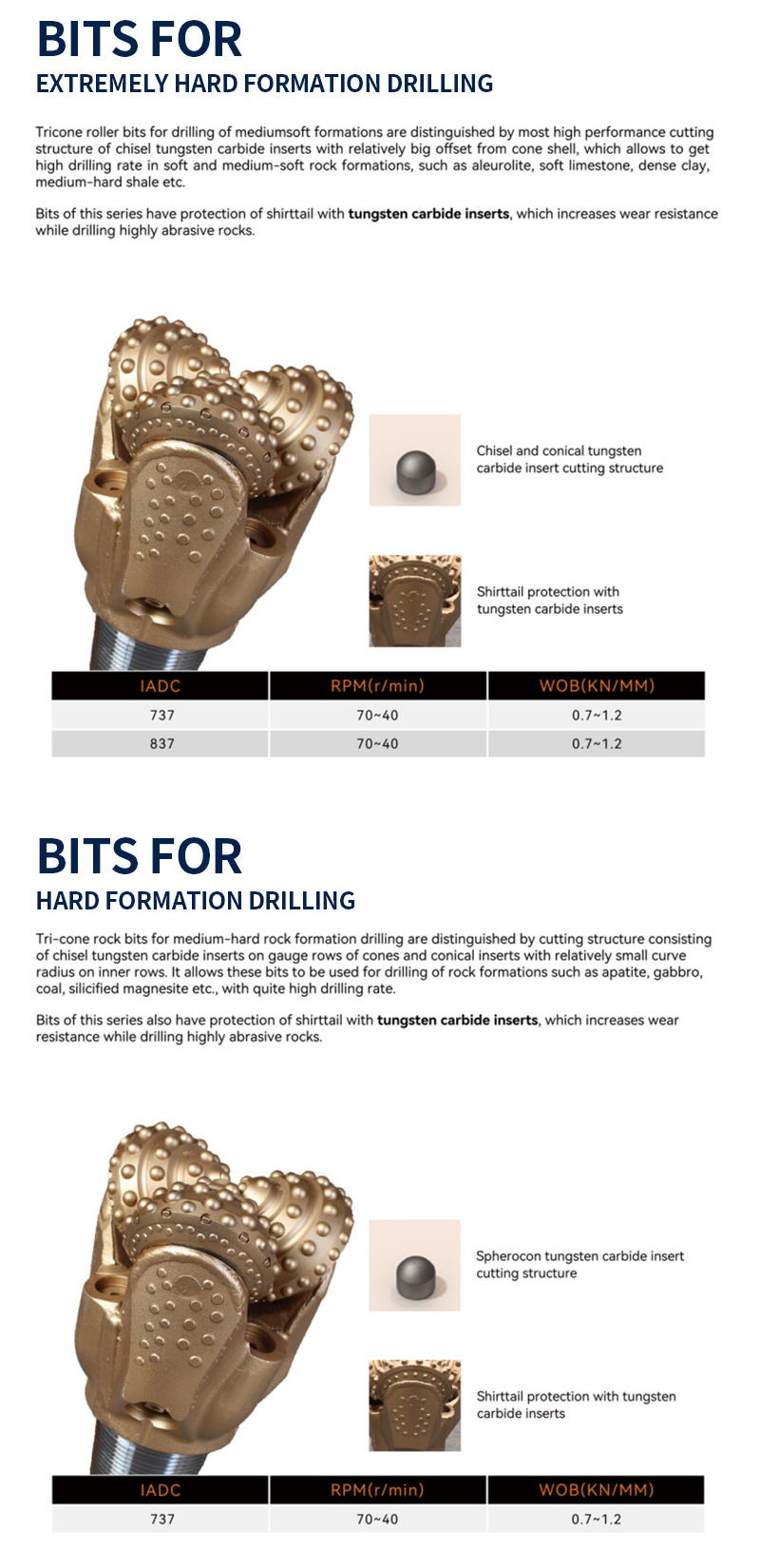

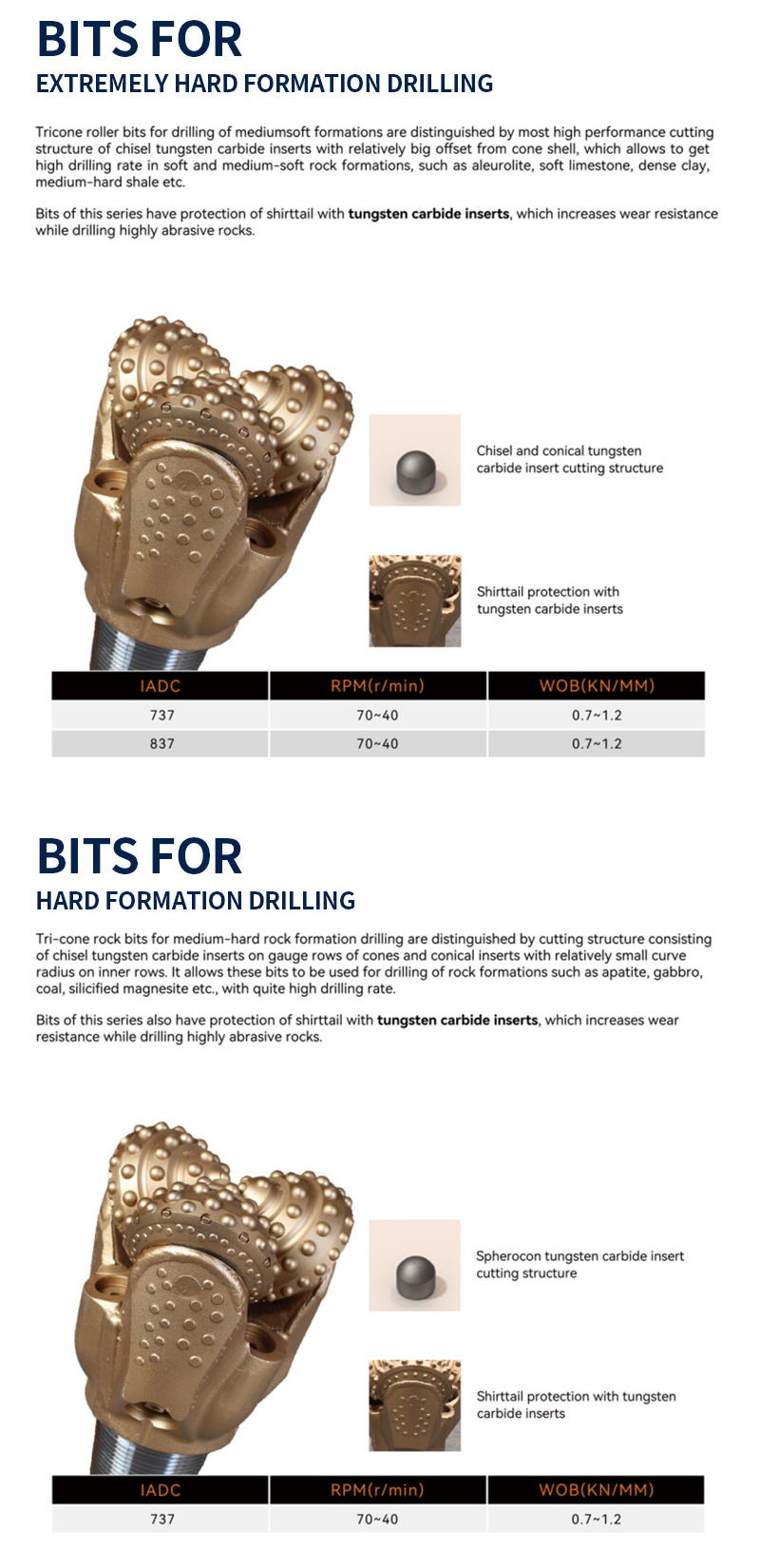

Tri-cone rock bits for medium-hard rock formation dilling are distinguished by cutting structure consisting of chisel tungsten carbide inserts on gauge rows of cones and conical inserts with relatively small curve radius on inner rows. It allows these bits to be used for drilling of rock formations such as apatite, gabbro, coal, silicified magnesite etc., with quite high drilling rate.

Bits of this series also have protection of shirttail with

tungsten carbide inserts

, which increases wear resistance while drilling highly abrasive rocks.

Tri-cone rock bits for medium-hard/hard rock formation dilling are distinguished by cutting structure fully consisting of conical tungsten carbide inserts with relatively small curve radius.Such cutting structure layout allows these bits to be used for driling of rock formations such as medium- and fine-grained basalt, finegrained granite, siliceous limestone, porphyry etc.

Bits of this series have protection of shirttail with

tungsten carbide inserts

, which increases wear resistance while drilling highly abrasive rocks.

Tri-cone rock bits for medium-hard rock formation dilling are distinguished by cutting structure consisting of chisel tungsten carbide inserts on gauge rows of cones and conical inserts with relatively small curve radius on inner rows. It allows these bits to be used for drilling of rock formations such as apatite, gabbro, coal, silicified magnesite etc, with quite high drilling rate.

Bits of this series also have protection of shittail with

tungsten carbide inserts

, which increases wear resistance while drilling highly abrasive rocks.

Tricone rller bits for dilling of mediumsoft formations are distinguished by most high performance cutting structure of chisel tungsten carbide inserts with relatively big offset from cone shell, which allows to get high drilling rate in soft and medium-soft rock formations, such as aleurolite, soft limestone, dense clay, medium-hard shale etc.

Bits of this series have protection of shirttail with

tungsten carbide inserts

, which increases wear resistance while drilling highly abrasive rocks.

Tri-cone rock bits for soft rock formation dilling and are thickened hardfacing on the surface and crest of cutters to improve wear resistance. It is suitable for surface hole dilling for every kind of well and upper section with good dillbilit, such as Limestone, Soft Shales, Soft Marble, Medium Shales, and so on.

Hot Searches