- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Greatcity

-

Voltage:

-

380V, 380V

-

Power:

-

4KW

-

Dimension(L*W*H):

-

1500*1600*1750mm

-

Weight:

-

3200

-

Product name:

-

thread rolling machine

-

Model:

-

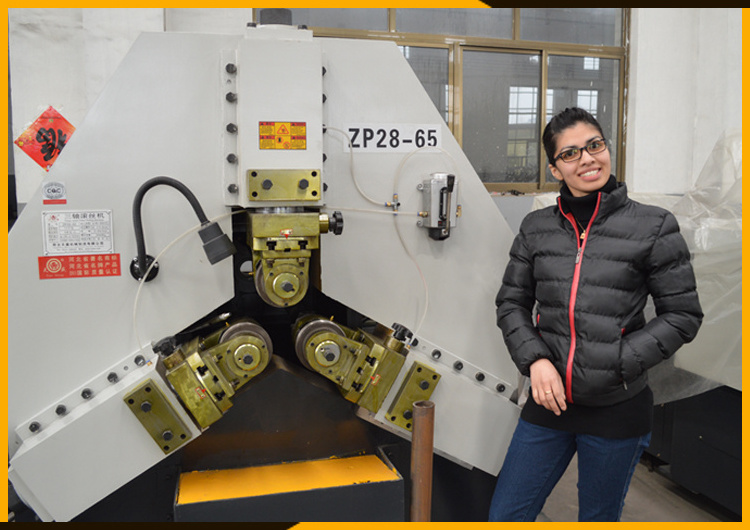

ZP28-65 thread rolling machine

-

Thread Pitch:

-

0.5-M8

-

Roller diameter:

-

125-160 mm

-

processing scope:

-

30-100 mm

-

Speed:

-

0-50 r / min

-

Roll pressure motor:

-

4 KW-4

Quick Details

-

Place of Origin:

-

Hebei, China

-

Application:

-

Rebar

-

Production Capacity:

-

100%

-

Brand Name:

-

Greatcity

-

Voltage:

-

380V, 380V

-

Power:

-

4KW

-

Dimension(L*W*H):

-

1500*1600*1750mm

-

Weight:

-

3200

-

Product name:

-

thread rolling machine

-

Model:

-

ZP28-65 thread rolling machine

-

Thread Pitch:

-

0.5-M8

-

Roller diameter:

-

125-160 mm

-

processing scope:

-

30-100 mm

-

Speed:

-

0-50 r / min

-

Roll pressure motor:

-

4 KW-4

Product introduction

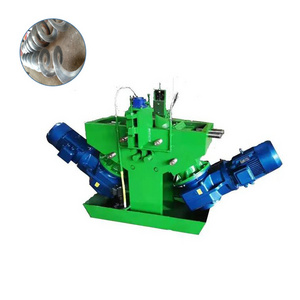

Screw Conveyor Making Machine Screw Flight Making Machine Screw Forming Cold Thread Rolling Machine

Outline of Thread Forming Machine :

Thread Forming Machine is a multi-function cold extrusion machine. The machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. The machine has a safe and reliable electro-hydraulic execution and control system.

Each work cycle can be selected in manual, semi-automatic and automatic ways.

Thread Forming Machine is an advanced non-cutting processing, can effectively improve the internal and surface quality of the workpiece.

When processed, the radial compression stress generated, can significantly improve the fatigue strength of the workpiece and the reverse strength. It is an efficient, energy saving, low consumption of the ideal process.

Thread Forming Machine is a multi-function cold extrusion machine. The machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. The machine has a safe and reliable electro-hydraulic execution and control system.

Each work cycle can be selected in manual, semi-automatic and automatic ways.

Thread Forming Machine is an advanced non-cutting processing, can effectively improve the internal and surface quality of the workpiece.

When processed, the radial compression stress generated, can significantly improve the fatigue strength of the workpiece and the reverse strength. It is an efficient, energy saving, low consumption of the ideal process.

Products Description

Technical parameter

|

Product Name

|

pipe threading machine

|

|

Model

|

ZP28-65

|

|

Rolling Motor

|

11 KW

|

|

Roll pressure motor

|

4KW-4

|

|

Roller diameter

|

Φ125-Φ160 mm

|

|

processing scope

|

Φ30-100 mm

|

|

rolling pitch

|

0.5-M8

|

|

Speed

|

0-50 r / min

|

|

Weight

|

3200 kg

|

|

Dimensions

|

1500 * 1600 * 1750 mm

|

Hot Searches