- Product Details

- {{item.text}}

Quick Details

-

Control Software:

-

Golden Laser Software

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Golden Laser

-

Weight (KG):

-

3000 KG

-

Applicable Industries:

-

Clothing Industry, Home Textiles, Industrial, Automotive, Aerospace, Outdoors, Medical Industry, Protective Equipment, Sport Industry, etc

-

Products handled:

-

Roll Fed

-

Power supply:

-

AC220V±5% 50/60Hz

Quick Details

-

Laser Type:

-

CO2

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

2300mm*2300mm

-

Control Software:

-

Golden Laser Software

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Golden Laser

-

Weight (KG):

-

3000 KG

-

Applicable Industries:

-

Clothing Industry, Home Textiles, Industrial, Automotive, Aerospace, Outdoors, Medical Industry, Protective Equipment, Sport Industry, etc

-

Products handled:

-

Roll Fed

-

Power supply:

-

AC220V±5% 50/60Hz

Product Description

Textile Laser Cutting Solution

__

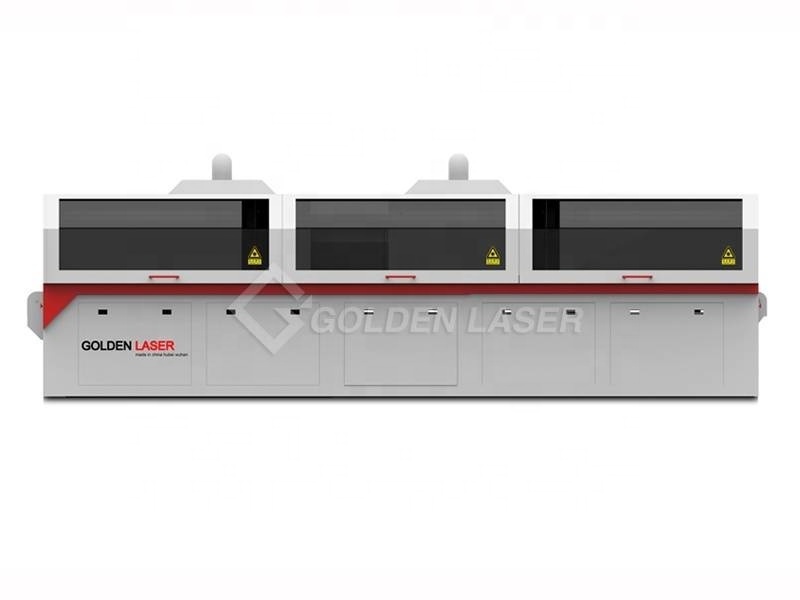

GoldenLaser - JYCCJG-230230LD

is a h

igh performance CO2 laser cutting system for industrial fabrics. It is high stability, high efficiency and highly automated. This laser cutter machine is ideally suitable for cutting a variety of soft materials including fabrics, gaskets, thermal insulation fabrics, and technical textiles for a wide range of applications from the filtration industry to the automotive and military industries.

Now it’s time for you to consider using laser solutions and giving your company an edge over the competition.

Specification

|

JYCCJG-230230LD

Technical Parameters

|

|

|

|

Laser type

|

CO2 laser

|

|

|

Laser power

|

150w, 300w, 600w, 800w

|

|

|

Working area (W × L)

|

2300mm×2300mm (90.5”×90.5”)

|

|

|

Max. material width

|

2300mm (90.5”)

|

|

|

Working table

|

Vacuum conveyor working table

|

|

|

Cutting speed

|

0 ~ 1200mm/s

|

|

|

Acceleration

|

8000mm/s2

|

|

|

Repositioning accuracy

|

≤0.05mm

|

|

|

Motion system

|

Servo motor, Gear and rack driven

|

|

|

Power supply

|

AC220V±5% 50/60Hz

|

|

|

Graphics format supported

|

PLT, DXF, AI, DST, BMP

|

|

|

※

Working areas can be customized as per requirement.

|

|

|

Benefits

__

* Textiles can be laser cut with a method that thermally seals the edges and eliminates fraying.

* Laser cutters have the ability to cut fabric without pressure, therefore lessens the possibility of its shape being distorted.

* Laser cutting works get done at a tremendous precision and consistent high quality.

* Laser cutting, engraving and perforation possible in one operation.

* Laser cutters have the ability to cut fabric without pressure, therefore lessens the possibility of its shape being distorted.

* Laser cutting works get done at a tremendous precision and consistent high quality.

* Laser cutting, engraving and perforation possible in one operation.

Capable of cutting composite material

Creation of designs on delicate fabrics

Laser cutting smoothly, no burnt edges

Highlights

__

1. Gear & Rack driven:

High-precision Gear & Rack driving system. High speed cutting. Speed up to 1200mm/s, acceleration 8000mm/s2, and can maintain long-term stability.

2. Precision tension feeding:

No tension feeder will easy to distort the variant in the feeding process, resulting the ordinary correction function multiplier. Tension feeder in a comprehensive fixed on both sides of the material at the same time, with automatically pull the cloth delivery by roller, all process with tension, it will be perfect correction and feeding precision.

3. Automatic sorting system:

* Increase the processing quality. Automated unloading of the completed cut parts.

* Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

* Increase the processing quality. Automated unloading of the completed cut parts.

* Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

4. Working areas can be customized:

2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4 in)

2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4 in)

Options

__

* Honeycomb Conveyor System

makes continuous processing of your products.

* Auto Feeder can hold the roll flexible materials and continually deliver materials into the laser cutter machine.

* Marking Systems (Ink Jet Printer Module) can draws graphics and labels on your material.

* CCD Camera: Automatic camera detection enables printed materials to be cut out precisely along the printed outline.

* Galvanometer Scanners can be used for laser engraving and perforation with unmatched flexibility, speed and accuracy

* Red Dot Positioning can check whether your roll material on both sides is aligned.

* Auto Feeder can hold the roll flexible materials and continually deliver materials into the laser cutter machine.

* Marking Systems (Ink Jet Printer Module) can draws graphics and labels on your material.

* CCD Camera: Automatic camera detection enables printed materials to be cut out precisely along the printed outline.

* Galvanometer Scanners can be used for laser engraving and perforation with unmatched flexibility, speed and accuracy

* Red Dot Positioning can check whether your roll material on both sides is aligned.

Applications

Applicable Materials

Polyester (PES), viscose, cotton, nylon, nonwoven and woven fabrics, synthetic fibers, polypropylene (PP), knitted fabrics, felts, polyamide (PA), glass fiber (or glass fibre, fiberglass, fibreglass), Lycra, mesh, Kevlar, aramid, polyester PET, PTFE, paper, foam, cotton, plastic, etc.

Applications

1. Clothing Textiles: technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, curtains, cushion materials, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, etc.

4. Textiles used in automotive and aerospace: aircraft carpets, cat mats, seat covers, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes, paragliding, kitesurf, boats (inflatable), air balloons, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.

Polyester (PES), viscose, cotton, nylon, nonwoven and woven fabrics, synthetic fibers, polypropylene (PP), knitted fabrics, felts, polyamide (PA), glass fiber (or glass fibre, fiberglass, fibreglass), Lycra, mesh, Kevlar, aramid, polyester PET, PTFE, paper, foam, cotton, plastic, etc.

Applications

1. Clothing Textiles: technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, curtains, cushion materials, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, etc.

4. Textiles used in automotive and aerospace: aircraft carpets, cat mats, seat covers, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes, paragliding, kitesurf, boats (inflatable), air balloons, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.

Packing & Delivery

Hot Searches