- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

739*322mm

-

Heat Exchanged:

-

150-450KW

-

Certifications:

-

CE/ISO9001/ISO14001

-

Plate material:

-

Stainless steel(316L,304)

-

Solder material:

-

Copper

-

Marketing Type:

-

New Product 2021, New Product 2021

-

Core Components:

-

Heat Exchanger, Heat Exchanger

-

Liquid Flow Rate:

-

105m3/h

Quick Details

-

Place of Origin:

-

Zhejiang, China, Zhejiang, China

-

Brand Name:

-

Forwon, Forwon

-

Maximum Working Pressure:

-

6.75MPa

-

Voltage:

-

220V

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

739*322mm

-

Heat Exchanged:

-

150-450KW

-

Certifications:

-

CE/ISO9001/ISO14001

-

Plate material:

-

Stainless steel(316L,304)

-

Solder material:

-

Copper

-

Marketing Type:

-

New Product 2021, New Product 2021

-

Core Components:

-

Heat Exchanger, Heat Exchanger

-

Liquid Flow Rate:

-

105m3/h

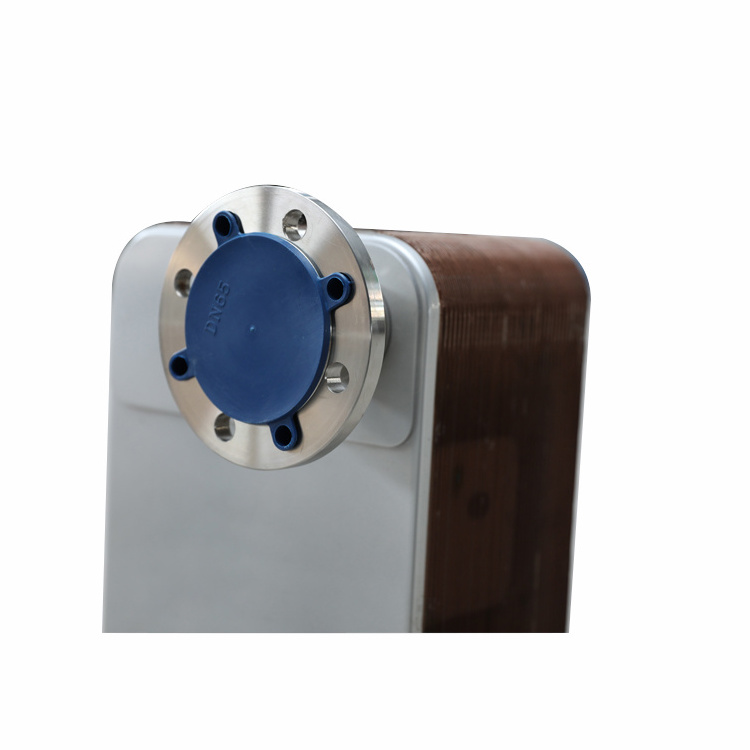

FHC210 ac250eq air conditioning gasket heat pump plate heat exchanger

1.Compact structure: adopt thin stainless steel, high heat transfer factors.

2.Reliability: adopt 316L and copper as well as high quality brazing works. Endure high pressure and temperature. Long life and no

maintenance need.

3.Reduce water require: with the high heat transfer efficiency, only needs 1/3 water usage compare to shell and tube exchanger

under same condition

4.Lightly: Only 20-30% weight compare to shell and tube heat exchanger and reduce the logistics cost.

5.Low fouling factors: high disorderly flow lower the fouling condition, reduce the maintain.

6.With distributor: increase the refrigerant evaporating efficiency and reduce the risks by using distributor to force the

refrigerant flow direction.

2.Reliability: adopt 316L and copper as well as high quality brazing works. Endure high pressure and temperature. Long life and no

maintenance need.

3.Reduce water require: with the high heat transfer efficiency, only needs 1/3 water usage compare to shell and tube exchanger

under same condition

4.Lightly: Only 20-30% weight compare to shell and tube heat exchanger and reduce the logistics cost.

5.Low fouling factors: high disorderly flow lower the fouling condition, reduce the maintain.

6.With distributor: increase the refrigerant evaporating efficiency and reduce the risks by using distributor to force the

refrigerant flow direction.

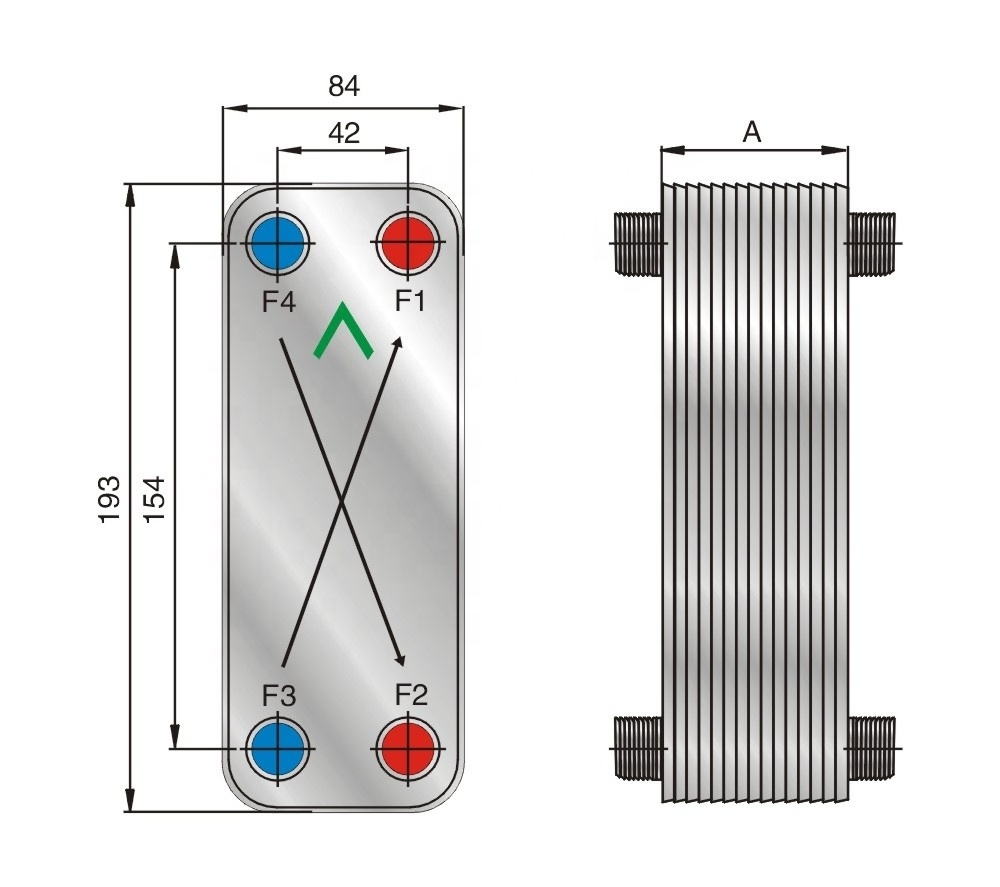

|

Heat load up

|

150~450 KW

|

|

Size

|

739*322 mm

|

|

Thickness of plate

|

0.4mm

|

|

Heat exchanger area of each plate

|

0.210

|

|

Volume

|

0.400L/Channel

|

|

Quantity of max plates

|

250

|

|

Design pressure

|

3.0/4.5MPa

|

|

Testing pressure

|

4.5/6.7MPa

|

|

Design temperature

|

- 196~ +200

|

|

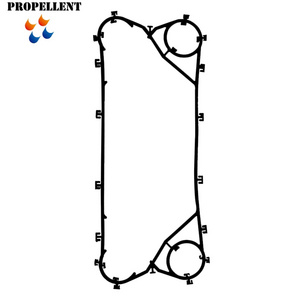

Model of flow course plate

|

H & HQ & HDQ

|

|

The max size of connector

|

4

|

Details Images

Hot Searches