- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

LUM

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

1350*1500*1600

-

Weight:

-

4500 kg

-

Marketing Type:

-

New Product 2022

-

PLC Brand:

-

OTHER

-

Name:

-

corrugated cardboard creasing and cutting machine

-

Plane Working Area:

-

1300*920MM

-

Creasing and Cutting Speed:

-

25±3 Stride/min

-

Main Engine POW:

-

2.2KW

-

Net Weight of Machine:

-

2000KG

-

Overall Dimensions:

-

1350*1500*1600MM

-

Feeding Mode:

-

Hand Feeding

-

CUSTOM:

-

YES

-

COLOR:

-

BLUE,BLACK OR CUSTOM

-

Creasing and Cutting Knife Line Area:

-

<15M

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

150 m/min

-

Max. workable width:

-

1400mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

LUM

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

1350*1500*1600

-

Weight:

-

4500 kg

-

Marketing Type:

-

New Product 2022

-

PLC Brand:

-

OTHER

-

Name:

-

corrugated cardboard creasing and cutting machine

-

Plane Working Area:

-

1300*920MM

-

Creasing and Cutting Speed:

-

25±3 Stride/min

-

Main Engine POW:

-

2.2KW

-

Net Weight of Machine:

-

2000KG

-

Overall Dimensions:

-

1350*1500*1600MM

-

Feeding Mode:

-

Hand Feeding

-

CUSTOM:

-

YES

-

COLOR:

-

BLUE,BLACK OR CUSTOM

-

Creasing and Cutting Knife Line Area:

-

<15M

China suppliers corrugated cardboard creasing and cutting machine

Main model for corrugated cardboard creasing and cutting machine:

|

Model |

Max Working Area |

Working speed |

Creasing length |

Motor Power |

Weight |

Overall Size (L×W×H) |

|

PYQ401C |

750×520mm |

28±2 (strokes/min) |

<15m |

2.2kw |

2000kg |

1260×1350×1280mm |

|

PYQ203D |

930×670mm |

23±2 (strokes/min) |

<25m |

4.0kw |

3000kg |

1800×1600×1600mm |

|

ML1100 |

1100×800mm |

20±2 (strokes/min) |

<32m |

5.5kw |

4500kg |

1900×1800×1700mm |

|

ML1200 |

1200×830mm |

20±2 (strokes/min) |

<35m |

5.5kw |

4800kg |

1900×2000×1700 mm |

|

ML1300 |

1300×920mm |

18±2 (strokes/min) |

<40m |

7.5kw |

6000kg |

2000×2400×1800 mm |

|

ML1400 |

1400×1000mm |

18±2 (strokes/min) |

<45m |

7.5kw |

6500kg |

2000×2450×1900 mm |

|

ML1500 |

1500×1050mm |

18±2 (strokes/min) |

<45m |

7.5kw |

7000kg |

2000×2500×1930 mm |

|

ML1600 |

1600×1250mm |

16±2 (strokes/min) |

<50m |

11kw |

11000kg |

2170×2560×2130 mm |

|

ML1800 |

1800×1300mm |

16±2 (strokes/min) |

<62m |

15kw |

13500kg |

2240×2800×2230 mm |

|

ML2000 |

2000×1450mm |

16±2 (strokes/min) |

<68m |

15kw |

14800kg |

2300×2900×2306 mm |

Function for use :

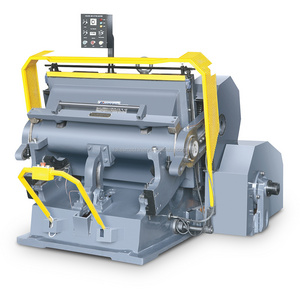

Paperboard die cutting machine is a special equipment for creasing and cutting ordinary cardboard, corrugated cardboard, plastic and leather ingeneral, applicable to printing packaging decoration and plastic industries. The machine is characterized by compact structure,fine workmanship, high precision and easy operation, etc.

Structure:

1.Sliding bearings are made of high quality alloy cooper, thus to get effect of anti-friction and shake reducing.

2.Flywheel is with big mloment of force and heavy pressure.

3.High strength due to one piece casting by using top-ranking material for machine frame.

4.Single plate electromagnetic clutch is sensitive and reliable.

5.With functions of single, continuous and opening dwell operation, dwell range is adjustable.

6.Operating position is reasonably arranged, moving-bed can be opened to its optimum.

7.Safety system is reliable.

Main features:

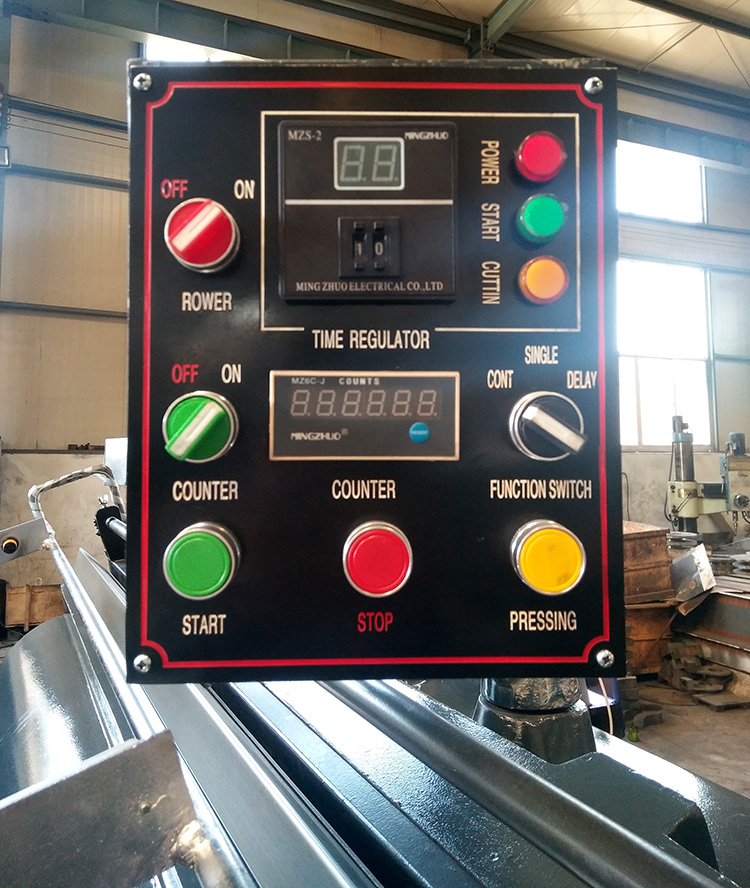

1. This machine has four insurance four function.

2. Insurance: longmen insurance triangle insurance handle insurance electric automatic insurance, and thus more safe and reliable.

3. Function: single cut delay continuous count ; The brake clutch is electric chuck braking clutch, has the brake sensitive insurance coefficient big safety performance is strong, etc.

4.T he template plate frame adjustable board box convenient upper discharge board .

5. And with standard: manual injection fuel supply or the computer automatically on fuel supply configuration. We can manufacture variable frequency speed regulation.

6.The motor is mengniu brand.

About packing and shipment,we can arrange well as customer request:

1) Plastic film wrapping outside;

2) Hard wooden case;

3) Hard steel frame;

a . Get o ne year /12 month guarantee for whole machine , except of easy broken parts.

b. Within 24 hours on-line service or feedback by e-mail.

c. Calling, E-mail ,on-line factory visit or door-to-door service.

d. 5-10 engineers can go abroad for over-seas' training and installation.

e. Top quality, Competitive price, Timely delivery and Heart-to-heart service.