- Product Details

- {{item.text}}

Quick Details

-

Mould material:

-

Aluminum alloy 6063

-

Cavity:

-

Multi Cavity

-

Application:

-

Decoration Cornice

-

Mold life:

-

500000shots

-

Process:

-

Fully CNC Produced

-

Packing:

-

Wooden Case Packing

-

Size:

-

Customized Size

-

Service:

-

Made-to-order

-

Keyword:

-

Cornice Mold

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

China

-

Product Name:

-

Longwell Expanded Polystyrene Mold EPS Foaming Mould Styrofoam Mould

-

Mould material:

-

Aluminum alloy 6063

-

Cavity:

-

Multi Cavity

-

Application:

-

Decoration Cornice

-

Mold life:

-

500000shots

-

Process:

-

Fully CNC Produced

-

Packing:

-

Wooden Case Packing

-

Size:

-

Customized Size

-

Service:

-

Made-to-order

-

Keyword:

-

Cornice Mold

Products Description

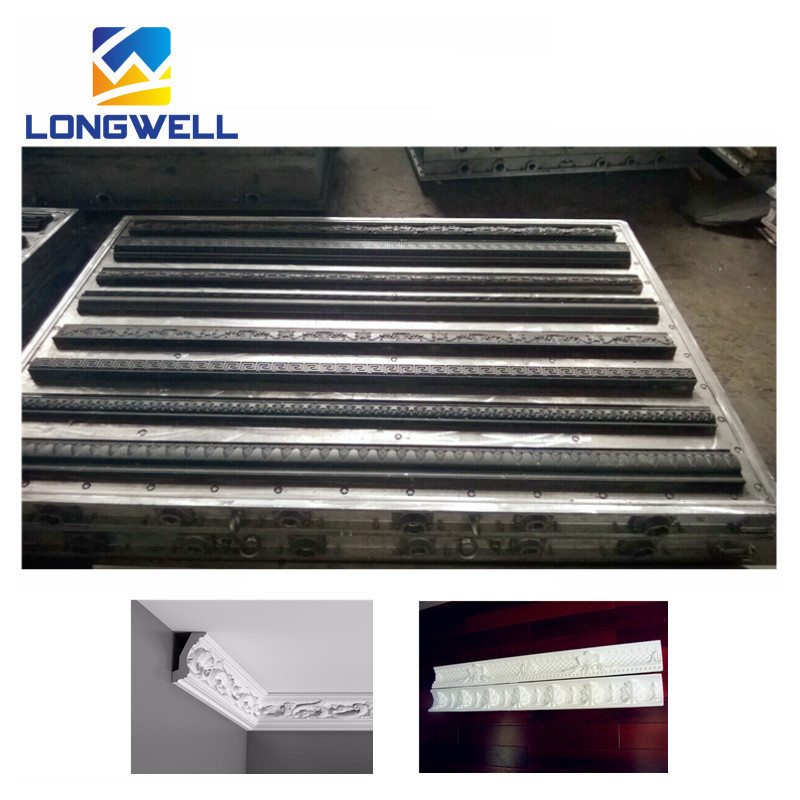

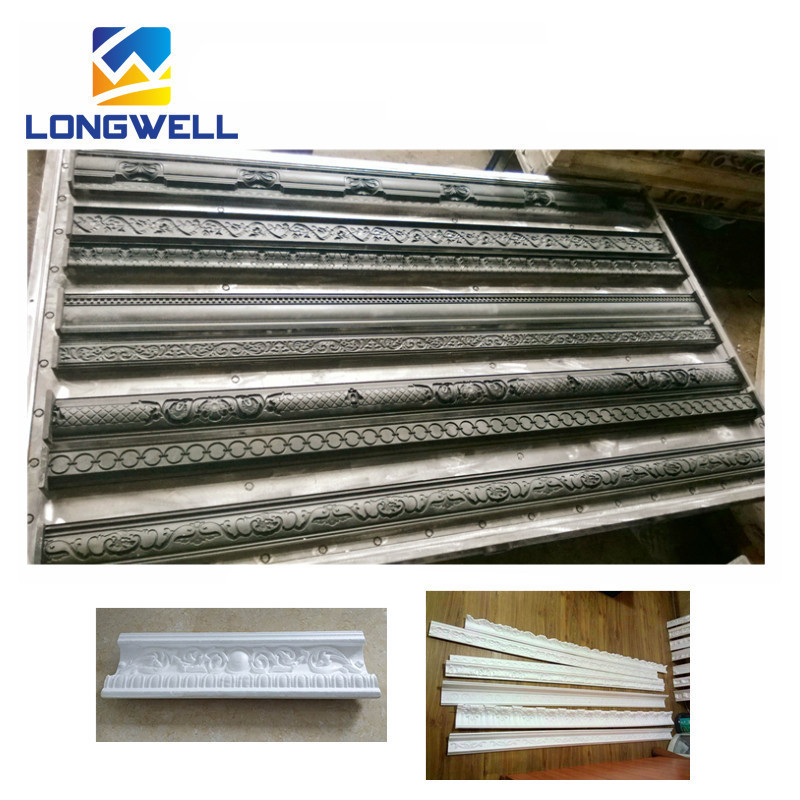

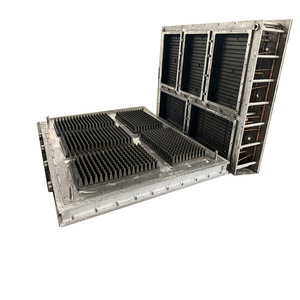

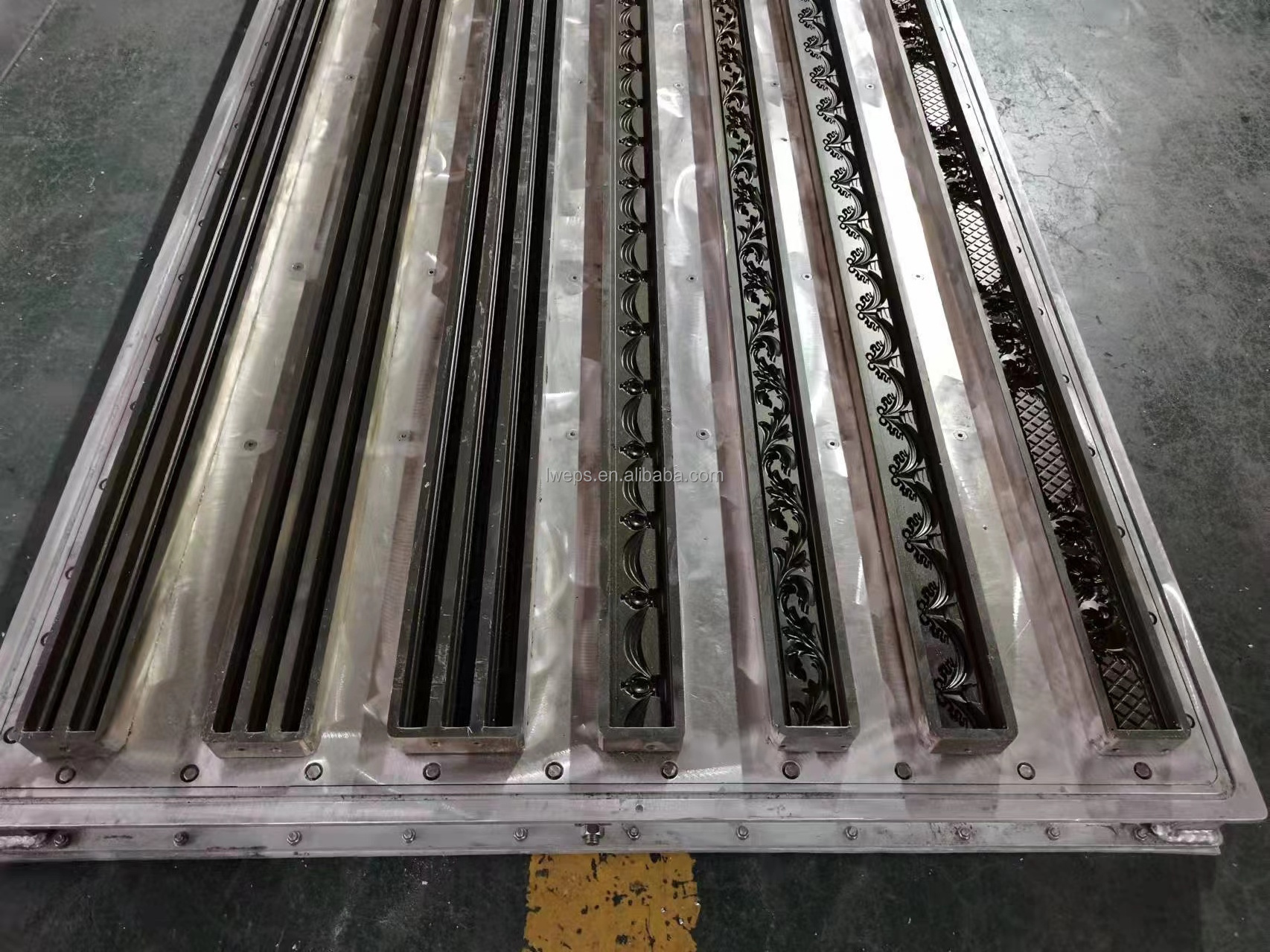

EPS FOAM MACHINE MOLD

|

Product Name

|

Mold for EPS shape molding machine

|

|

Material

|

High quality 6063 aluminum alloy

|

|

Application

|

EPS Packaging Box. Styrofoam Icf Blocks, Decoration Cornice and other EPS Productions

|

|

Package

|

Wooden Case Packaging

|

|

MOQ

|

1 set

|

|

Finished Prodcution

|

Customized

|

|

Service

|

Convert customer's samples to CAD drawing or 3D drawings, test mould before delivery

|

PROCESS:

Finished Productions:

Descriptions of Longwell Expanded Polystyrene Mold EPS Foaming Mould Styrofoam Cornice Mold

1. EPS mold is made of high quality aluminum material, and mould frame is made by extruded aluminum alloy profile, strong and long lasting.

2. EPS mold are processed by CNC machines, mould sizes are precise.

3. All cavities and cores are covered by Teflon coating to guarantee easy demoulding.

2. EPS mold are processed by CNC machines, mould sizes are precise.

3. All cavities and cores are covered by Teflon coating to guarantee easy demoulding.

Advantages of Longwell Expanded Polystyrene Mold EPS Foaming Mould Styrofoam Cornice Mold

1. We can test your mold before delivery,

2. Our engineer have rich experience to make designs.

3. We can convert customer's samples to CAD drawing or 3D drawings.

2. Our engineer have rich experience to make designs.

3. We can convert customer's samples to CAD drawing or 3D drawings.

Applications of

other molds

Hot Searches