Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Inverter:

-

ABB

-

Processing Type:

-

Extrusion Machine

-

Extruder Screw and Barrel Materials:

-

38CrMoAIA1

-

Haul-off Speed:

-

0.5-5m/min

-

Cooling Water Consumption:

-

12-18 m3/h

-

Keywords:

-

Wood Plastic Composited Product Making Machine

-

Finished Product:

-

PVC PE PP WPC Profile, Board,Foam Panel, Flooring, etc

-

Application Field:

-

Construction

Quick Details

-

Screw Design:

-

Double-screw

-

Place of Origin:

-

Jiangsu, China

-

Main Electric Components:

-

Siemens

-

Inverter:

-

ABB

-

Processing Type:

-

Extrusion Machine

-

Extruder Screw and Barrel Materials:

-

38CrMoAIA1

-

Haul-off Speed:

-

0.5-5m/min

-

Cooling Water Consumption:

-

12-18 m3/h

-

Keywords:

-

Wood Plastic Composited Product Making Machine

-

Finished Product:

-

PVC PE PP WPC Profile, Board,Foam Panel, Flooring, etc

-

Application Field:

-

Construction

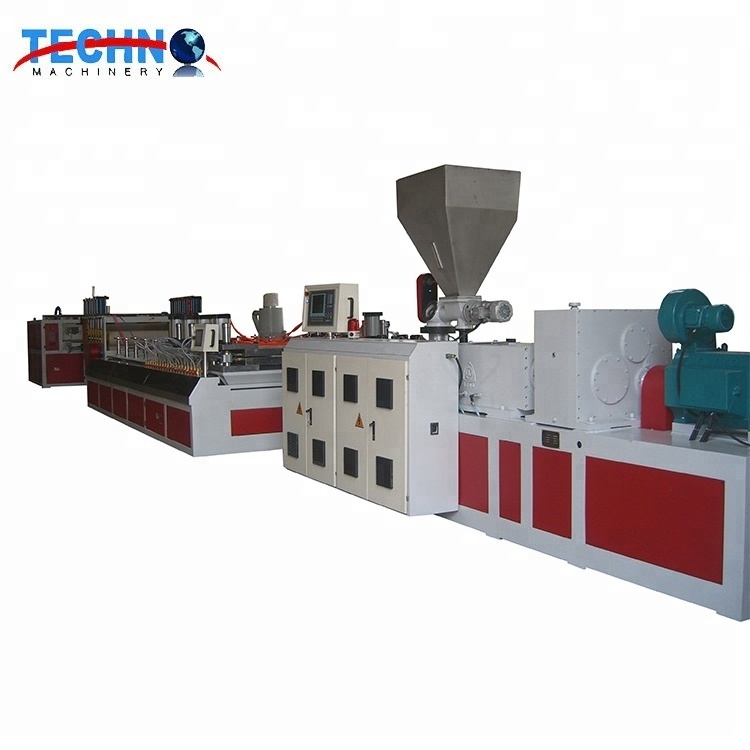

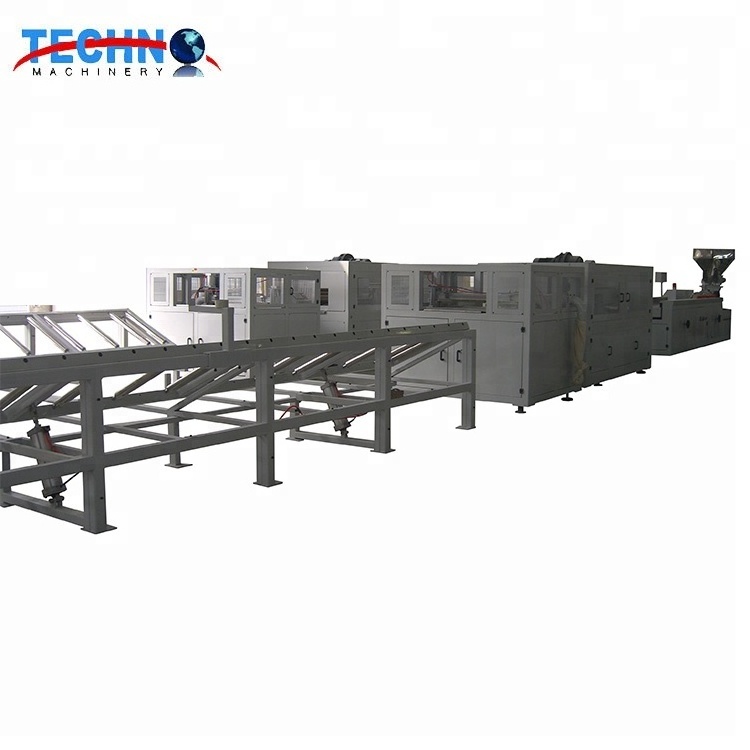

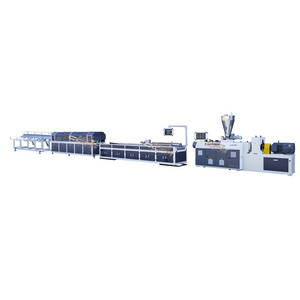

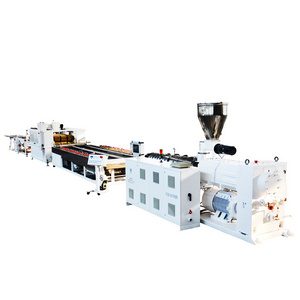

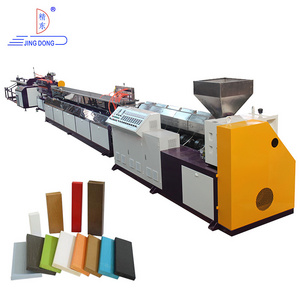

Processing Flow of Wood Plastic Composited Product Making Machine/PVC PE PP WPC Door Floor Decorative Profile Board Panel Extrusion Production Line

Raw material+Wood powder+Additive - Mixing - Conical twin screw extruder - Extrusion mould - Calibrator - Spray cooling - Cutter - Rack - Finished product inspecting and packing

Combination of Wood and Plastic

Thermoplastic: HDPE,LDPE,PP,PVC

Wood Flour: 20-60 mesh

Lubricants, Pigments, Coupling agents, other additives

Illustration of Wood Plastic Composited Product Making Machine/PVC PE PP WPC Door Floor Decorative Profile Board Panel Extrusion Production Line

This WPC profile extrusion line is mainly used in WPC (PVC or PE ) floor, WPC auxiliary profile for the decorative door and small profiles.Chaging the moulds,this wood plastic profile production line can manufacture many different kinds of profiles according to your requrest.

The new wood plastic composite functions same as natural wood,but with better performance.Resistant to water,corrosion and mildew.WPC is a very promising and sustainable green material to achieve durability without using toxic chemicals.Ideal for applications in high moisture environments.Recyclable to meet environmental protection requirements.

Twin Screw Extruder

Vacuum Calibration Bath

Cutter Unit

Tilting Stacker

Mould (This Price is not included in the production line, this price needs to offer back according to the customer's detailed product drawing)

Finished Product

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Wood Plastic Composited Product Making Machine/PVC PE PP WPC Door Floor Decorative Profile Board Panel Extrusion Production Line

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate