- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huayin

-

Voltage:

-

380V/415V

-

Power:

-

24KW

-

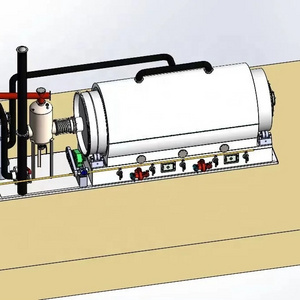

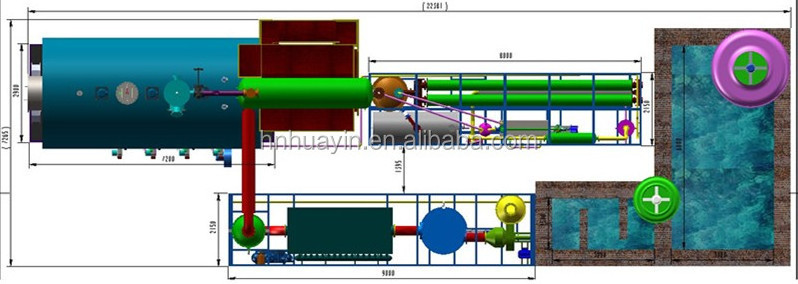

Dimension(L*W*H):

-

9.2*3.14*3.06

-

Weight:

-

39T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Raw Material:

-

Used engine oil , pyrolysis oil , furnace oil , black oil

-

Capacity:

-

1Ton ,2 tons ,3 tons ,4 tons ,5 tons ,6 tons material input

-

Machine structure:

-

Horizontal structure

-

Machine landing area:

-

300-400 square meter

-

Function:

-

mini oil refinery

-

Operators:

-

2 workers per shift

-

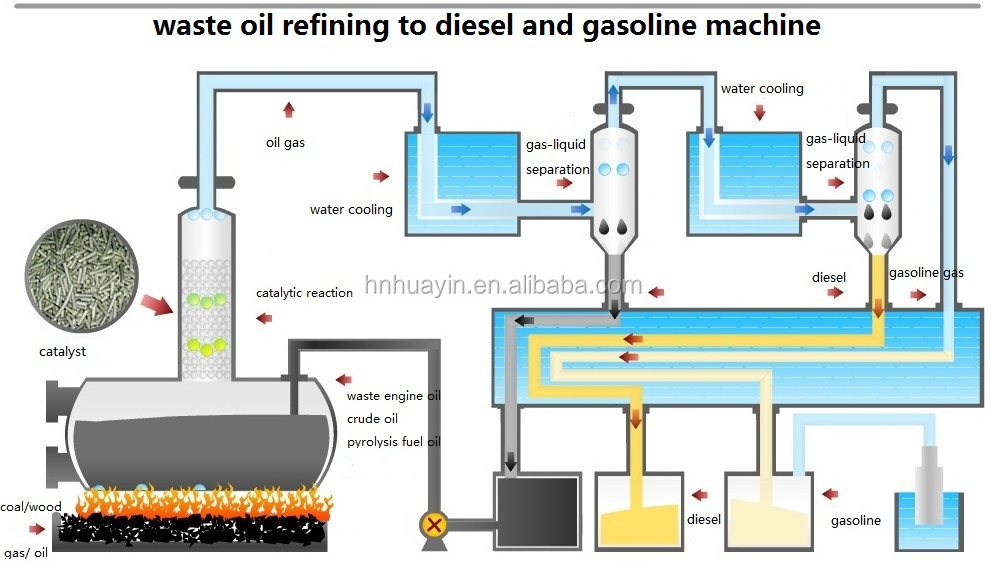

working process:

-

feeding,heating ,cracking,oil gas, cool into crude oil or diesel

-

Factory:

-

over 20 years oil refining machine manufacturer

-

RUNNING MACHINE:

-

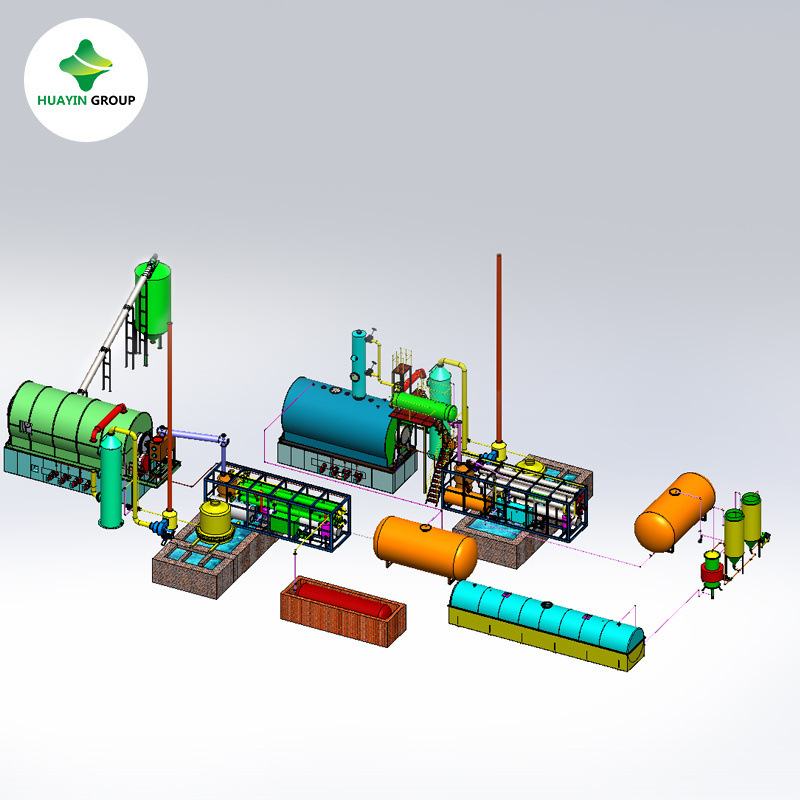

2000 ㎡ test site for 6 setsUsed Oil Recycle Machine For Bunker Oil

-

Certification:

-

ISO9001, CE ISO14001

Quick Details

-

Applicable Industries:

-

Waste Recycling

-

Flow:

-

5-50 T/D

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Voltage:

-

380V/415V

-

Power:

-

24KW

-

Dimension(L*W*H):

-

9.2*3.14*3.06

-

Weight:

-

39T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Raw Material:

-

Used engine oil , pyrolysis oil , furnace oil , black oil

-

Capacity:

-

1Ton ,2 tons ,3 tons ,4 tons ,5 tons ,6 tons material input

-

Machine structure:

-

Horizontal structure

-

Machine landing area:

-

300-400 square meter

-

Function:

-

mini oil refinery

-

Operators:

-

2 workers per shift

-

working process:

-

feeding,heating ,cracking,oil gas, cool into crude oil or diesel

-

Factory:

-

over 20 years oil refining machine manufacturer

-

RUNNING MACHINE:

-

2000 ㎡ test site for 6 setsUsed Oil Recycle Machine For Bunker Oil

-

Certification:

-

ISO9001, CE ISO14001

|

SPECIFICATION OF WASTE OIL DISTILLATION PLANT

|

|

|

|

Capacity

|

3 TON , 5 TON , 10 TON , 30 TON ...

|

|

|

Working type

|

batch type and contnuous type

|

|

|

Avaiable raw material

|

Pyrolysis oil ,used motor oil , furnace oil , mixed waste oil , hydrulic oil , sludge oil etc.

|

|

|

Heating fuel

|

coal , wood , pyrolysis oil , natural gas

|

|

|

Reactor raw material

|

Q245R steel plate , Q345R boiler steel plate or customized support

|

|

|

Machine landing area

|

300-400 square meter (various by different capacity)

|

|

|

Operators

|

2 workers per shift

|

|

|

OUTPUT PRODUCT DATA

|

|

|

|

|||

|

No.

|

End Production Name

|

oil yield

|

Usage

|

|||

|

1

|

Diesel fuel

|

85%

|

sed for diesel engines like trucks , tractors , ships ,power generators etc.

|

|||

|

2

|

Residue oil

|

9%

|

used for distillation machine as heating fuel

|

|||

|

3

|

syngas & impurities

|

about 6%

|

recycled to distillation furnace as heating material

|

|||

|

Item

|

Function

|

|

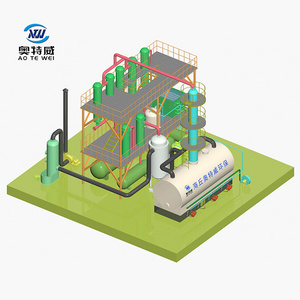

Distilation reactor

|

The waste oil will be pumped into the reactor for refining.

|

|

Distillation column

|

Atmospheric Fractionator Ensure differrent Fraction come Out.

|

|

Condensing device

|

The oil gas will be cooled to liquid oil then flow to the oil storage tank

|

|

Vacuum pump

|

Ensure the distillation machine working under normal pressure.

|

|

Anti back fire device

|

Safety device , prevent the oil gas revert to the reactor.

|

|

Non condensable oil gas recycling system

|

The non condensed oil gas (Syngas ) will be recycled to heating system as fuel.

|

|

Color and smell removal system

|

the last step to remove bad smell and color to yellow diesel oil.

|

|

Dedust system

|

3 layers of ceramic packing dedusting to remove dust and acidity, non- pollution.

|

|

Safety devices

|

Auto releasing pressure device , alarm, safety valve , etc to ensure safety operating.

|

Oil analysis report

Oil product show

Used oil distillation recycle machine installed in Benin

1. All the equipment are certified by CE and ISO

2.Latest integrated design condensing system ,

36 meters condensing pipes ,more cooling area, more effective cooling effect

,

higher oil yield

3.Equipped with

safety valves, auto alarming system, anti-explosion valve, which will guarantee 100% safety

4. Flue tube condenser, cool down the exhaust gas from the burner, protect draft fan and improve dedusting effects.

5. Adopts

ceramic packing Three-layer dedusting system to clean the exhaust gas to reach European pollution control standards.

6.

Automatic submerged welding technology, ultrasonic nondestructive testing

, guarantee the equipment quality

7.Oil pump feeding and discharging, save much manpower.

training as well as Technical support&update Service.

Still have Questions ?

Please Send Us Inquiry

To get latest details !