- Product Details

- {{item.text}}

Quick Details

-

Workpiece speed:

-

6 to 60 RPM

-

Dimension of grinding wheel:

-

750x70x305 mm

-

Speed of grinding wheel:

-

35 m/s

-

Cross stroke of grinding wheel:

-

380 mm

-

Cross rapid traverse of grinding wheel:

-

400 mm/min

-

rolling grinding machine:

-

rolling grinding machine CNC control

-

Weight:

-

approx. 70,000 kg

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

guarantee:

-

twelve months

-

machinery:

-

rolling grinding machine

-

Workpiece speed:

-

6 to 60 RPM

-

Dimension of grinding wheel:

-

750x70x305 mm

-

Speed of grinding wheel:

-

35 m/s

-

Cross stroke of grinding wheel:

-

380 mm

-

Cross rapid traverse of grinding wheel:

-

400 mm/min

-

rolling grinding machine:

-

rolling grinding machine CNC control

-

Weight:

-

approx. 70,000 kg

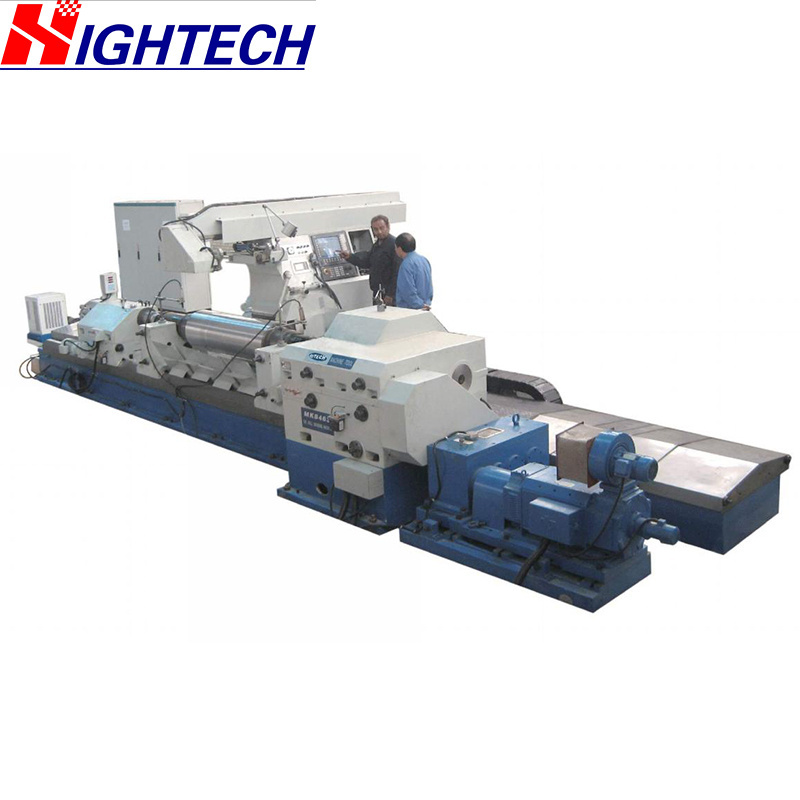

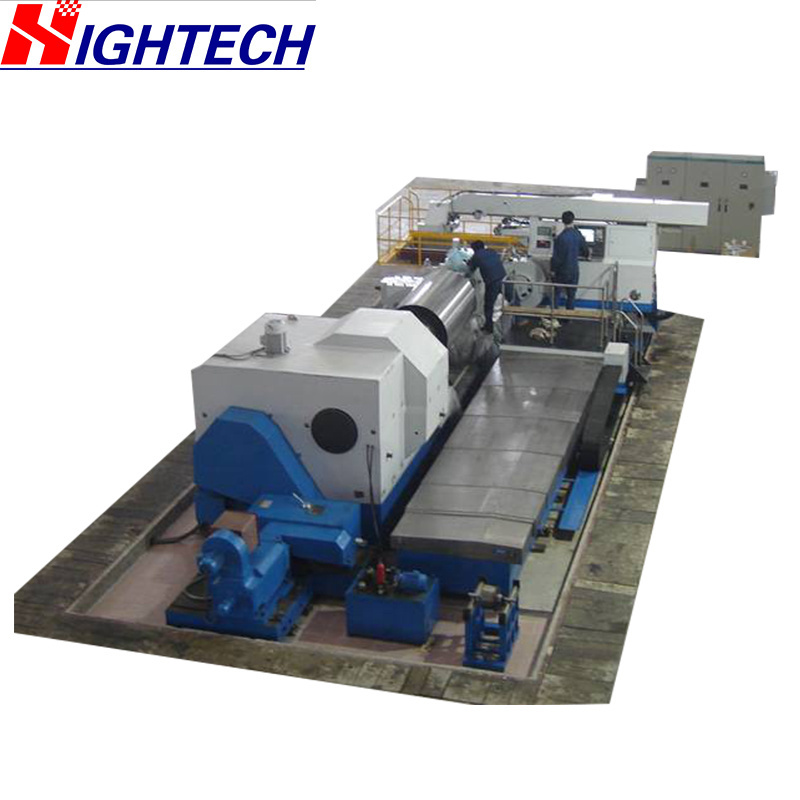

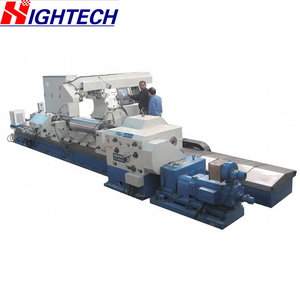

MK8480 rolling grinding machine manufacturer for high precision roller machining CNC automatic roll grinder

1. Main parameter:

|

Max. diameter to be ground (Grinding wheel, OD 750mm) |

800 mm |

|

Min. diameter to be ground (Grinding wheel, OD 750mm) |

120 mm |

|

Max. length to be ground |

5000 mm |

|

Max. weight of workpiece to be ground |

5000 Kg |

|

Workpiece speed |

6 to 60 RPM |

|

Dimension of grinding wheel |

750×70×305 mm |

|

Speed of grinding wheel |

35 m/s |

|

Cross stroke of grinding wheel |

380 mm |

|

Cross rapid traverse of grinding wheel |

400 mm/min |

|

Crown in radius direction |

≤ 1.5 mm |

|

Rapid speed of saddle in Z-axis |

20 – 2500 mm/min |

|

Continual cross feed speed |

0.002 - 1.2 mm/min |

|

Periodical cross feed |

0.003 - 0.12 mm/travel |

|

Measuring range of measuring system |

90 – 820 mm/min |

|

Stroke of tailstock quill |

300 mm |

|

Steady Rest |

120 – 300 – 420 mm |

|

Flow of coolant system |

250 L/min |

|

Motor for workpiece rotation |

45KW |

|

Motor for the grinding wheel |

45KW |

|

Motor for motion of saddle in Z-axis |

41 Nm |

|

Feeding motor for wheelhead in X-axis |

24.5 Nm |

|

U-axis motor for crown |

8 Nm |

|

Motor for measuring device |

8 Nm |

|

Net dimension of the machine |

11,500×3,800×2,600 mm |

|

Net weight |

approx. 70,000 kg |

|

Integrated lubrication |

|

|

Main electrical parts: Schneider in France |

|

|

Coolant system, magnetic separated paper filter |

|

|

Cover for bed paths of grinding wheel support : telescopic stainless steel |

|

|

Control system SINUMERIK 840D (NCU573.4 CPU PⅢ 500MHz) |

|

2. Machine Accuracy with center rest:

Roundness ≤0.002 mm

Cylindrical tolerance ≤0.002 mm/m

Roller body tolerance ≤0.003 mm

Repeated positioning X-axis, 0.005 mm; Z-axis: 0.050 mm

Roughness Ra: 0.2 μm

3. List of main parts:

|

Item No. |

Part Name |

Supplier |

|

1 |

Controller |

Siemens Company in Germany |

|

2 |

Servo motor |

Siemens Company in Germany |

|

3 |

DC motor for wheelhead |

Siemens Company in Germany |

|

4 |

DC motor for rotating workpiece |

Siemens Company in Germany |

|

5 |

DC adjusting speed device |

Siemens Company in Germany |

|

6 |

Ball leadscrew for U-axis & X & X1-axis |

Shuton in Spain |

|

7 |

Special bearings for ball lead-screw |

IBC. Co. in Germany |

|

8 |

Reducing gearbox |

Stober or Alpha in Germany |

|

9 |

Helical rack for Z-axis |

WMH Co. in Germany |

|

10 |

Linear encoder & feedback units |

Heidenhain made by Germany |

|

11 |

Main bearings |

NSK Croup. in Japan |

|

12 |

Hydraulic units |

Atos in Italy |

|

13 |

Automatic lubrication system |

Rexroth products |

|

14 |

Electrical cabinet and air-conditioner |

Famous brand in China |

|

15 |

Shaft coupling |

Brand of KTR made Germany |

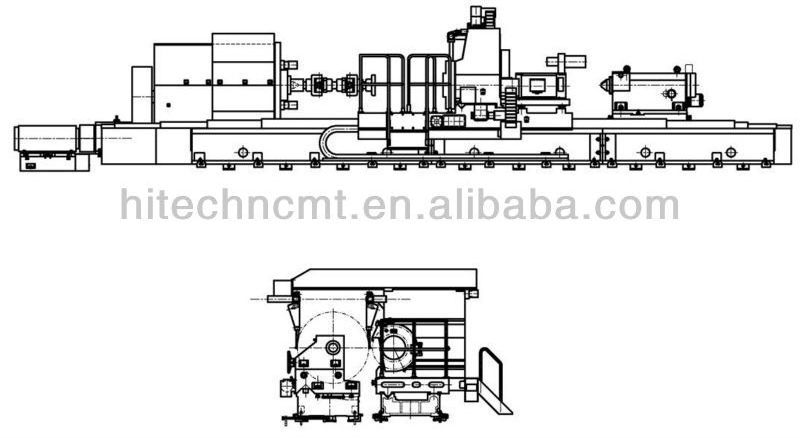

Annx. 1 Fig of Overall view

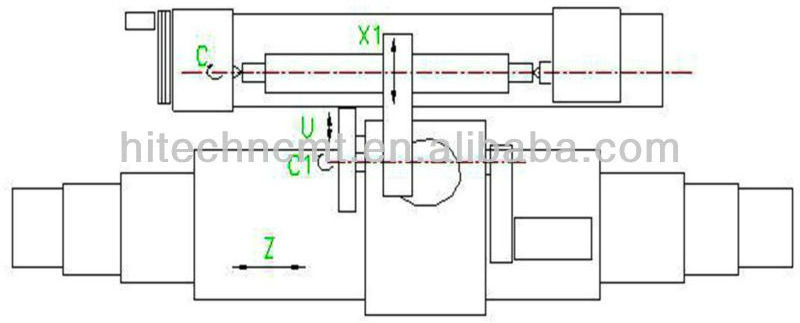

Annx 2. Fig of Axles for control

C1-axis: spindle of grinding wheel, C-axis: rotation of grinding wheel, Z-axis: saddle traverse, X-axis: support of grinding wheel support (closed

loop), U-axis (curve): minim traverse of grinding wheel (closed loop),

X1-axis: support of measuring device (closed loop).

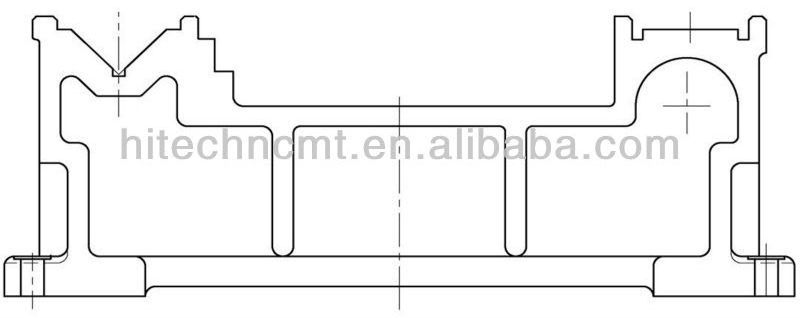

Annex 3. Fig of Bed section for workpiece

Annex 4. Fig of Bed section for grinding wheel support (hydrostatic guideways)

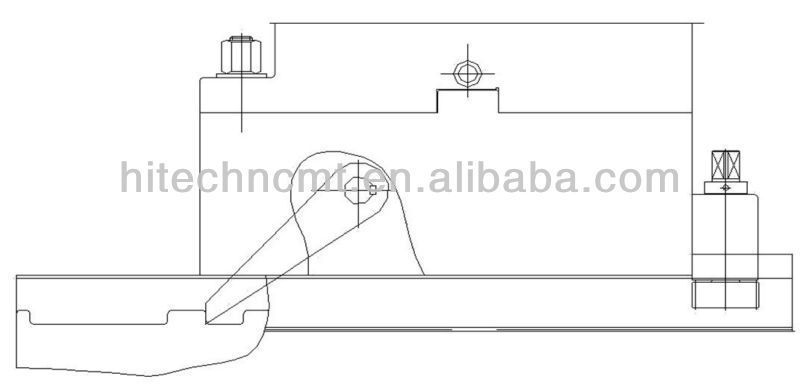

Annex 5. Fig of Lock of Tailstock support

Annex 6. Fig of Dynamic-hydrostatic support of grinder