- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Model Number:

-

refractory brick

-

Brand Name:

-

RongSheng

-

Product name:

-

Magnesia Carbon Brick

-

Cold Crushing Strength, MPa ≥:

-

≥5

-

Refractoriness Under Load, ℃ ≥:

-

1520

-

Thermal expansion at 1000°C(%):

-

0~+0.4

-

refractoriness under load 0.2mpa(°C):

-

1350

-

Application:

-

Industrial Furnaces

-

Price:

-

factory outlets

-

Fe2O3:

-

3-5

-

Apparent Porosity, %:

-

≤16

-

Bulk Density(g/cm3):

-

2.95

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

3-5

-

MgO Content (%):

-

88

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Model Number:

-

refractory brick

-

Brand Name:

-

RongSheng

-

Product name:

-

Magnesia Carbon Brick

-

Cold Crushing Strength, MPa ≥:

-

≥5

-

Refractoriness Under Load, ℃ ≥:

-

1520

-

Thermal expansion at 1000°C(%):

-

0~+0.4

-

refractoriness under load 0.2mpa(°C):

-

1350

-

Application:

-

Industrial Furnaces

-

Price:

-

factory outlets

-

Fe2O3:

-

3-5

-

Apparent Porosity, %:

-

≤16

-

Bulk Density(g/cm3):

-

2.95

Magnesia Carbon Brick Introduction

Magnesia carbon bricks are made from high melting point alkaline oxide magnesium oxide (melting point 2800 ℃) and high melting point carbon materials that are difficult to be infiltrated by slag, with various non oxide additives added. A unburned carbon composite refractory material formed by combining carbon based binders.

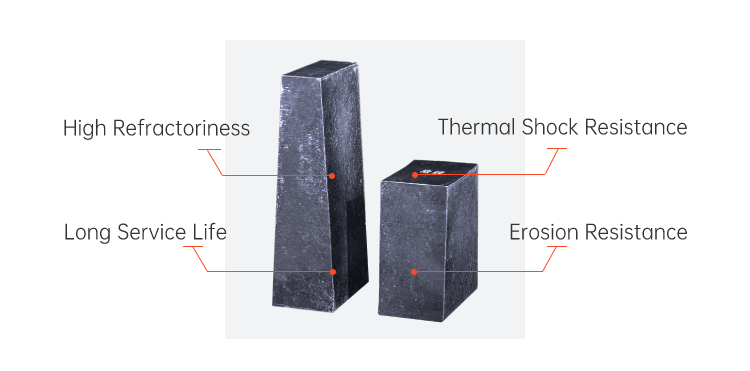

Magnesia Carbon Brick Feature

1. Good fire resistance: Magnesium carbon bricks can maintain stable physical and chemical properties in high-temperature environments, with has a high fire resistance limit.

2. Good thermal conductivity: Magnesium carbon bricks have a low thermal conductivity, which can effectively insulate and improve smelting efficiency.

3. Good corrosion resistance: Magnesium carbon bricks can resist the erosion of corrosive gas media and extend the service life of equipment Service life.

4.Strong slag resistance, good thermal shock resistance, spalling resistance, and low high-temperature creep.

Magnesia Carbon Brick Application

Magnesia carbon bricks have excellent wear resistance and fire resistance, and their performance is stable at high temperatures. So it can be used to manufacture various high-temperature furnaces and containers, as well as the lining of steel smelting furnaces, converters, electric furnaces, refining furnaces, large ladle furnaces, flow arc furnaces, DC arc furnaces, etc

Physical Properties & Chemical Composition

|

Item

|

MT10A

|

MT10B

|

MT14A

|

MT14B

|

MT18A

|

MT18B

|

|

MgO %≥

|

80

|

78

|

76

|

74

|

72

|

70

|

|

C % ≥

|

10

|

10

|

14

|

14

|

18

|

18

|

|

Apparent porosity % ≤

|

4

|

5

|

4

|

5

|

3

|

4

|

|

Bulk density g/cm3 ≥

|

2.9

|

2.85

|

2.9

|

2.82

|

2.9

|

2.8

|

|

Crushing strength Mpa ≥

|

40

|

35

|

40

|

35

|

40

|

35

|

|

Modulus of rupture Mpa ≥

|

6

|

5

|

10

|

8

|

9

|

7

|

| Item | MC8 | MC10 | MC12 | MC14 | MC18 | |

|

apparent

porosity%≤ |

5.0 | 4.0 | 4.0 | 3.0 | 3.0 | |

|

volume

density g/cm3≥ |

3.00 | 3.00 | 2.98 | 2.95 | 2.92 | |

|

cold

crushing strength MPa≥ |

50 | 40 | 40 | 35 | 35 | |

|

chemical

composition% |

Mgo,≥ | 84 | 82 | 76 | 76 | 72 |

| C,≥ | 8 | 10 | 12 | 14 | 18 | |

| application | general use | corrosion resistance | Extra Corrosion Resistance | |||

The bricks are packed on wooden pallet with papers in each layer and PP film wrapped outside of the whole pallet.