- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

50kHz-800kHz

-

Application:

-

Welding

-

Brand:

-

RONEN

-

Certification:

-

ISO9001:2008

-

Material:

-

steel, stainless steel, aluminum, copper, titanium

-

Shape of tube:

-

round/square/rectangular/oval pipe/special pipe

-

Voltage:

-

three phase 220-450V, 50-60HZ

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RONEN

-

Power supply:

-

10kW-3000kW

-

Frequency:

-

50kHz-800kHz

-

Application:

-

Welding

-

Brand:

-

RONEN

-

Certification:

-

ISO9001:2008

-

Material:

-

steel, stainless steel, aluminum, copper, titanium

-

Shape of tube:

-

round/square/rectangular/oval pipe/special pipe

-

Voltage:

-

three phase 220-450V, 50-60HZ

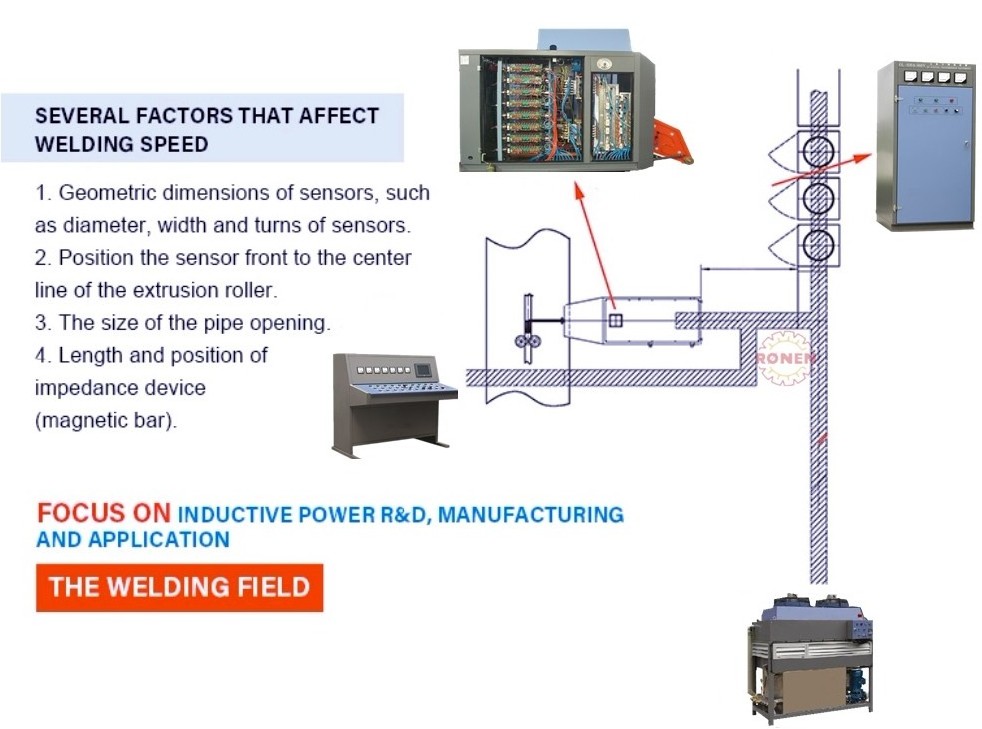

Solid state high frequency tube welder for carbon steel, aluminum, copper, stainless steel tube & pipe welding featured with high efficiency and reliable.

Power scope: 10kW-3000kW

Frequency scope: 50kHz-800kHz

Rated DC voltage: 450V

Power grid voltage: 220V~450V,50/60Hz,3-phase

Full digital rectifying control board

The new generation of solid state welding machine, using the field programmable logic gate array (FPGA) main control chip, the main frequency up to 100M, 16 bit A/D conversion chip (the original control board using 8 bit A/D conversion chip), the high precision of the data resolution; the cancellation of all the adjustable potentiometers on the board (12 control potentiometers in the original control board), color touch screen control System and parameter setting, debugging and operation are simple and intuitive. All parameters in the rectifier board can be transmitted to the host computer for display and recording through communication. The unique parallel working mode of FPGA ensures that the modules of the program operate at high speed and independently.

All digital inverter control board

The new generation of solid state high frequency welder has integrated the advanced control concept of similar products in the world. The field programmable logic gate array (FPGA) is used as the main control chip to realize the advanced control technology such as the fixed angle lock phase control, the upper / lower frequency locking protection and so on, which makes the equipment running more stable and more efficient.

The new bridge inverter technology design

The new technology inverter bridge plate is made of the 12mm purple copper plate surface plating technology and the oval inner channel cooling, the surface of the water cooled plate is more smooth and the cooling effect is better. The temperature of the power element is better than the original inverter bridge under the same environment (using the tin plating process of the 5mm thick purple copper plate and the surface welding copper tube cooling mode) Low 3~5 degrees Celsius improves the safety of power devices.

OUR SUCCESSFUL PROJECT

Ronen Group co., Ltd is established at 1997, has a large modern standard industrial plant. Ronen Group is a professional mechanical equipment manufacture for design, producing and sales, our company has a group of research technicians who have many years research and development experience. We equipped with independent research and development department,design department, welding workshop, assembly workshop, checkout room, the assessment team and thorough manufacturing system etc... Ronen company passed ISO9001:2008 certification and strictly follow this system for production.etc.

OUR PRODUCT CATALOGUE

Q: Are you manufacturer?

A: Yes, We are the leading manufacturer.

Q: How to order?

A: Please send us your inquiry by email, send message though Alibaba or we chat.

Q: What is the whole business flow cooperation with us ?

A:

1. Firstly,send your inquiry to us, make us have learned your requirement

2. we will be drawing a proforma invoice according to your requirement ,and start production after you finished to pay 30% deposit.

3. All of the goods, packing details, and B/L copy will be send to buyer after finished production. We will arrange shipment and provide original B/L after the buyer finished to pay the balance.

Q: What advantages we have?

A: Rich experience: We have been in this line for 21 years . we can provide solution according to the problem of the buyer meet in the production process