- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

5500 KG

-

Power (kW):

-

40

-

Name:

-

PVC/Acrylic film laminating machine

-

Thickness of panel:

-

5-40mm

-

Panel size:

-

4'x8'/6'x8'

-

Working speed:

-

5-17m/min

-

Panel:

-

MDF/chipboard/CPL/HPL/ gypsumboard etc.

-

Machine size:

-

11800(L)*5000(W)*3000mm(H)

-

Weight:

-

5500KGS

-

Production time:

-

45 days

-

Heating system:

-

Oil heating system

-

Certifications:

-

CE & ISO9001

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Hessan

-

Machine Type:

-

laminating press machine

-

Warranty:

-

1 Year

-

Weight (KG):

-

5500 KG

-

Power (kW):

-

40

-

Name:

-

PVC/Acrylic film laminating machine

-

Thickness of panel:

-

5-40mm

-

Panel size:

-

4'x8'/6'x8'

-

Working speed:

-

5-17m/min

-

Panel:

-

MDF/chipboard/CPL/HPL/ gypsumboard etc.

-

Machine size:

-

11800(L)*5000(W)*3000mm(H)

-

Weight:

-

5500KGS

-

Production time:

-

45 days

-

Heating system:

-

Oil heating system

-

Certifications:

-

CE & ISO9001

Item: PUR Hot Melt Glue Single Side Panel Laminating Machine

Model: HY-PUR-1400A

Advantages:

♦ More than 10 years production experiences;

♦ Provide overseas service;

♦ Acquired ISO9001 & CE certificates;

♦ Good experiences in world market,products are exported more than 20 countries.

Specifications:

This is flat surface lamination machinery best to run with PUR hot melt, suitable for various material in the market.PUR hot melt glue is able to provide quick chemical reaction with superior bonding.

1 ) Included : Indexing Table, Cleaning Device , Preheating Tunnel and connected with Driving Rollers Conveyer.

2 ) Single side spreading with both oil heating dosing and applicator rollers. Precise heating ability create a stable and uniform temperature, combined with glue melting unit to provide best production output capability.

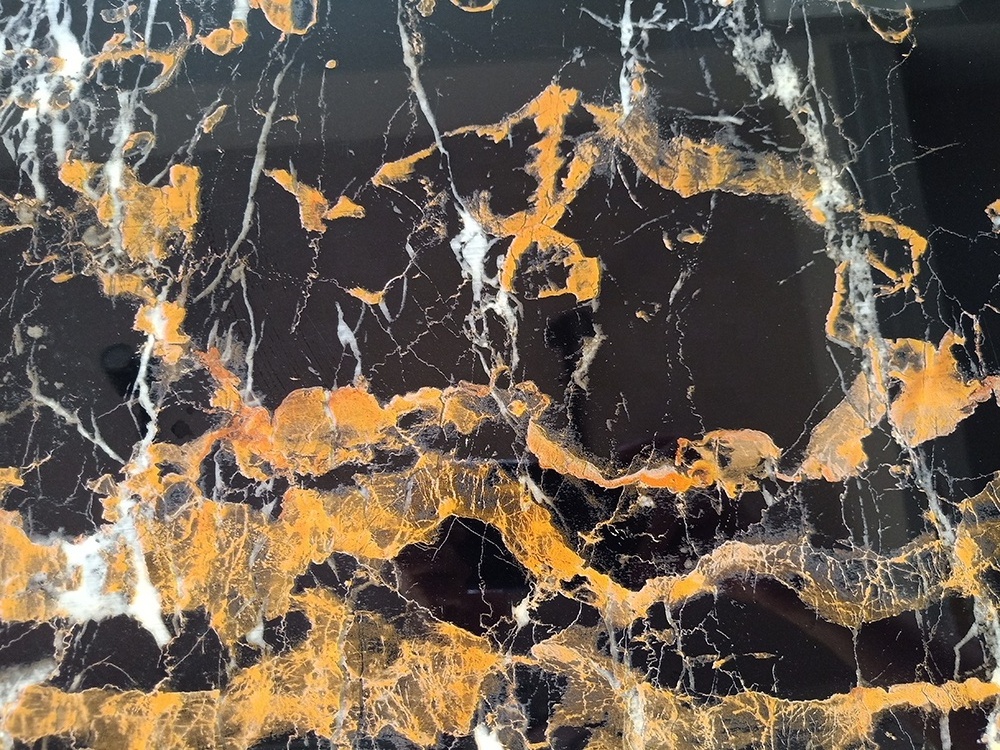

3 ) Semi-auto foil unwinding station on top of calendar press rollers, which suitable for various foil/film material lamination. Easy, flexible and effective, with minimum wastage of material.

4 ) Two set cold calendar pressing rollers providing sufficient pressure for various lamination combination. Adjustable pressure, possible to attach with expanding shaft and power bake for film lamination.

5 ) Driving rollers conveyer for exist may come with protection film lamination roller.

| FUCTIONAL PARAMETER | |

| Model No | HY-PUR-1400A |

| Dimension Of Product (mm) | 11800*5000*3000MM |

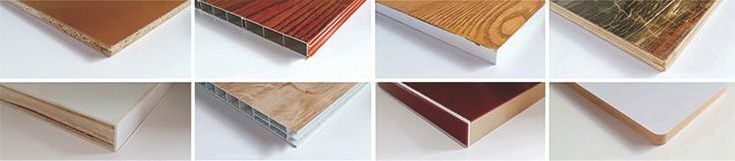

| Base Material | MDF, Partical board, Plywwod, PVC BOARD, Aluminum panel |

| Surface Material | PVC,PET,Acrylic sheet, HPL Sheet, Aluminum sheet, CPL ETC. |

| Glue | PUR hot melt glue, PVAC cold glue; |

| Finished Product | Furniture panel, Door panel, Kichent cabinet; |

| TECHNICAL PARAMETER | |

| Design | Researches and develops voluntarily |

| Running Speed | 25M per Minute |

| Heating Power | 31.2kw |

| Pressing System | Pneumatic |

| Heating System | Oil heating system |

| Eletrical Part | Schneider |

| Color | Yellow and white |

| Certification |

CE and ISO:9001

|

| Payment Terms |

TT (Bank transfer), LC(LC at sight), Western Union, Money Grams, Trade Assurance |

| Supply Ability | 100 set per month |

| Delivery Time | Standard product 4 weeks, customized product 6-12weeks |

| Packaging Details | Plastic protestion foil and wood case |