- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Cusomize

-

Dimension(L*W*H):

-

different as each model

-

Weight:

-

different each model as

-

Product name:

-

Rotary Sceen

-

Keyword:

-

Rotary Vibrating Separator

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel

-

Color:

-

Customers' Request

-

Feature:

-

High Screening Efficiency

-

Commodity:

-

Vibration Screen Sieving Machine Vibro Separator

-

Installation:

-

Engineer Guide Onsite

-

Capacity:

-

100Kg-10Tons/hour

-

Advantage:

-

High Output

-

Local Service Location:

-

Egypt, Italy, Viet Nam, Philippines, Brazil, Indonesia, Pakistan, Thailand, Malaysia, Australia, Sri Lanka, Tajikistan

-

After-sales Service Provided:

-

Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

SGE/CE/ISO

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LZZG

-

Voltage:

-

Cusomize

-

Dimension(L*W*H):

-

different as each model

-

Weight:

-

different each model as

-

Product name:

-

Rotary Sceen

-

Keyword:

-

Rotary Vibrating Separator

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel

-

Color:

-

Customers' Request

-

Feature:

-

High Screening Efficiency

-

Commodity:

-

Vibration Screen Sieving Machine Vibro Separator

-

Installation:

-

Engineer Guide Onsite

-

Capacity:

-

100Kg-10Tons/hour

-

Advantage:

-

High Output

-

Local Service Location:

-

Egypt, Italy, Viet Nam, Philippines, Brazil, Indonesia, Pakistan, Thailand, Malaysia, Australia, Sri Lanka, Tajikistan

-

After-sales Service Provided:

-

Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

SGE/CE/ISO

Products Description

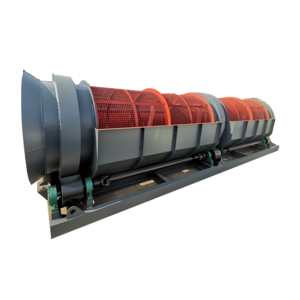

Trommel Screen

LZZG

trommel screens are designed to minimize setup time and be easy and convenient to service. We havperfected the ability to size and customise trommel screens with different materials to suit the application, such as the patented product trommel sand washer.

Trommel drum cylinder is tilted on the rack. The motor is driven by the reducer to rotate the drum unit around its axis. After the material enters the drum device, due to the tilting and rotation of the drum device, the material on the screen surface is flipped and rolled, agglomerated materials crushing, and meanwhile the materials blocked in the screen mesh can be ejected to prevent the sieve hole from blocking. So that the qualified material (the product under the screen) is discharged through the discharge port at the bottom of the trommel screen, and the unqualified material is discharged through the discharge port at the tail of the trommel screen.

Technical Parameters

|

Model

|

Feed Size (mm)

|

Capacity (t/h)

|

Screen Panel (mm)

|

Angle (°)

|

Power (kw)

|

Weight (kg)

|

Overall Size

(mm)

|

|

GT1040

|

≤ 50

|

30-60

|

1000*4000

|

6

|

3

|

1500

|

5500*1460*2340

|

|

GT1240

|

≤ 50

|

30-100

|

1200*4000

|

6

|

5.5

|

1900

|

5500*1680*2480

|

|

GT1560

|

≤ 50

|

30-150

|

1500*6000

|

6

|

11

|

2700

|

6800*2100*4400

|

|

GT1860

|

≤ 50

|

30-200

|

1800*6000

|

6

|

15

|

5010

|

8490*2400*4680

|

|

GT2160

|

≤ 50

|

30-200

|

2100*6000

|

6

|

18.5

|

6360

|

8490*2760*5000

|

|

GT2460

|

≤ 50

|

30-250

|

2400*6000

|

6

|

18.5

|

7200

|

8490*3020*5200

|

|

GT3060

|

≤ 50

|

30-300

|

3000*6000

|

6

|

30

|

8800

|

850083660*5800

|

|

GT3080

|

≤ 50

|

30-300

|

3000*8000

|

6

|

30

|

9400

|

8800*3660*5800

|

Detailed Images

Features & Benefits

1. Adopting rolling conveying, the friction coefficient is small, and the sieve hole is not easy to clog.

2. The drum support adopts integral through-shaft structure, which runs smoothly, does not vibrate and has low noise.

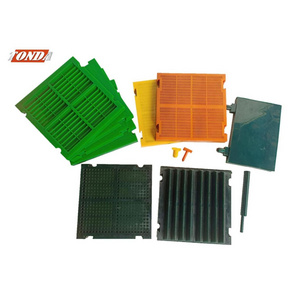

3. The internal drum screen fittings are designed separately, which is simple in structure and convenient in replacement and maintenance.

4. The drum body adopts an effective fully sealed structure, without dust and pollution.

5. Safe and reliable operation, adopting deceleration drive, high transmission efficiency.

6. Customized screen, high screening efficiency, long service life and low maintenance cost.

7. Equipped with sprayer, proficient in both wet and dry applications.

2. The drum support adopts integral through-shaft structure, which runs smoothly, does not vibrate and has low noise.

3. The internal drum screen fittings are designed separately, which is simple in structure and convenient in replacement and maintenance.

4. The drum body adopts an effective fully sealed structure, without dust and pollution.

5. Safe and reliable operation, adopting deceleration drive, high transmission efficiency.

6. Customized screen, high screening efficiency, long service life and low maintenance cost.

7. Equipped with sprayer, proficient in both wet and dry applications.

Working Site

Packing & Delivery

Exhibition

Hot Searches