- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

3200*1700*1900

-

Weight (KG):

-

500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

counting and filling machine

-

Advantage:

-

100% Accuracy

-

Model:

-

LTEC

-

Working range:

-

2-9999pcs (adjustable)

-

capacity:

-

40-90 bottles/min (30-100pcs/bottle)

-

Conveyor Belt Length:

-

2400mm

-

Machine Weight:

-

500kg

Quick Details

-

Capacity (bottle/min):

-

10 - 120 bottle/min

-

Bottle Capacity (pcs/bottle):

-

15 - 150 pcs/bottle

-

Capacity (pcs/h):

-

162000 pcs/h

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

3200*1700*1900

-

Weight (KG):

-

500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

counting and filling machine

-

Advantage:

-

100% Accuracy

-

Model:

-

LTEC

-

Working range:

-

2-9999pcs (adjustable)

-

capacity:

-

40-90 bottles/min (30-100pcs/bottle)

-

Conveyor Belt Length:

-

2400mm

-

Machine Weight:

-

500kg

Products Description

LTEC-series Automatic Electronic counting machine

The High Speed Counting Machine is special for counting chewing gums, etc. The advantage of the machine is no need change mould when you change the counting object, only adjusting the counting table height by Easy Adjust wheel. The machine comes with Touch screen operation and PLC Control for convenient running.

Main Technical Data

|

Model Name

|

LTEC-8

|

LTEC-16

|

LTEC-24

|

LTEC-32

|

|||

|

Hopper Volume

|

20L

|

40L

|

45L

|

80L

|

|||

|

Capacity

|

10-20bottles/min

|

60-70bottles/min

|

80 bottles/min

|

40-120bottles/min

|

|||

|

Filling Quantity

|

2-9999pcs/bottle

|

15-9999pcs/bottle (Adjustable)

|

|

|

|||

|

Bottle Size

|

Diameter: 30-75mm

Height:40-250mm

|

|

|

Diameter: 30-90mm

Height:40-250mm

|

|||

|

Counting Size

|

Thickness: 3-10mm

Diameter: 3-15mm

Length: 3-30mm

|

|

|

Thickness: 3.5-10mm

Diameter: 3.5-15mm

Length: 3.5-30mm

|

|||

|

Compressed air

|

0.5Mpa

|

|

|

|

|||

|

Conveyor Belt Length

|

|

2400mm

|

2400mm

|

3000mm

|

|||

|

Machine Weight

|

120kg

|

500kg

|

750kg

|

1000kg

|

|||

|

Machine Size(mm)

|

660*1280*780

|

600*2400*1670

|

2000*1600*1680

|

2200*1400*1680

|

|||

Features

1.Compatibility, high accuracy, wide application and use of the Company's original anti-dust photoelectric detection of high technology.

2.Vibratory cutting materials do not damage.

3.A high degree of intelligence, with no bottle is not the number of self-fault detection alarm and many other control functions.

4.Compact structure, stability and durability, and no regular replacement parts, small footprint, the use of low-cost.

5.To facilitate the replacement of species, can automatically take-off and landing, demolition cleared without any tools, convenient and quick.

6.Chinese dialogue control panel, can store 10 ~ 20 group of species parameters, adjusted to facilitate the use of special.

7.Fully automatic operation, with the Upper and Lower Union Road, intelligent control of processes, coordination, and no special operation, labor-saving devices.

8.Low prices, especially for small-volume, variety and more manufacturers use.

9.Control chip imported to the United States, photoelectric sensors for Taiwan's imports.

3.A high degree of intelligence, with no bottle is not the number of self-fault detection alarm and many other control functions.

4.Compact structure, stability and durability, and no regular replacement parts, small footprint, the use of low-cost.

5.To facilitate the replacement of species, can automatically take-off and landing, demolition cleared without any tools, convenient and quick.

6.Chinese dialogue control panel, can store 10 ~ 20 group of species parameters, adjusted to facilitate the use of special.

7.Fully automatic operation, with the Upper and Lower Union Road, intelligent control of processes, coordination, and no special operation, labor-saving devices.

8.Low prices, especially for small-volume, variety and more manufacturers use.

9.Control chip imported to the United States, photoelectric sensors for Taiwan's imports.

Details Images

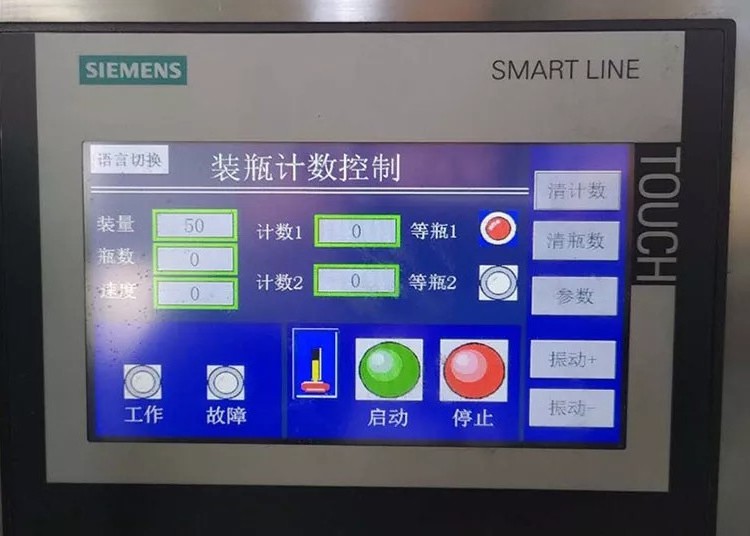

Smart Touch Screen

With Siemens touch screen, various parameters and measurement can be set according to requirements, and multiple languages are supported

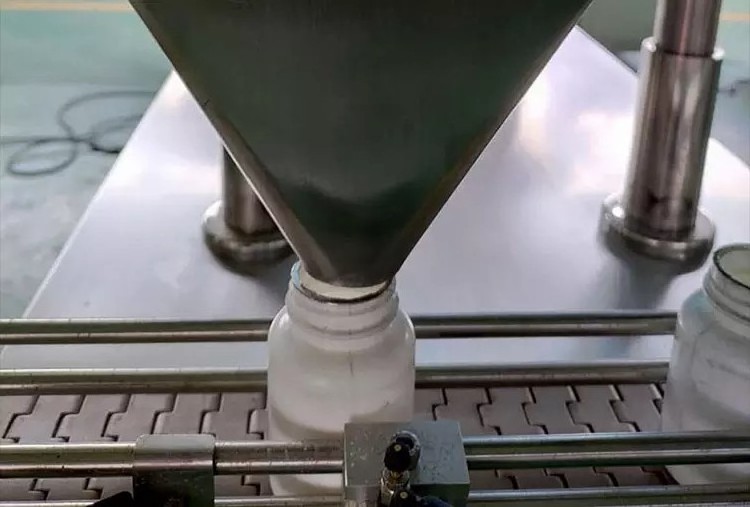

Adjusting Device

The height of the feed opening can be adjusted freely within a certain range to adapt to bottles of different sizes.

Feeding Trough

Can be customized according to customer requirements

Multi-stage Vibration Blanking Device

Effective separation and sorting of materials of different specifications, adjustable vibration frequency, low noise

Conveyor Belt Speed Controller

The speed can be adjusted according to the actual loading

Photoelectric Sensor

It adopts Japan's Panasonic photoelectric eye, which is sensitive, easy to adjust, has the function of pause when there is no bottle, and self-checking. It is suitable for bottles of different colors and specifications.

High-performance Piracy System

The upper and lower closure design has obtained the national new patent, No damage to materials when working

Precision Electrical Components

Adopt branded precision electronic components, safe and stable, reasonable layout, convenient maintenance

Automatic Counting Line

Automatic Counting Line

In addition to a single machine, we can also design a complete set of production line according to your needs.As each machine cooperates perfectly in order, it greatly improves not only the efficiency but also the quality and grade of product packaging.

Hot Searches