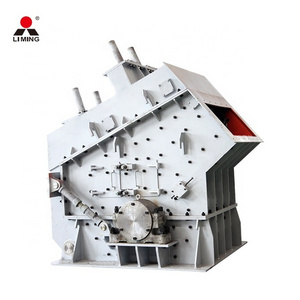

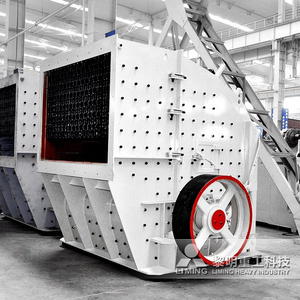

The two-stage crusher is suitable for the cinder, slag, slag, shale, gangue and building of calcite, limestone and brick factory

Waste, construction waste

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HJ

-

Dimension(L*W*H):

-

2450*1020*1750mm

-

Weight:

-

5200 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Stone Crusher

-

Keyword:

-

Fine Impact Crusher

-

Processed Materials:

-

Hard Stone

-

Max feeding size:

-

200mm

-

Color:

-

Customers' Requirements

-

Test&Installation:

-

Under Enginees Guidence

-

Spare parts supply:

-

Lifelong Provide

-

Function:

-

Rock Breaker Crush Machine

-

Price:

-

Competetive (can Discuss

-

Market:

-

Global

Quick Details

-

Application:

-

stone crusher

-

Capacity(t/h):

-

200~300

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HJ

-

Dimension(L*W*H):

-

2450*1020*1750mm

-

Weight:

-

5200 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Stone Crusher

-

Keyword:

-

Fine Impact Crusher

-

Processed Materials:

-

Hard Stone

-

Max feeding size:

-

200mm

-

Color:

-

Customers' Requirements

-

Test&Installation:

-

Under Enginees Guidence

-

Spare parts supply:

-

Lifelong Provide

-

Function:

-

Rock Breaker Crush Machine

-

Price:

-

Competetive (can Discuss

-

Market:

-

Global

Product Description

The upper and lower two stages of double rotors smash the two sets of rotors connected with each other, so that the materials smashed by the upper rotor are produced again by the hammerhead of the lower rotor which rotates rapidly. The materials in the cavity collide with each other rapidly and smash each other, so as to achieve the effect of hammer powder and material powder, and directly discharge them.There is no screen bottom, high humidity material, no blocking. The traditional crusher is equipped with screen. When the moisture content of material is high, the motor will be burnt out.

Advantages of two-stage crusher:

1. two-stage no screen crusher, no requirement for material moisture content, and the production process is not blocked, high fineness, rainy days do not affect production.

2. The two-stage crusher adopts high alloy wear-resistant hammer head. The hammer head and handle are used in combination, only the hammer head is replaced, not the handle. After the hammer head is worn, it does not need to be repaired. The moving position is used repeatedly. A pair of hammerheads can be used with three hammerheads.

3. The two-stage crusher adopts two sets of rotor shaft ends equipped with flywheel. The flywheel can adjust the periodic speed fluctuation of operation, make it run evenly and stably, increase the rotation inertia, overcome the movement resistance, and save more than 20% power.

4. This equipment integrates the two-way gap adjustment technology, which can freely control the granularity of the equipment discharge. Moreover, the machine body is very stable when the equipment is running, and there is no need to install the foundation, which makes the production more humanized.

5. it can be opened and closed easily by one person, which is not only light, fast, safe and reliable, but also convenient for maintenance.

Installation method of two-stage crusher

1. The equipment shall be installed at the level of concrete foundation and fixed with anchor bolt.

2. Pay attention to the main body and vertical and horizontal during installation.

3. After some bolts are installed, check whether they are loose and whether the bin door is tightened as required.

4. Configure the power cord and power control switch according to the equipment.

5. Check whether the empty load test, test and production are normal.

Application scope

Double stage crusher is also called double stage crusher, double stage no screen bottom crusher, double stage hammer crusher and double stage no screen bottom crusher. Double stage crusher is applicable to the crushing of coal slag, slag, slag, shale, coal gangue, construction waste, construction waste and other materials in the factories of calcite, limestone and brick. It solves the problem of using gangue and coal cinder as the additive and internal fuel in the factories of brick, as well as gangue and shale The production of standard brick, hollow brick high wet material crushing problem. The machine is equivalent to two hammers combined into one, reasonable combination into a whole, two sets of rotors are used in series.

Application fields:

Medium size crushing of various raw materials and ores in industries such as brick and tile, cement, building materials, refractory materials, coal mines, power plants, etc.

Applicable materials:

Coal, gangue, sand head, shale, raw material, clinker, cinder, granite, marble, basalt, limestone, quartzite, pebble, iron ore, copper ore, etc.

Detailed Images

The upper and lower crushing cavities of this series of products, through the motor pulley, are driven by the V-belt and the groove pulley. The hammerhead installed on the rotor rotates rapidly, crushing the materials in the upper crushing cavity composed of the fixed lining plate, the movable hammerhead and the side lining plate, and then entering the lower crushing cavity to finely crush the materials, thus increasing the crushing stroke of the materials and making the materials more Even, the output is higher.

Size Information

Model you can chose

|

Model

|

Feed Particle Size

(mm)

|

Productivity

(t/h) |

Power(kw)

|

Whole Machine Size

(mm)

|

|

SCF600*400

|

≤110

|

10-15

|

18.5+18.5

|

2450x1020x1700

|

|

SCF600*600

|

≤110

|

20-25

|

22+22

|

2450x1280x1650

|

|

SCF800*600

|

≤120

|

40-50

|

45+45

|

3760x1314x2100

|

|

SCF800*700

|

≤120

|

45-60

|

45+55

|

3485×1400×2254

|

|

SCF800*800

|

≤180

|

50-60

|

45+45

|

3760x1840x2100

|

|

SCF900*800

|

≤180

|

50-70

|

75+55

|

3950×1750×2280

|

|

SCF1000*800

|

≤180

|

70-80

|

75+55

|

4100x1840x2450

|

|

SCF1100*1000

|

≤200

|

70-100

|

110+90

|

4086×2030×2337

|

|

SCF1400*1200

|

≤200

|

90-110

|

132+160

|

5800×2658×3210

|

Related Products

Packing&Shipping

After Sales Service

Safe operation:

1

. Wear labor protection articles correctly and carefully during patrol inspection.

2. Regularly check the wear of the hammer head, observe whether there is crack on the hammer head and whether the connection of the hammer head vibrates, and make corresponding treatment and report to the superior leaders.

3. The particle size of the material crushed by the crusher shall not exceed the specified maximum particle size.

4. Pay attention to the operation sound of the crusher, check whether the hydraulic and lubrication system is normal, contact with the central control in time in case of any abnormality, take corresponding measures according to the situation and report to the superior leader in time.

5. Regularly check whether the protective cover of the drive belt and coupling is loose, and whether the anchor bolt is loose, otherwise, it shall be fastened in time.

6. Regularly check the temperature and sound of the bearing and the vibration of the machine body. In case of any abnormality, inform the relevant personnel for inspection.

7. When the equipment is in operation, the crusher has abnormal crushing sound, stop the machine immediately, and inform relevant personnel and supervisors for detailed inspection.

8. Pay attention to observe whether there are large blocks exceeding the feed particle size requirements in the discharge pit. If it is found, stop the plate feeder immediately for treatment.

Company Introduction

FAQ

Q: What is the payment terms ?

A: 1.Total payment lower than 3000USD : 100% payment by T/T before delivery.

2.Total payment higher than 3000USD: 30% prepayment by T/T , after the seller finish the production process and buyer verify the

machine , 70% balance should paid before delivery.

3.Alibaba trade assurance L/C is also acceptable in special conditions.

Q: How long is the delivery time of your machine?

A: 1. The delivery time is within 20-30 working days.

2. But if the project is very large and clients have some special requirement about the equipment, the delivery time will be

extened.

Q: How long will the shipment takes ? (roughly)

A: 1. Africa : 30-45 days

Asia : 5-25 days

America : 15-40 days

Europe : 30-40 days

Q: How long is the warranty period about machine?

A: 1. Our machine warranty period is 1 year.

2. Wearing parts and problem coursed by worker's wrong operation are not included.

Q: Can you provide me a solution and quotation?

A: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage

of final products, etc.

A: 1.Total payment lower than 3000USD : 100% payment by T/T before delivery.

2.Total payment higher than 3000USD: 30% prepayment by T/T , after the seller finish the production process and buyer verify the

machine , 70% balance should paid before delivery.

3.Alibaba trade assurance L/C is also acceptable in special conditions.

Q: How long is the delivery time of your machine?

A: 1. The delivery time is within 20-30 working days.

2. But if the project is very large and clients have some special requirement about the equipment, the delivery time will be

extened.

Q: How long will the shipment takes ? (roughly)

A: 1. Africa : 30-45 days

Asia : 5-25 days

America : 15-40 days

Europe : 30-40 days

Q: How long is the warranty period about machine?

A: 1. Our machine warranty period is 1 year.

2. Wearing parts and problem coursed by worker's wrong operation are not included.

Q: Can you provide me a solution and quotation?

A: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage

of final products, etc.

Hot Searches