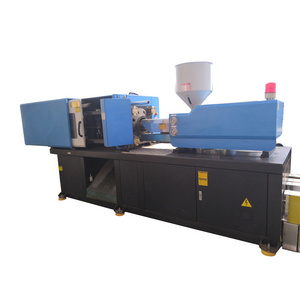

With advanced processing and testing equipment to process independently, SONLY not only ensures high precision for machine detail parts with short delivery time, but also meets the high standard customized requirements with multi-purpose.

- Product Details

- {{item.text}}

Quick Details

-

Ejector Number:

-

4+1

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

41 kN

-

Theoretical Shot Volume(cm³):

-

189 cm³

-

Injection Rate (g/s):

-

171 g/s

-

Injection Weight (g):

-

172.3 g

-

Screw Speed (rpm):

-

0 - 270 rpm

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

20.3

-

Distance between Tie Bars:

-

400x360 mm

-

Weight (KG):

-

3100 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

U100TSF9

-

Brand Name:

-

SONLY

-

Power (kW):

-

15 kW

-

Overall dimensions (LXWXH):

-

4.34m*1.24m*1.85m

-

Tank volume (L):

-

125

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

400mm

-

Distance between Tie Bars(Height)(mm):

-

360mm

-

Mold Height(mm):

-

120 - 360 mm

-

Ejector Number:

-

4+1

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

41 kN

-

Theoretical Shot Volume(cm³):

-

189 cm³

-

Injection Rate (g/s):

-

171 g/s

-

Injection Weight (g):

-

172.3 g

-

Screw Speed (rpm):

-

0 - 270 rpm

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

20.3

-

Distance between Tie Bars:

-

400x360 mm

-

Weight (KG):

-

3100 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

U100TSF9

-

Brand Name:

-

SONLY

-

Power (kW):

-

15 kW

-

Overall dimensions (LXWXH):

-

4.34m*1.24m*1.85m

-

Tank volume (L):

-

125

Specification

F9----One machine with multi function, comprehensive usage

|

SPECIFICATIONS

|

U100TSF9

|

|

|

|

||||

|

INTERNATIONALLY RECOGNIZED MODEL

|

300

|

|

|

|

||||

|

INJECTION UNIT

|

|

A

|

B

|

C

|

||||

|

SCREW DIAMETER

|

mm

|

32

|

35

|

38

|

||||

|

SCREW RATIO

|

L/D

|

24.1

|

22

|

20.3

|

||||

|

THEORETICAL SHOT VOLUME

|

cm3

|

134.2

|

160.6

|

189.0

|

||||

|

INJECTION PRESSURE

|

MPa

|

222.1

|

185.7

|

157.5

|

||||

|

THEORETICAL SHOT WEIGHT

|

g

|

122.2

|

146.1

|

172.3

|

||||

|

THEORETICAL INJECTION RATE

|

mm/s

|

140

|

140

|

|

||||

|

THEORETICAL SHOT WEIGHT

|

oz

|

4.3

|

5.1

|

6.0

|

||||

|

SCREW SPEED

|

rpm

|

270

|

|

|

||||

|

CLAMPING DEVICE

|

|

|

|

|

||||

|

CLAMPING FORCE

|

KN

|

1000

|

|

|

||||

|

TOGGLE STROKE

|

mm

|

320

|

|

|

||||

|

SPACE BETWEEN TIE BARS

|

mm

|

400x360

|

|

|

||||

|

MAX MOULD HEIGHT

|

mm

|

360

|

|

|

||||

|

MIN MOULD HEIGHT

|

mm

|

120

|

|

|

||||

|

EJECTOR STROKE

|

mm

|

100

|

|

|

||||

|

EJECTOR FORCE

|

KN

|

41

|

|

|

||||

|

EJECTOR NUMBER

|

|

4+1

|

|

|

||||

|

DIE HOLE DIAMETER

|

mm

|

125

|

|

|

||||

|

OTHER

|

|

|

|

|

||||

|

SYSTEM PRESSURE

|

MPa

|

17.5

|

|

|

||||

|

HETER POWER

|

KW

|

10

|

|

|

||||

|

TANK VOLUME

|

L

|

125

|

|

|

||||

|

MACHINE WEIGHT (APPROX.)

|

Ton

|

3.1

|

|

|

||||

|

OVERALL DIMENSIONS (LXWXH)

|

m

|

4.34x1.24x1.85

|

|

|

||||

|

SERVO DRIVE POWER

|

KW

|

15

|

|

|

||||

Through in-depth market research, Sonly team found that today's plastic products are made of a wide variety of materials, and the product process requirements are getting more and more higher, while the performance of conventional injection moulding machines cannot well suited to the individual needs of the market. In order to improve production efficiency and market competitiveness, customers have to chose special injection molding machines such as fruit baskets, bottle caps, eyeglass frames and fast speed machines. In the short term, these special injection molding machines are indeed better at meeting the need for efficient production of the special products, but in the long term, there are huge pitfalls. When the customer purchased a special injection molding machine, if the product material is changed or the market is updated, the special machine might be obsolete or takes high cost to change.

Many customers are no longer satisfied with these "narrow usage and inflexible" special injection molding machines. They are looking forward to a new machine with strong universality that could be adapted to a wide range of individual situations, significantly increase productivity and respond flexibly to market challenges. They not only require precise and stable equipment, but also want "One machine with multi function, comprehensive usage".

Sonly complies to the market development trend and understands the differentiated needs of customers, so we use new R&D platform to create this F9-Supersonic series injection molding machine.

The F9 series of injection molding machine is designed from extremely austere concept, with the main purpose of *One machine with multi function, comprehensive usage", it has a novel appearance, compact structure and excellent performance.

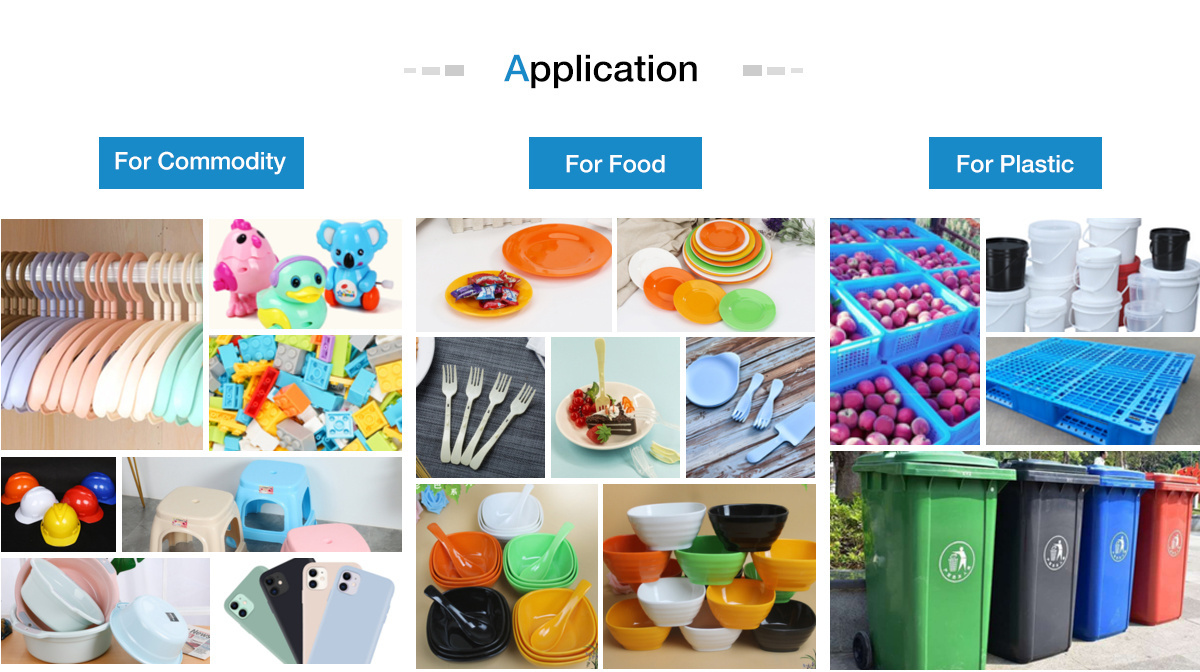

Applications

A

pplications

For Commodity

For Food

For Plastic

Platen Dimensions

Product Advantages

1. INDEPENDENT PROCESSING, FREE INNOVATION

2. SUPER RIGID TEMPLATE STRUCTURE, LESS MOLD ABRASION

Inside design of pin shaft shortens the length of mold clamping part, improves template rigidity and reinforces mould weight support. High rigid mold clamping unit design, comprehensively optimized parameters and force distribution ensure the stability, reliability and durability of the whole machine.

With the help of integrated hydraulic control device, the movable template is well supported and guided on the guide rack. It improves movement accuracy when the mold is very heavy, which achieve less mould abrasion and perfect mould protection. Therefore, the maintenance cost is always controllable and the benefit is better.

3. MORE EFFICIENT WIDE TEMPLATE DESIGN, SAVE COST FOR BIG SIZE MOLDS

F9 series machine tie bar space of larger compared with ordinary machine in same model, which has bigger space for mould. For example, the same product if by ordinary injection molding machine needs 168 tons, while by SONLY F9 supersonic series only need 140 tons.

4. EUROPEAN ROBOT INSTALLATION INTERFACE

European standard robot and signal plug installation interface reserved, which is convenient and efficient.

5. DOUBLE LAYER INJECTION GUIDE RAIL STRUCTURE, NO RESISTANCE AND NO DISASSEMBLY

F9 series machine adopted double-layer guide rail, the upper layer is linear guide rail which has better rigidity. The injection movement is smooth and accurate without friction resistance.

It also improves the repetition

accuracy

of products to less than 0.5% and increases injection speed by 10%-40% with low noise. The lower guide rail is in a standard design with enough length, no need to disassemble out the screw for replacement as before, just move it forward or backward, which is convenient for users to change screw & barrel with different diameters. It can be applied to all kinds of screw L/D ratio, the compatibility is stronger (such as PC material, PET material, etc.), to achieve a multi-purpose machine, no need modification.

6. BALANCED DOUBLE CYLINDER INTEGRAL INJECTION MOVEMENT STRUCTURE, ACCURATE AND STABLE, AVOID MELTED MATERIAL LEAKAGE

F9 series machine tie bar space of larger compared with ordinary machine in same model, which has bigger space for mould.

For example, the same product if by ordinary injection molding machine needs 168 tons, while by SONLY F9 supersonic series only need 140 tons.

7. NON-WELDED MAIN OIL PIPE DESIGN, LEAK-PROOF AND CLEANER

Non-welded pipe circuit ensures long-term usage without oil leakage by weld crack and reduces oil pollution. High precision bypass filter device, self sealing oil suction filter, non welded pipeline+ integral oil cylinder assembly can be selected to improve the oil cleanliness. New oil circuit design, beautiful appearance,fast and stable internal oil circuit, reducing cost and increasing efficiency.

It is equipped with advanced special computer controller for injection molding machine (Techmation series), one button 12 inch aluminum milling operation panel, large operation screen, which is intuitive and easy to use and has high-end and durable performance meanwhile with beautiful and atmospheric appearance. The secondary development of the operating program has greatly improved the scanning cycle, reserved enough 10 points, open programming platform, high-end multipoint touch screen is optional. It can support multiple data interface protocols and provides cloud services for remote assistance and maintenance (optional).

9. NEW GENERATION SERVO SYSTEM, MORE EFFICIENT

Super fast response can reach the highest pressure in 27ms. Compared with the same model/specification ordinary machine, its production molding time is about 3s faster, which shorts the cycle time effectively and improves production efficiency. It is especially suitable for transparent products. With high system pressure, it can use for a wider range of products.

10. COMPREHENSIVE SERVICE, ONE MACHINE FOR MULTI-PURPOSE, STRONG UNIVERSALITY

A good machine must be capable to face the challenges of plastic processing industrial market changes. We have a very professional and comprehensive service system, so that you can obtain high-performance improvement and optimization tools at any time, as well as comprehensive professional training, to achieve one machine with the maximum lifetime.

Why Choose Us

A

bout us

Our company is a high-tech enterprise intergrate development, manufacturing, and sales.

· Since 2000

· Factory area: 60000㎡

· Annual production: 3000 sets precision injection molding machine

· BSCI & ISO 9001:2008 certified manufacture

· The member unit of China Plastics Machinery Industry Association

Our company produce:

· SONLY U-TS high-grade precision injection molding machine

· 50T to 3400T servo injection molding machine

· Customized PET bottle injection molding machine

· PP-R coupler injection molding machine

· PVC pipe fitting injection molding machine

· Fruit basket injection molding machine

· Double colored plastic injection machine

We provide customerized service according to customer's requirements, please feel free to contact with us!

FAQ

Q1: Are you a manufacture or a trading company?

A1: We are a manufacturer in Ningbo city, Zhejiang Province, China

Q2: What's your payment term?

A2: 30% TT as deposit, 70% TT before shipment, and other payments can also be negotiated

Q3: What should I do if there is a quality problem?

A3: We have guarantee 1 year for machine, 6 months for screw and barrel (not include recycle or reclaimed material). All the spare parts are made by ourselves, so we can control the quality and cost totally.

Q4: What's your delivery time?

A4: within 30 working days after received deposit. (U98TS - U438TS)

within 60 working days after received deposit. (U508TS - U780TS)

within 90 working days after received deposit. (U1080TS - U1850TS)

within 120 working days after received deposit. (U2400TS - U3400TS)

Q5; How to install the machine and use the machine?

A5: We can send engineer to your factory for worker training and machine installation.

Q6: I want to make a plastic product, but I don't know how to choose a suitable machine model, what should I do?

A6: Please feel free to tell us about the product detail information, such as size and weight, how many output you prefer per hour. We will help you to make good proposal with nice price.

Hot Searches