- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hyman

-

material:

-

100% Natural Marble

-

Size:

-

Customized Size

-

Packing:

-

Carton + Waterproof plastic + Fumigation Wooden Crate

-

Usage:

-

Interior Wall, Ceiling etc

-

Thickness:

-

1-10mm

-

Finished:

-

Polished, Honed and Brushed

-

Sample:

-

Freely Provide

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Home Office

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hyman

-

material:

-

100% Natural Marble

-

Size:

-

Customized Size

-

Packing:

-

Carton + Waterproof plastic + Fumigation Wooden Crate

-

Usage:

-

Interior Wall, Ceiling etc

-

Thickness:

-

1-10mm

-

Finished:

-

Polished, Honed and Brushed

-

Sample:

-

Freely Provide

Product Description

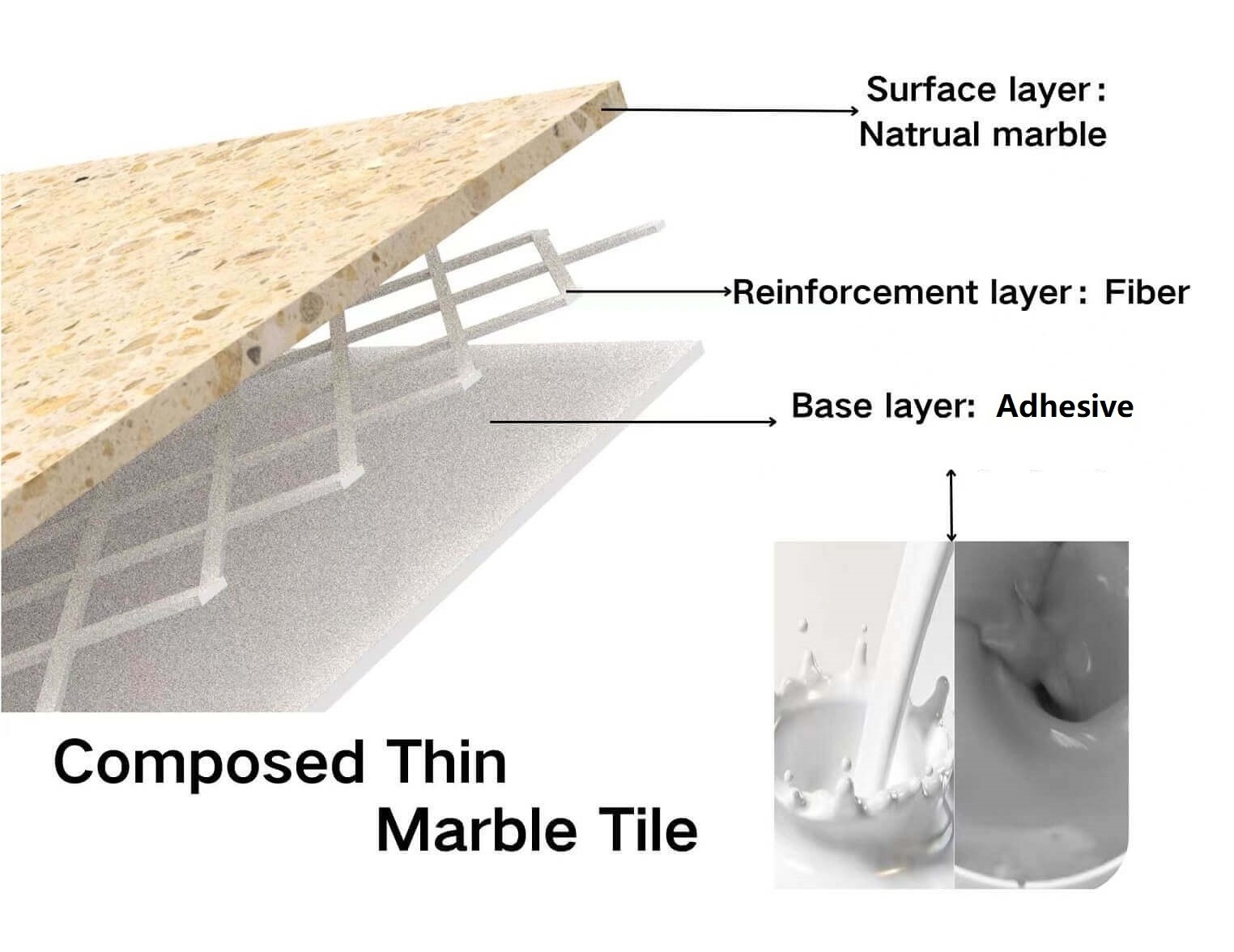

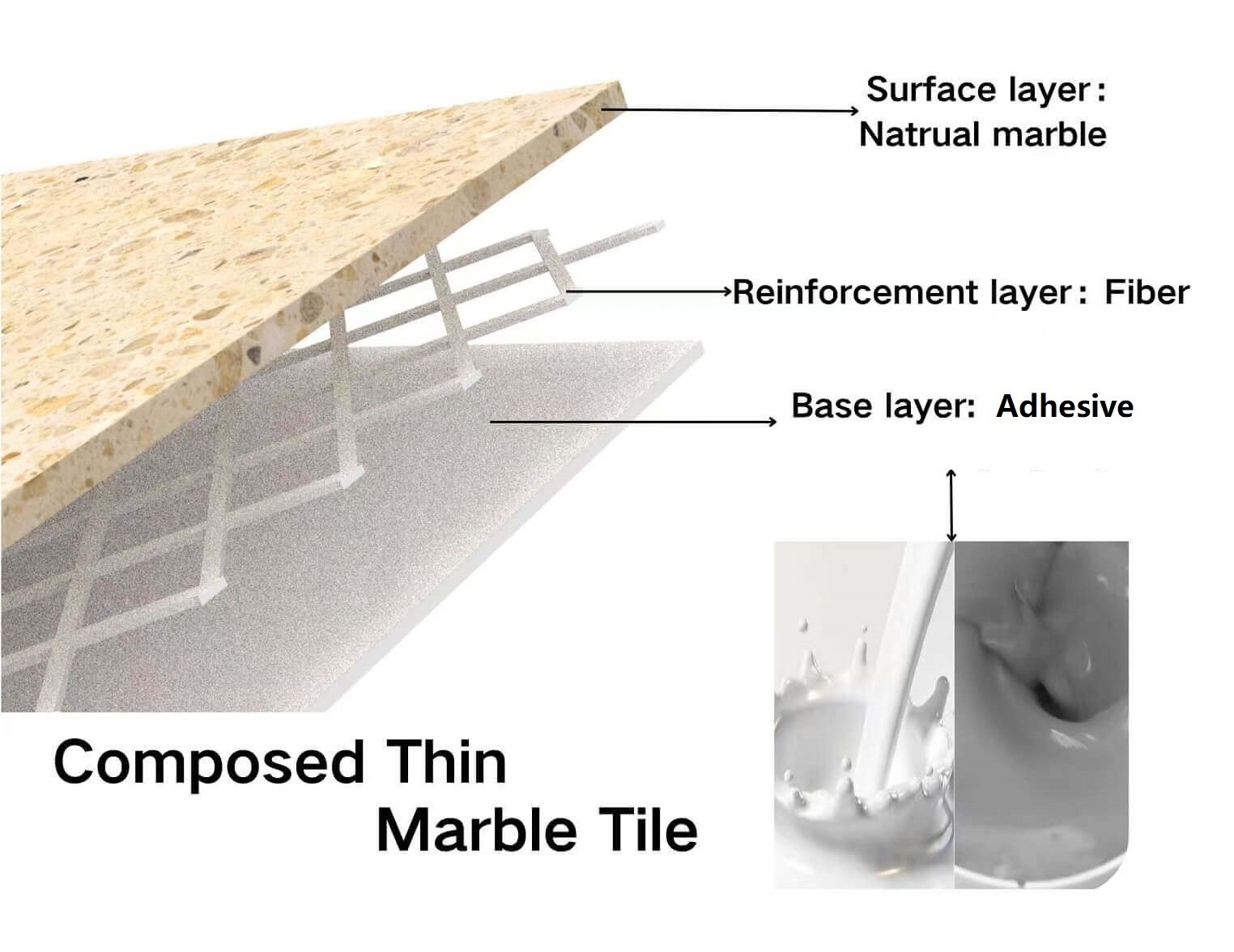

What is lightweight Marble ?

It is a new building decoration material that combines ultra-thin natural stone plates with a thickness of 6.5mm with glass fiber, carbon fiber, aramid and other reinforcing materials through special clay. Its comprehensive performance is greatly improved.

|

Surface layer:

natural marble

|

Thickness:

4.5mm

|

|

Reinforcement layer:

glass fiber, carbon fiber, aramid

|

Thickness:

0.08mm-0.2mm

|

|

Back layer:

Special high-strength waterproof cement

|

Thickness:

0.5mm-2mm

|

Advantages of Lightweight Marble

Super impact resistance

Due to the comprehensive effect of the reinforcement layer, the cement layer and the optimal thickness setting, the KN board has super impact resistance, which can ensure that the KN board is not prone to cracking and breakage during production, transportation, installation and use, and solves the fragile problem of natural marble.

Solve easily cracking, Solve yellowing problem etc.

Self-leveling hard foundation + thin pasting technology solves the hollowing problem of the base layer and effectively solves the stubborn problem of easy cracking.

The waterproof cement used in the KN board's cement layer and paving has excellent waterproof properties, effectively blocking water vapor in the bottom layer and preventing iron elements from turning yellow due to oxidation.

Waterproof cement is used for the cement layer and paving of KN board. Its alkaline substances are greatly reduced. At the same time, its good waterproof performance can effectively block the alkaline substances from the bottom layer and prevent the stone surface layer from returning to alkali lesions.

Lightweight and weight loss

KN board weighs 3-15kg/㎡, which is only about 20% of traditional stone. It can derive many excellent properties.

Transportation costs are significantly reduced, which is especially beneficial to product exports;

Secondary transportation is easier and more efficient, and the cost is greatly reduced;

Breaking through the restricted area of traditional stone use, it can be used in ceilings, furniture and home appliance facades and other fields.

|

Marble Size

|

Thickness

|

|

300*600 mm

|

6.5mm

|

|

1200*1500 mm

|

6.5mm

|

Detailed Images

Hundreds of patterns for you to choose. Feel free to contact us to choose!

Application

Certificate

Packing&Shipping

Thin tiles are packed every 8PCS/CTN or foam boxes, and then in strong wooden crates.

Thick tiles are packed directly in wooden crates, with safe support to protect the surface& edges, and prevent rain and dust. Slabs are packed in strong wooden bundles.

Company Introduction

Contact us

FAQ

Q1 Lightweight Marble tile/slab is so thin, is it man-made?

A: They specifically refer to ultra-thin natural stone boards. All are made from raw materials mined from mining areas around the world and processed through a series of processes. They are natural stone products, not artificial stones.

Q2

Lightweight Marble tile/slab

is so thin, is it particularly easy to break when used?

A: It adopts a new thin lamination process. The chip resistance performance of marble laid according to the requirements is much better than that of traditional thick boards. For specific reasons, please refer to the above product introduction.

Q3

Lightweight Marble tile/slab

is so thin, will it be worn out during subsequent use and maintenance?

A: During the entire service life of natural stone, it will only be partially worn during the first crystallization after paving. The main reason is that the height difference between the flat surfaces is only about 0.5-1mm in order to achieve the overall mirror effect. After the crystallization is completed, there is a transparent protective layer on the surface of the marble. For this reason, the stone itself will not be worn during subsequent use and maintenance. On the contrary, after each maintenance, the protective layer will gradually thicken (about 0.1mm/time) .

Q4

Lightweight Marble tile/slab

is so thin, can it be chamfered, and how to deal with the external corners?

A: It can be chamfered at 45° just like traditional thick boards. Since the board is ultra-thin, you need to pay attention to skills and choose appropriate chamfering equipment when chamfering. For the treatment of the external corner line, you can choose the direct crabapple corner process, which is simple, efficient and not easy to chip. You can also choose 45° splicing or chamfering.

Q5 Having said so many advantages of

Lightweight Marble tile/slab

, what are its disadvantages?

A: As a brand-new product, it is relatively unfamiliar to customers, designers, and construction workers. Their understanding of the product requires a process. For this reason, the communication cost of the current product is too high. In addition, paving construction workers do not understand the performance of the product and need training and proficiency in the process.

Q6 Can you cover the construction?

A:Yes. At the same time, we will also arrange training to allow more paving workers to master the skills of

Lightweight Marble tile/slab

paving.

Hot Searches