- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

volumetric doser

-

Type:

-

horizontal screw conveyor

-

Material:

-

304 stainless steel

-

Structure:

-

horizontal conveyor

-

Load Capacity:

-

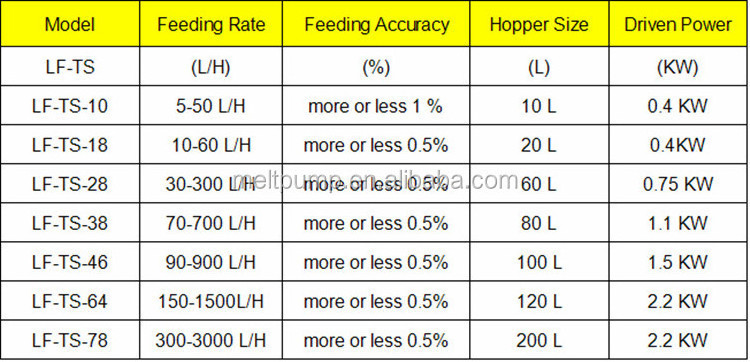

0-3000L/H

-

Feeding Range:

-

pellet, free flowing power, fibrous materials...

-

Feeding Accuracy:

-

more or less 0.5-1%

-

Load Cell:

-

Mettler Toledo

Quick Details

-

Machinery Capacity:

-

400-4000L/H

-

Weight:

-

320 KG

-

Key Machines:

-

loss in weight feeder

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

volumetric doser

-

Type:

-

horizontal screw conveyor

-

Material:

-

304 stainless steel

-

Structure:

-

horizontal conveyor

-

Load Capacity:

-

0-3000L/H

-

Feeding Range:

-

pellet, free flowing power, fibrous materials...

-

Feeding Accuracy:

-

more or less 0.5-1%

-

Load Cell:

-

Mettler Toledo

1). OEM services provided;

2). Excellent quality assurance;

3). Fast delivery;

4). Worldwide dealer or agent needed.

BATTE Melt Pump Zhengzhou Co., Ltd is a professional manufacturer and supplier for loss-in-weight feeding system. Our loss-in-weight feeding system with high accuracy can well meet the the demands from plastic, rubber, chemical, food, powder, pharmaceutical industry etc.

BATTE feeding system include loss-in-weight feeder, dosing feeder, volumetric doser, multi-component formular feeder and so on. We can supply professional feeding system for various kinds of materials. Furthermore, our networking loss-in-weight feeding system can support the factory unified database to reach the demands such as hygiene , explosion-proof, water-proof, corrosion-resistance etc.

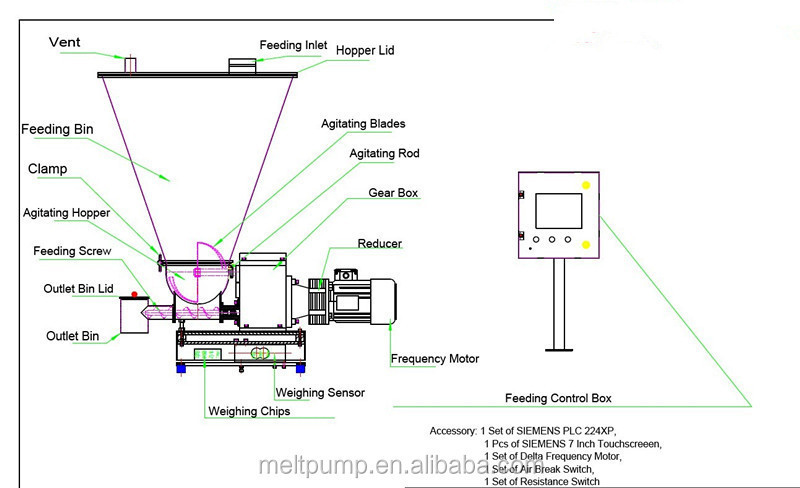

Main Component for BATTE volumetric doser

Technical Parameter for BATTE volumetric doser (LF-TS Series)

The Advantages of BATTE volumetric doser (LF-TS Series)

1.

Generous and beautiful appearance;

2. Small volume;

3. Wide measuring range;

4. Touchscreen output and customized input system designed for easy operation;

5. Low noise;

6. High stability;

7. Easy to clean and maintain;

8. Excellent control system;

Quality Control System

• Fixed Equipments for Q/C

• Qualified Adequately before Reaching Warehouse

• Randomly Checking Machines before Shipment

Our Value-added Service Package

1. Installation Services : During the period of installation and debugging, we shall offer training about effective operation and maintenance.

2. Technical Services: Our company has been devoting ourselves into offering custom transforming projects for our worldwide clients in the field of medical, chemical engineering, plastics, rubber industries etc.

We can assist our clients to solve all kind of technical problems with our capable technician team, and we own adequate experience for production line transformation as well as formula feeding arrangement.

3. Warranty Services : We offer free after sale service except the engineers' traveling expense for any quality problem occurs during our 12 months warranty period.

Some Successful Cases We Handle for Our Global Clients