- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5500mm*3500mm*2300mm

-

Motor Power (kW):

-

10

-

Model Number:

-

B32

-

Weight (T):

-

10

-

Marketing Type:

-

Hot Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

630KN

-

Color:

-

customization

-

Product name:

-

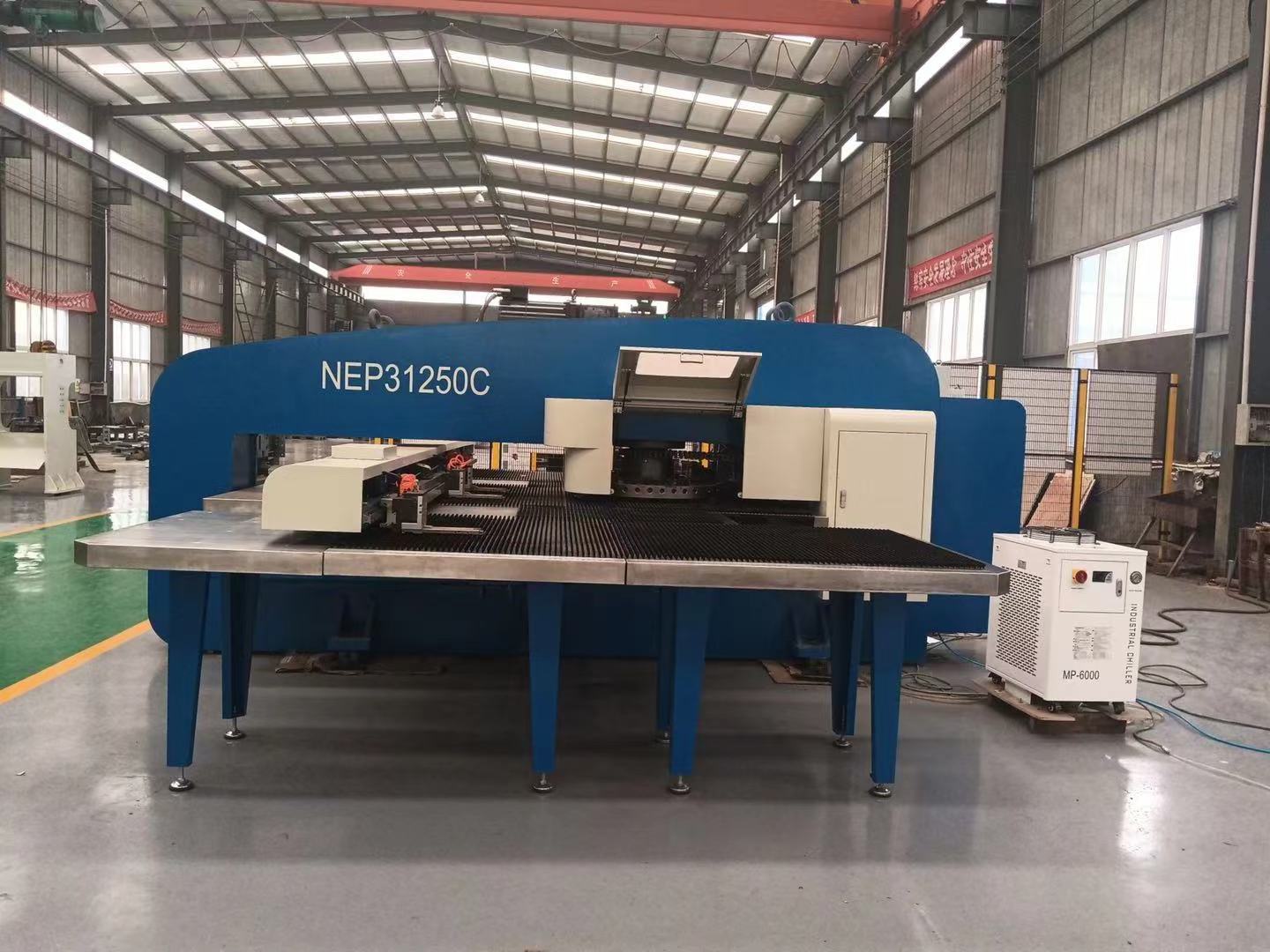

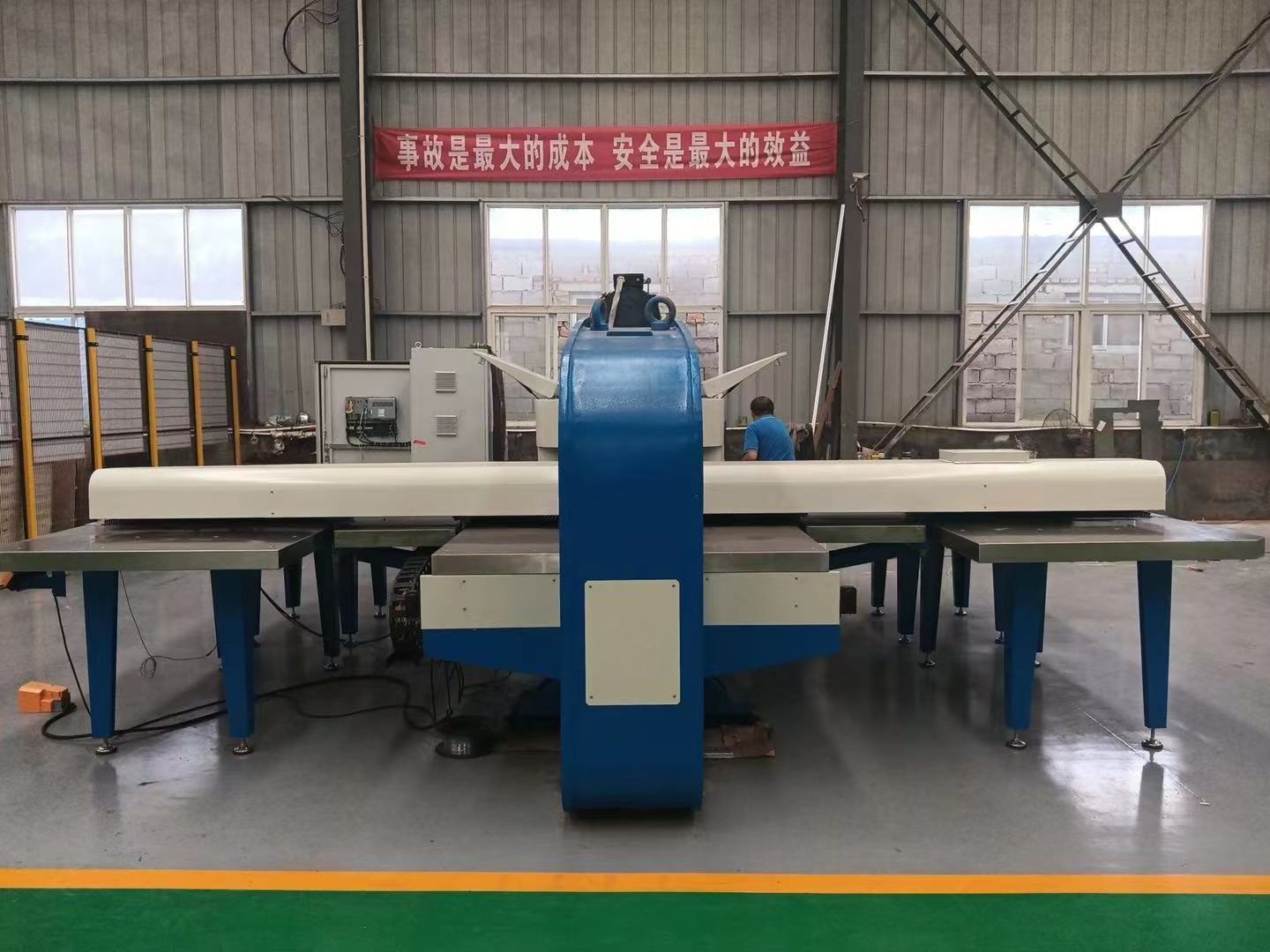

cnc punching machine

-

Usage:

-

hardware products

-

control:

-

plc

-

Application:

-

Metal Sheet Stamping

-

Function:

-

Steel Metal Punching

-

Keyword:

-

Automatic Punching Machine

-

Type:

-

C-Type Structure

Quick Details

-

Slide Stroke (mm):

-

50mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Besco

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5500mm*3500mm*2300mm

-

Motor Power (kW):

-

10

-

Model Number:

-

B32

-

Weight (T):

-

10

-

Marketing Type:

-

Hot Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

630KN

-

Color:

-

customization

-

Product name:

-

cnc punching machine

-

Usage:

-

hardware products

-

control:

-

plc

-

Application:

-

Metal Sheet Stamping

-

Function:

-

Steel Metal Punching

-

Keyword:

-

Automatic Punching Machine

-

Type:

-

C-Type Structure

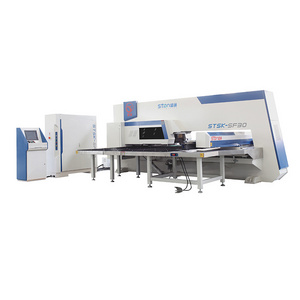

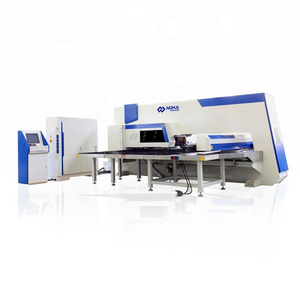

Product Overview

Product Application

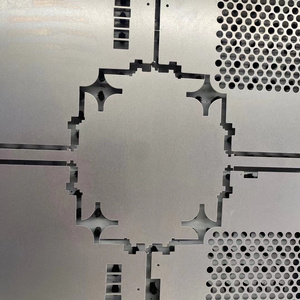

Applied to the sheet punching, stretching and other shapes of hole machining. It is suitable for batch or sample

processing to reduce mold investment and reduce production costs. It is mainly used in a variety of high and lowvoltage

switchgear, control panel, case, cabinet, shell, metal furniture, kitchenware and advertising industry

1,International pneumatic components and electrical components to ensure the reliability of the overall performance.

2,CNC turret Punching machine Using high-quality production of large lead ball screws, linear guides ensure that the transmission accuracy.

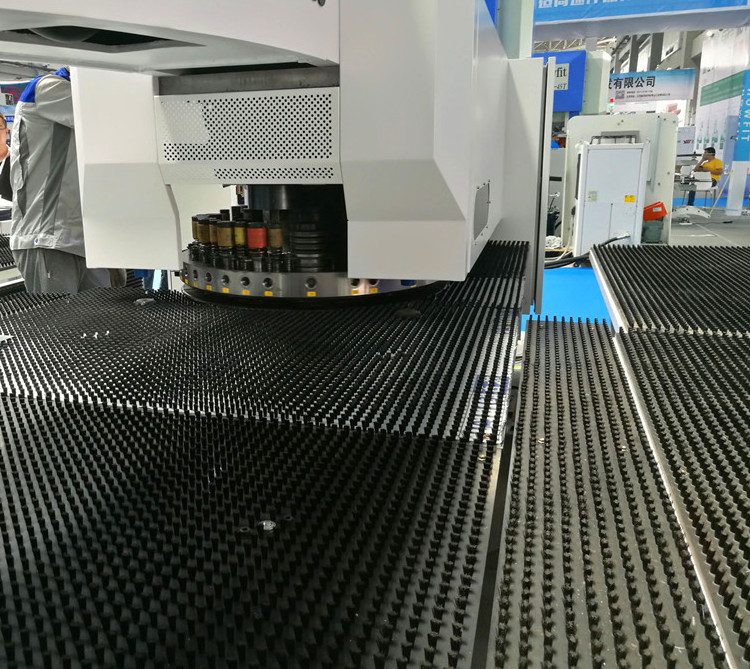

3,With a hard brush and ball mixing table, the machine not only reduces the noise and vibration at work, but also played a verygood surface protection for processing sheet.

4,CNC turret punching machine Using the O-closed steel welded body, by the second aging treatment, making removal more thoroughly stress.

5,Use floating clamp, clamping force big, stable feeding; integral dovetail carriage, rigid, clamp easy to move.

processing to reduce mold investment and reduce production costs. It is mainly used in a variety of high and lowvoltage

switchgear, control panel, case, cabinet, shell, metal furniture, kitchenware and advertising industry

1,International pneumatic components and electrical components to ensure the reliability of the overall performance.

2,CNC turret Punching machine Using high-quality production of large lead ball screws, linear guides ensure that the transmission accuracy.

3,With a hard brush and ball mixing table, the machine not only reduces the noise and vibration at work, but also played a verygood surface protection for processing sheet.

4,CNC turret punching machine Using the O-closed steel welded body, by the second aging treatment, making removal more thoroughly stress.

5,Use floating clamp, clamping force big, stable feeding; integral dovetail carriage, rigid, clamp easy to move.

PRODUCT SPECIFICATIONS

|

Name

|

Unit

|

Parameter

|

|

Nominal Force

|

kn

|

300

|

|

range of one time processing

|

mm

|

1500*1250/2500*3000/3500/5000

|

|

Max movement speed

|

mm/min

|

40-80

|

|

Max thickness of workpiece

|

mm

|

6

|

|

mold station

|

station

|

12/24/32

|

|

self rotated mold

|

set

|

2 ( C station) optional

|

|

process precision

|

mm

|

0.1

|

|

punch frequency

|

hpm

|

160/240 (double speed)

|

Main Features

1, Standard of thick, using intemational 85 series die, the long guiding, strong versatility, high stability, lateral positioning

taper pin

2. C-open type bed or O-type closed bed, good rigidity, small deformation, stable feeding support

3, CNC punching dedicated system, WINDOWS interface, pure Chinese prompt, easy to learn, easy to operate

4. The span of bed rail is large and level. Support is good to ensure precision and high-speed feed stabl

5. The newly added software automatically search the clamped position, without artificial participation, high accuracy rate.

1, Standard of thick, using intemational 85 series die, the long guiding, strong versatility, high stability, lateral positioning

taper pin

2. C-open type bed or O-type closed bed, good rigidity, small deformation, stable feeding support

3, CNC punching dedicated system, WINDOWS interface, pure Chinese prompt, easy to learn, easy to operate

4. The span of bed rail is large and level. Support is good to ensure precision and high-speed feed stabl

5. The newly added software automatically search the clamped position, without artificial participation, high accuracy rate.

More details

Our Service

SALES AND SERVICE NETWORK

FAQ

GUARANTY PERIOD

One year free , a lifetime warranty after-sale support .

GUARANTY COVERS

Main parts of the machine , wearing parts not included .

PARTS DELIVERY

Within 5 days by DHL / Fexed .

TECHNOLOGY SUPPORT

Techanicans are available for oversea service .

INSTALLATION & COMMISSIONING

Seller can arrange the techanicals to do the installation for buyer if it is necessary

One year free , a lifetime warranty after-sale support .

GUARANTY COVERS

Main parts of the machine , wearing parts not included .

PARTS DELIVERY

Within 5 days by DHL / Fexed .

TECHNOLOGY SUPPORT

Techanicans are available for oversea service .

INSTALLATION & COMMISSIONING

Seller can arrange the techanicals to do the installation for buyer if it is necessary

Hot Searches