- Product Details

- {{item.text}}

Quick Details

-

Power:

-

50-360kw

-

Weight:

-

7000 KG

-

Dimension(L*W*H):

-

22mx2mx4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Materials:

-

stainless steel food grade

-

Product name:

-

Dry dog food making machine

-

Technology:

-

Extrusion

-

Process for:

-

Pet/Dog/pet/cat/fish and so on

-

shape:

-

variable according to the die

-

Capacity:

-

150kg/h,250kg/h,600kg/h,1Ton/h,3Ton/h, 5Ton/h

-

Formula:

-

Normal formula will be supplied free

-

Contact skype:

-

candice20115

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SBN

-

Voltage:

-

200-440V 50-60HZ

-

Power:

-

50-360kw

-

Weight:

-

7000 KG

-

Dimension(L*W*H):

-

22mx2mx4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Materials:

-

stainless steel food grade

-

Product name:

-

Dry dog food making machine

-

Technology:

-

Extrusion

-

Process for:

-

Pet/Dog/pet/cat/fish and so on

-

shape:

-

variable according to the die

-

Capacity:

-

150kg/h,250kg/h,600kg/h,1Ton/h,3Ton/h, 5Ton/h

-

Formula:

-

Normal formula will be supplied free

-

Contact skype:

-

candice20115

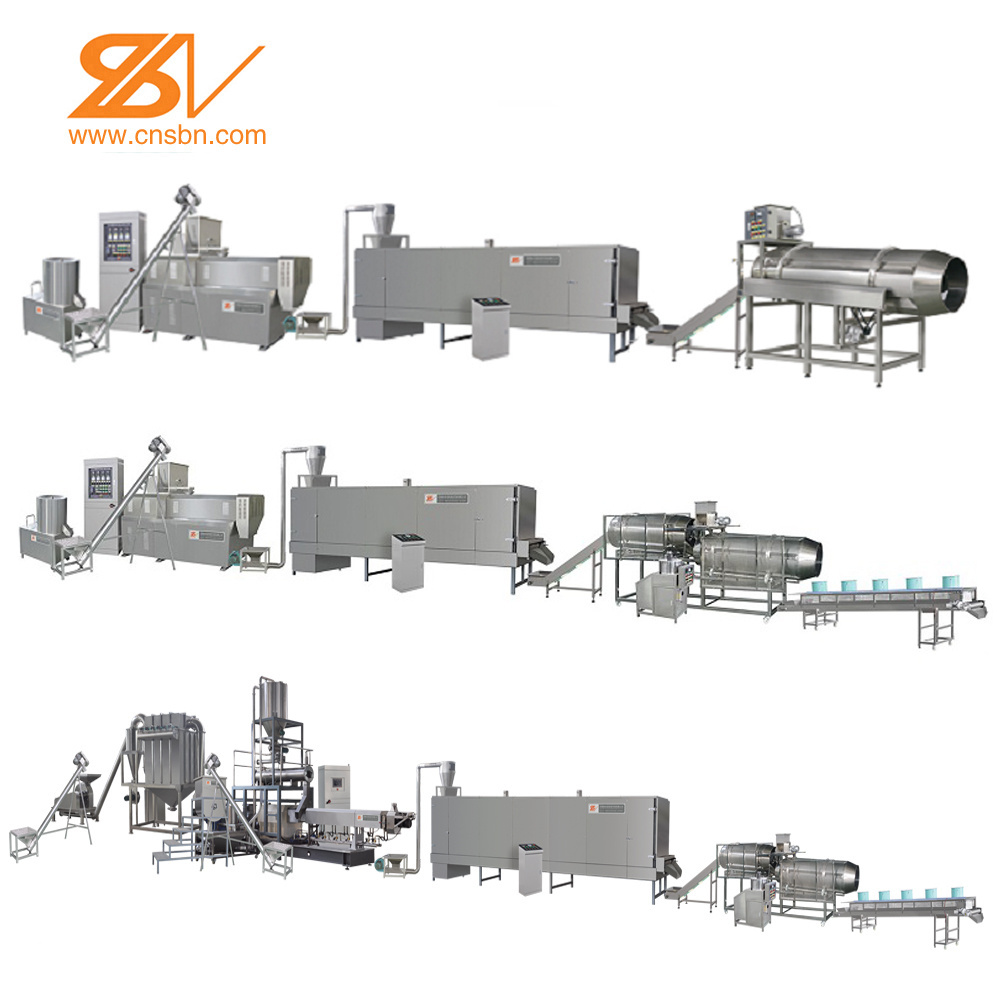

Large capacity Dry pet food production line

1. With the rapid development of national economy, all kinds of pet food are increasing and have a big market. Meanwhile it has a tendency of commercialization and formalization. There is great difference between the pet food and the traditional feeding way .The pet food is close to the human beings food in the fine level, the health index and the nutritional ingredient, some of them request more highly than human beings .The nutrition of inflated food is absorbed more easily.

1.Raw material : adopts corn flour, rice flour, soya flour,etc as raw materials.

2.Machine materials:

All the machines which connecting the raw material are made by stainless steel and mild steel.

3.Capacity:

120-150kg/h; 220-250kg/h; 400-500kg/h;1Ton/h, 3Ton/h, 5Ton/h.

4.Parameter:

|

SLG 65-III Dry dog food making machine |

SLG70-II Dry dog food making machine |

SLG85-II Dry dog food making machine |

SLG95 Dry dog food making machine |

SLG120 Dry dog food making machine |

||

|

Installed capacity |

80KVA |

105KVA |

115KVA |

250KVA |

350KVA |

||

|

Power |

58Kw |

70Kw |

80Kw |

175kw |

250kw |

||

|

Output |

140-160kg/h |

240-260kg/h |

500-600kg/h |

800-1000kg/h |

2-3Ton/h |

||

|

Dimension |

22×2×4m |

24×2×4m |

28×2×5m |

40X2X5m |

55X2X5m |

5.Main machine list:

1. Crushing

Raw material first are cushed by the Pet food crusher.

2. Mixing

Powdery feed materials need to be mixied thoroughty in the mixer to ensure a high-quality of nutrition feed.

3. Extruding

It is the main machine for producing the fish feed. Materials are extruded and cut and mixed by screw in the machine barrel. The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes.

4. Drying oven

Fish feed from extruder need to lower high moisture and temperature. So dryer oven should be equipped in the production line.

5. Flavoring machine

For acquiring better smell and taste, the oil sprayer machine cn be used to spraying oil to the surface of fish feed which coming out from the dryer.

6. Cooling

Hot products are soft and easily broken, which can result in a high percentage of fines. This cooling conveyor is cooling type that commonly used in feed industry currently.

7. Packing

The pet food are packaged in bags for further transporting and storage. Here you can opt the feed packing machine wichi is suitable for weighting and bagging feed.

6.Sample photos with different mold:

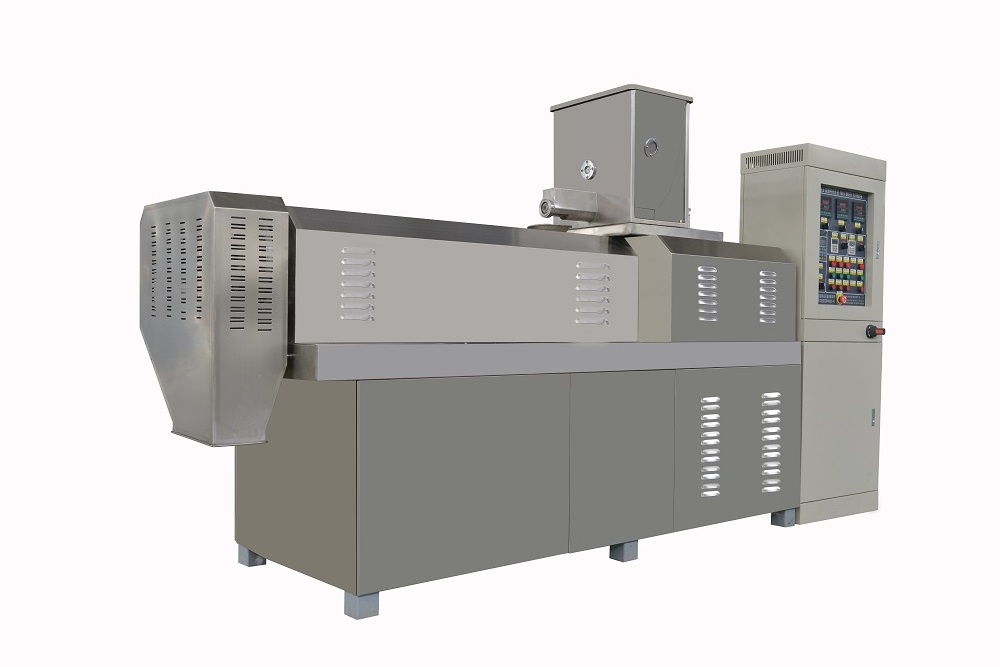

Name:

SLG Double Screw extruder

Function:

Extrude and cook raw material into different size and shapes

Name: Dryer

Function: There are three layer inside,each layer is 5 meters long, it can save space and energy. Electricity heating,used to bake and dry food.

Name: Whole processing line

Function:

Material mixing with water → material conveying → extruding → drying → oil spraying → flavoring → cooling → Storage

For the spares before put in storage, we will make a strict test , and we will test the whole machine line before shippment.

Saibainuo Company engages in the technical research of pet food machine, artificial rice machine, etc. in order to let our pets have superior foodstuffs to sell in the market. We can improve client’s equipment and provide related training on new advanced technique. We can also make special designs for special products and materials according to pet special requirements.